Various forming and sealing techniques are used to incorporate aluminum foil 7 micron into liquid packaging. Common methods include flow wrap where the foil is laminated to film and rolled around the product, next-generation three-side seal pouches for cartons, and cold seal lid foil that rolls over roll stock-shaped containers and cartons. The flexibility of the Aluminum Foil 7 Micron Foil gauge enables intricate shapes for stand up pouches. Retort capabilities have expanded the use of steaming sterilized feeds. Superior formability allows for tighter tolerances for capless and dispensing packages.

With the increasing global demand for long-life perishable materials, Aluminum Foil 7 Micron continues to evolve. Advances target lightweight packages through downgauging with barrier-enhancing substrates or coatings that compensate for their permeation barriers. The deposition and treatment of nanolayers improve strength and thermal resistance. Additional printing increases shelf front appeal and the message for recyclability increases uptake. Overall, the flexibility and functional upgrades with the high performance qualities of Aluminum Foil Flexible Packaging aluminum foil cement its importance for affordable liquid packaging.

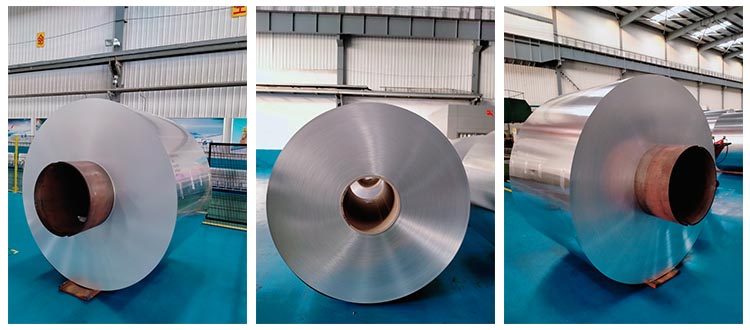

Aluminum foil 1235 8079 is a highly versatile packaging material suitable for many flexible packaging applications and formats. Flexible packaging aluminum foil provide superior moisture and gas barrier protection to paper, film and coated paperboard substrates. Downgauging below 10 microns, the multilayer structure can reduce material while maintaining performance. Adhesive coatings and printing technology bind foil evenly through complex packaging lines. Lamination to bioplastics derived from agricultural residues further enhances sustainability.

Consumer trends favoring extended shelf life and portable on-the-go packaging drive innovation with aluminum foil. Standup pouches, sachets, lidded cups and containers leverage its formability. Retort and aseptic sterilization processes use the barrier integrity of the foil layer. Barrier coatings have properties such as odor or light resistance. Emerging hybrid sheet formats consisting of foil composite webs offer product designers more options for graphics and consumer messaging. The research aims to develop recyclable one-component structures by combining foil and film layers.

As global supply chains lengthen, packaging integrity remains mission critical. Aluminum foil continues to inspire science with the addition of renewable nanoparticles while maintaining nutrition, freshness and flavor. The self-healing coating repairs micro-defects which protects the content. Enhanced metallization deposition and surface treatment enhance the barrier performance of various polymer films. Such continued improvements cement the role of aluminum foil protecting valuable commodity products in the broader flexible packaging market in the future.

Aluminum Foil 1235 is well suited for cosmetic packaging due to its lightweight, structureable and barrier properties. The thin flexible foil protects the formulas from degradation due to air, light and moisture. It can be laminated onto a variety of substrates or formed into aesthetic containers, lids, sachets and pouches on its own. Important for preserving cosmetics, the ultra-thin 7-10 micron foil gauge minimizes material while maintaining barriers. Surface printing or metallized coatings imbue customization. Retortable laminate structure enables sterile skin care.

Flexible Packaging Aluminum Foil enables on-trend single use and travel size cosmetic formats. Crease-proof features allow sachets, compact, and flexible pouches. extrusion or gluing to form a lid film. Custom foil strips or stamped shapes adorn palettes and organizers. Metalization enhances the holographic effect. Biodegradable peelable lid foil continues product development. Research targets antimicrobial enhancements to foil barrier laminate structures for self-healing defects, passive gas scavenging, and optimal product protection. Developing recyclable solutions that include identification markers supports the sustainability mandate. Overall, the formability, lightweight characteristics and barrier function of aluminum foil remain integral to luxury and mass market cosmetic packaging worldwide.

Flexible aluminum foil finds applications in many industries due to its versatility. In food packaging, foils laminated on plastic or paper substrates provide optimal oxygen, moisture and grease resistance for storage of everything from snacks and frozen foods to fresh bread and ready-to-eat foods,aluminum flexible foil for cosmetics packaging.Medication blister packs and medical device wraps depend on its barrier protection. Aluminum Foil 7 Micron Foil wrap and containers enhance food storage at home. Its light weight and moldability make foil indispensable for household aluminum products such as pans, roasting trays, and foil wrap.

Beyond consumables, flexible foils have applications in the industrial and construction markets. Extruded into shape, anodized, or bonded to nonmetallic materials, foils provide lightweight strength for applications such as radiant barrier insulation,aluminum flexible foil for cosmetics packaging, HVAC ducting, roof underlayments, and architectural facades. Its barrier properties proved useful for cable wrapping, pipe insulation, and protective sheeting. Other major sectors using flexible foil include electronics, lighting, and automotive where it finds use in EMI shielding, heatsinking, and as a high temperature tolerant material.

Continuous product innovation targets new applications. Downgauging and extended barrier packaging increase shelf life for perishables. Surface treatment improves thermal resistance and recyclability. Self-healing coatings and nanolayer addition maintain package integrity. Adaptability for hybrid composite structures or integrations with IoT sensors or RFID tags unlock smart capabilities. Overall, the lightweight, customizable, non-corrosive and effective barrier characteristics of aluminum foil ensure its prevalence in many mass market product segments for years to come.

Flexible foils find important applications in the medical field due to their lightweight, inert and flexible properties. Thin foil laminate provides sterile barrier packaging for devices, tools and supplies. Common medical uses include IV and surgical kit wraps, specimen pouches, dressings, and packaging overwraps. Its tight tolerances also allow complex structures for custom trays and instruments. Retortable foil laminate enables high temperature sterilization. Research develops antimicrobial foils and self-healing coatings that enhance infection control.

Advanced metallization and the emergence of composite foil solutions have enabled new high-technology applications. Flexible circuits use foil as a weight-saving yet highly conductive substrate. Vapor deposited aluminum has allowed Aluminum Foil Jumbo Roll in plastic creating a heat resistant conductive surface. Self-adhesive foil acts as a shield for electronics or provides a lightweight grounding material. The invention of foil is also used in capturing energy. Anodized aluminum foil acts as a transparent electrode in photovoltaics. Etching allows miniature radiator designs. All of these diverse applications benefit from foils that meet performance demands while maintaining flexibility, formability and weight-saving benefits.