High-quality aluminum foil 1235 is well regarded for its exceptional purity and lamination ability. There are multiple advantages of laminating using aluminum foil 1235, including improved heat resistance, compatibility with different substrates, and barrier protection.

The 1 series, of which the 1235 alloy is a part, provides better surface conditions than other alloys. This foil's distinctive design satisfies the rigorous requirements of the lamination process, providing the best possible adhesive and sealing properties for a variety of packaging materials.

The 1235 series of aluminum foil is well known for its exceptional lamination performance and purity. A variety of commodities may be packaged perfectly using it thanks to its strength, flexibility, and barrier qualities. This adaptability also includes flexible packaging.

In the food, beverage, pharmaceutical, and industrial sectors, using 1235 aluminum foil—which is ideal for preserving the integrity and quality of packaged goods—may be beneficial. Because of its resilience to severe light, humidity, and temperature changes, it's a good option when flexible packaging is needed.

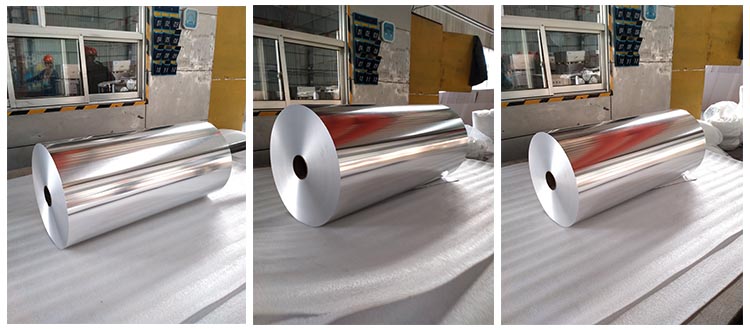

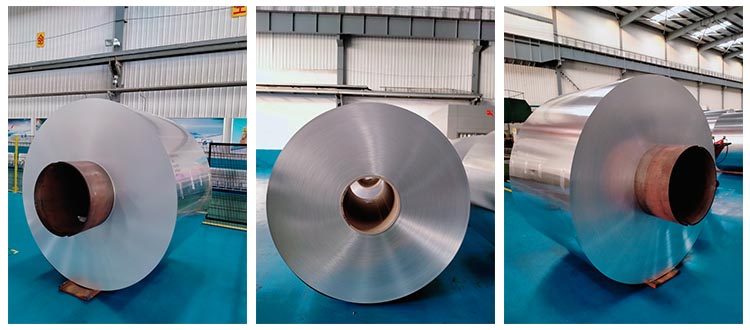

Large Rolls Of Aluminum Foil For Packaging Applications:

Food packaging: 1235 aluminum foil is widely used in food packaging applications, including as pouches, wraps, and lids, to guarantee food safety and freshness.

The most common application for 1235 aluminum foil in the food packaging industry is lamination. Foil may be readily bonded to a range of surfaces using wet or dry lamination processes because of its smooth and flexible surface. Foil film laminates, aluminum-polymer-aluminum composites, and paper-aluminum-paper sandwiches (PAP) are examples of common laminates. In addition to its usefulness as a moisture and grease barrier, the foil layer also adds aesthetic value to pouches, different packaging films, food packaging, home packaging, and other laminated objects. Most of the aluminum foil used for lamination comes from the flexible food and beverage sectors, specifically 12-35.

Pharmaceutical packaging: Because of its outstanding barrier properties, which protect the contents from outside influences, 1235 aluminum foil is a great choice for pharmaceutical blister packs, pouches, and wraps.

Industrial packaging: Items that need to be protected from moisture, chemicals, and environmental factors require 1235 aluminum foil.

1235 aluminum foil is extensively utilized in the packaging industry for lamination and flexible packaging because of its superior protection, adaptability, and sustainability. Innovations in packaging solutions and new uses are practically limitless as long as aluminum foil producers can find innovative ways to create high-quality products. Recognize the exceptional quality of 1235 aluminum foil and observe how it alters flexible packaging and lamination, so altering the direction of the business.

1235 Aluminum Foil Benefits For Flexible Packaging and Laminating

Protection against pathogens, light, moisture, and oxygen: 1235 aluminum foil serves as a robust barrier to preserve the freshness and quality of packed goods.

Heat resistance: 1235 aluminum foil has outstanding heat resistance, making it perfect for flexible packaging and laminating applications that need thermal stability.

1235 aluminum foil strikes a good combination between hardness and flexibility, which makes it easy to mold into a variety of package designs without sacrificing structural integrity.

Sustainability: 1235 aluminum foil satisfies the industry's increasing need for recyclable and ecologically friendly packaging solutions because it is recyclable by nature.

China is a global leader in the production and supply of aluminum foil. Chinese producers of aluminum foil are able to provide aluminum foil rolls at competitive pricing because they have access to a plentiful supply of bauxite and cutting-edge aluminum electrolysis technology. HTMM is a well-known Chinese producer of aluminum foil, and we are a leading supplier to clients all over the world because of our rigorous quality control methods and reliable delivery.

In 2009, our (HTMM) Aluminum was founded. Over the span of more than ten years, it has grown to become one of China's top producers of various aluminum items, both nationally and internationally. Modern technology and the most sophisticated production lines are included in our plant.

To guarantee the stability of the quality of our products, we consistently adhere to international quality standards such as ISO 9001. Our factory will roll, cool, anneal, cool, etc. on the aluminum ingots after receiving the customer's order. Our rolling machine uses both an ABB plate control system and a HONEYWELL thickness control system to guarantee that clients obtain aluminum foil at varying thicknesses during the rolling process.

Additionally, we will use the sampling approach to check the quality of each batch of items given by our clients. Our committed R&D team is committed to delivering personalized services and ongoing product innovation.

Our primary goal in pursuing green operations is sustainability. Aluminum Alloy Foil 1235 For more than ten years, we have been supplying 1235 Alloy, our best-selling commodity, to flexible packaging factories in nations with strict product grading restrictions. Among these countries are South Korea, Germany, Russia, and others.

Furthermore, SVHC, the US, and Europe have granted third-party quality inspection certificates to our (HTMM) 1235 aluminum foil goods. These certifications attest to the fact that our foil satisfies all specifications for food-grade foil and is safe to handle food. It can guarantee that neither the aluminum foil nor the food will be harmful to your health.

In conclusion, 1235 aluminum foil is the foundation of the packaging business, offering flexible packaging and lamination the best possible protection, adaptability, and sustainability.

The potential for new uses and developments in packaging solutions is almost endless, provided that producers of aluminum foil stay creative and provide high-quality goods. Accept the exceptional quality of 1235 Aluminum Foil and observe how it revolutionizes lamination and flexible packaging, ultimately altering the direction of the business.