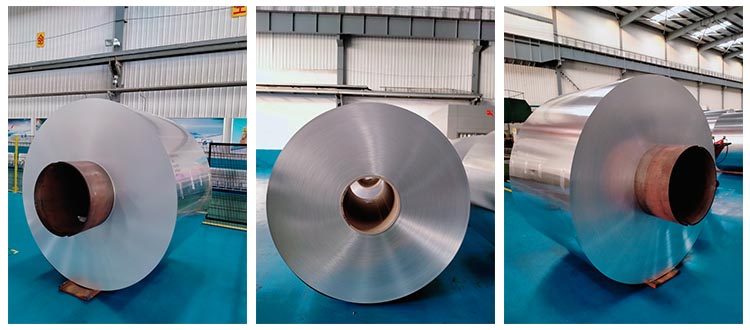

Strict quality control standards are followed in the production of Aluminum Foil 8011. Hardness relative to the +/-1 micron thickness tolerance ensures uniform passage through the fabrication machine. The soft O temper retains flexibility without cracking during aggressive forming techniques. Surfaces are meticulously cleaned and treated to the low emissivity specifications preferred by the HVAC industry. Regional data and just-in-time delivery scheduling further support the manufacturing process at the right time. Compliance documents and special packaging protect high-performance foil along the supply chain.

Leading manufacturers collaborate extensively with major HVAC OEMs to develop new applications and solutions. The customized composite laminates combine 8011 foil with other materials like hard plastics for hybrid convenience. Pilot programs evaluate cutting-edge innovations to improve sustainability, such as using more post-consumer recycled materials or applying renewable energy processes. Included feedback moves the entire enterprise towards efficiency and environmental goals. Overall, premium 8011 aluminum foil remains the solution of choice for HVAC manufacturers seeking optimized performance, durability and protective barrier characteristics for airflow distribution systems.

In addition to ducting systems, Aluminum Foil 8011 finds applications in a variety of other HVAC components and installations. Its formability makes it suitable for building complex air terminals, grills, registers and diffusers that efficiently guide conditioned air into commercial buildings. The factory coating with low-smoke, zero-halogen composition achieves the important fire safety certification of 8011 products for installation in plenum spaces. Perforation lines can be added through automated processes to control airflow with balance and control.

When properly installed by licensed professionals, 8011 Aluminum Foil For flexible duct are engineered to last for decades with minimal maintenance needs. Periodic inspections look for any damage caused by water intrusion or accidental puncture. Simple patch repairs involve pressing the replacement foil sections into place. Joint sealing compounds may need reapplication about every 10-15 years as they naturally dry out with prolonged use. Manufacturers offer service warranties and ongoing maintenance contracts to preserve optimal performance.

In special applications, 8011 foil proves to be essential for humidity control and temperature control in industrial environments such as food production facilities, clean rooms, and medical equipment warehouses. Its barrier properties isolate sensitive spaces from outdoor conditions when incorporated into control air distribution systems. 8011 Aluminum Foil For flexible duct withstands cleaning with harsh chemical sanitizers required in such environments, maintaining integrity through aggressive washes. Accelerated aging tests simulate decades of real-world exposure with no degradation, reinforcing the 8011 as a reliable solution wherever climate control is mission critical.

Suppliers leverage the latest Industry 4.0 technology to ensure 8011 foil delivers consistently optimized performance. Real-time data monitoring of slitting, rolling and batch annealing furnaces maintains accurate 8 micron gauges. The auto-steering coil transports the foil rolls directly from cleaning to packaging and avoids human contact with the risk of contamination. Digital networks integrate manufacturing with quality control labs, enabling immediate product nonconformity response from suppliers to customer production lines.

Regional support centers increase the supply of premium products. Local metallurgical engineers consult directly with the fabricator to analyze the constituent challenges. Technical experts troubleshoot in-field issues and validate proposed design changes. The training program transfers expertise in efficient assembly techniques. Exhibits showcase the latest laminating adhesives, smoothing compounds and edge treatments that improve manufacturability.

Collaborative applied science leads to further advances. The joint research validates emerging coating trends to reinforce barriers without the use of PVDC. Pilot production lines test the new 8011 alloy combining enhanced corrosion resistance with equal formability. studies that model foil recycling flows combined with other HVAC scrap to maximize circular material flows. The partnership fosters an open innovation spirit to the benefit of the industry.

In addition to its use in Aluminum Foil 8011 For HVAC, 8011 aluminum foil is increasingly used in construction applications requiring weatherproofing and barrier protection. 8011 foil sheeting provides an impermeable waterproofing layer ideally suited for roof underlayment and air barrier installations. It withstands demanding temperature fluctuations without degradation, protecting building enclosures through extended life cycles.

Premium manufacturers take strict precautions in the production of 8011 foil to ensure consistency for such critical end uses. All raw materials are sourced using blockchain technology with full batch traceability, allowing customers to validate purity and compliance. The molecular structure is deliberately engineered through multi-stage processing to achieve the correct rigidity without sacrificing functionality. Quality inspection uses AI-enhanced microscopy by checking integrity down to the micron scale.

As building codes adopt high energy efficiency and sustainability mandates, Aluminum Foil 8011 For HVAC enables compliance through innovations such as active rooftop gardens. Composite laminates that combine the foil with the growing medium allow the roof surface to be partially insulated with plants while still providing a flawless moisture and root barrier underneath. Pilot projects also explore laminated foil to rigid bio-based insulation materials. Ongoing product development positions aluminum as a key component of tomorrow’s smart, resilient structures.

The precision engineering of the physical properties of 8011 aluminum foil and its precision manufacturing lay the foundation for performance reliability across a variety of construction applications. Whether insulating building envelopes or cultivating rooftop gardens, this versatile material plays an increasingly important role through stringent quality standards that meet the stringent demands of the built environment.

In addition to its use in building construction and HVAC systems, 8011 aluminum foil is also commonly used in the packaging industry. Its smooth and flexible properties make it well suited for applications such as foil coatings for food containers and pharmaceutical packaging. The ultra-thin 8 micron gauge provides an effective moisture and gas barrier while maintaining flexibility due to the complex shape.

Leading foil producers implement the strictest quality management practices to ensure 8011 products intended for direct food contact meet regulatory requirements. Raw aluminum ingots undergo rigorous testing to verify that they are free of any heavy metals or other contaminants. The rolling process is carefully controlled to eliminate defects, and each coil is tested multiple times during manufacture. Avant-garde inspection technologies such as digital holography replace traditional microscopy by detecting even subtle variations. Finally, rigorous validation protocols model contamination risks from the packaging liner to the warehouse storage environment.

The premium barrier properties of 8011 aluminum foil stem from its exceptionally high purity achieved through refined manufacturing techniques. Whether used as a blister pack liner, food tray cover or supplementary pouch material, their ability to repel moisture and gas allows products to maintain integrity on shelves or in transit. As packaging sustainability and food safety standards increase around the world, 8011 foil remains an essential component through its unmatched combination of safety and consistency from trusted suppliers.