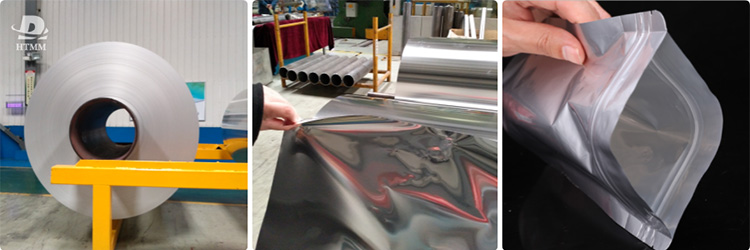

Rigorous testing demonstrates that Aluminum Foil 6.35 micron maintains low gas permeability intact at sub-zero temperatures or after months of storage. This keeps frozen waffle steaks, ready meals and pizza pockets fresher longer. Its soft temper allows complex shapes like pillow packs to be formed easily. Field tests have shown that it withstands industrial freezing and thawing cycles without damage. Converters tailor coating characteristics to balance slip, bonding and burst energy specific to customer packaging needs and processing parameters. Regional technical experts collaborate to ensure optimal results.

Like all aluminum foil grades, Aluminum Foil 6.35 micron is subject to strict quality protocols. Certifications including ISO 9001 and FSSC 22000 demonstrate stringent controls and validated food safety practices. Sourcing and recycling policies maintain a high average recycled material percentage. The facilities use renewable energy and emissions tracking proves annual reductions. These proven sustainability accomplishments support the goals of leading brands while the 6.35 micron foil protects product quality from factory to freezer aisle. The unparalleled freezer-friendly barrier and formability makes it an integral part of the global frozen and chilled food supply chain.

Thin Aluminum Foil 6.35 micron gauges promote greater throughput in the packaging line. Its flexibility allows for faster line speeds when filling delicate or irregular products such as pie crusts or biscuits that risk damage. The pilot checks fine-tune processing parameters to maximize uptime. Regional technical support is ready with troubleshooting expertise to optimize film delivery, tracking, sealing and cutting. Precise slit width minimizes waste; Tight gauges ensure consistent barriers across each roll. Process upgrades such as new sealing jaws preserve seal quality for bag changes.

As sustainability commitments increase, Soft Aluminum Foil 1235 For Flexible Packaging takes the lead. The post-consumer recycled ratio increases through innovation and also matches the required characteristics. Multiple de-inking and cleaning stages restore the aluminum to nearly its original purity. Feedback from brand partners drives industry-wide recycling technologies even further. Internally, zero waste certification validates wastewater treatment; Using renewable electricity offsets all the carbon. Even outer carton plastic is changed to paper based. These ongoing improvements stem from collaborative R&D and a long-term circular vision shared between suppliers and packaged food players.

Looking ahead, lighter weight mono-materials hold appeal. The 6.35 micron foil actively engages through running barrier-resin laminate tests. Compatible adhesive and resin systems prove comparable safety and formability when preparing hybrid structures for polyethylene recycling flows. Similarly,Soft Aluminum Foil 1235 For Flexible Packaging can clean and fully assemble in compostable solution during development. As ever, it works with customers to boldly align business needs with environmental priorities to pioneer solutions — ensuring barrier packaging sustainably supports global food supply chains far into the future.

When it comes to frozen food packaging, seal integrity is non-negotiable. The 6.35 micron aluminum soft foil provides a very reliable and strong seal through high speed form fill seal operation. Its consistent gauge and optimized heat seal surface provide uniform bonding critical for withstanding frozen storage conditions. subjects the specimen seals to charge pressure in lab tests and simulates the effect of distribution without failure. Field testing demonstrates that seals remain completely intact from factory freezing through distribution, retail display freezers and home use.

Resource efficiency increases as the transformation process proceeds. The narrow width tolerance of the soft foil combined with the automatic slitter and rewinder realizes dramatic waste reduction. Near-infrared sensors integrated into the seal inspection immediately detect any seal problems before the packaging reaches them. Data analysis, meanwhile, reveals opportunities for optimization along lines such as reducing transition times between jobs or adjusting seal temperatures based on environmental conditions.

Partnerships extend beyond productivity improvements. Aluminium Foil Rolls 6.35 Micron 1235 Alloy collaborates closely with major frozen food brands in setting sustainability goals, developing recycled-material conversion pathways and diversifying product sourcing through qualified post-consumer pools. Joint advocacy strengthens curbside recycling programs that enhance aluminum recovery by educating policymakers.

The value of the Soft Aluminum Foil 1235 For Flexible Packaging lies in its versatile shelf life protection, which protects countless frozen foods enjoyed worldwide. To further strengthen this performance, R&D engineers are pioneering enhanced EVOH barrier enhancements. Laboratory tests demonstrated that ultrathin lamination with EVOH resin dramatically reduced the rate of oxygen transmission compared to bare aluminum. Commercial packaging tests then test long periods of antioxidant storage courtesy of very low headspace oxygen levels within pillow packs and pouches. This optimization allows manufacturers a longer processing/distribution window before the risk of product discoloration.

Capacity expansion continues apace to maximize the benefits Aluminium Foil Rolls 6.35 Micron 1235 Alloy offers globally. A recently launched manufacturing facility in Southeast Asia triples local production to meet rapidly growing regional demand from food, pastry and poultry producers. State-of-the-art pollution controls reduce emissions beyond all permit requirements. Meanwhile, a significant portion of the energy is derived from on-site solar arrays and hydroelectric sources. This type of investment supports sustainable operations that align with consumer goals while ensuring the hundreds of new direct jobs created boost the local economy.

End-to-end sustainability leadership also maintains its focus on continuous improvement. The new product development pipeline evaluates new substrate materials from industry-based or recovered waste streams as potential replacements for traditional plastic carrier webs or release liners. Initial tests have shown encouraging results indicating that there is no need to compromise the protective properties of soft foils cherished by major multinational packaged food companies. Collaboration across industries will maximize circularity opportunities and help lead a global shift towards nature-positive packaging. The partnership’s legacy of aluminum soft foil helps translate ambitious visions into tangible steps forward.

Aluminum Soft Aluminium Foil Rolls 6.35 Micron, a leader in sustainable innovation, recently launched the industry’s first one-component composition that combines multiple components into a single recycled film. By internally laminating a paper layer, the new hybrid construction captures the unmatched barrier of aluminum with the advantages of recyclability offered by fiber-based substrates. Pilot programs demonstrated its compatibility with mainstream paper and board recycling infrastructure without issue. Recyclers and MRFs reported fiber contamination to be in an acceptable range for new product production. This alignment with the broader waste stream enables manufacturers to more easily achieve circular packaging goals.

Discussions continue across the value chain to optimize the potential for such improvements. Brand owners provide important insights for future refinement based on packaging testing, consumer testing or evolving policy requirements. Municipal groups share information to guide improvements that support smooth reprocessing. Meanwhile, Aluminium Foil Rolls 6.35 Micron technical centers characterize the recycled materials and perform extensive analysis to ensure that the strong barrier properties remain intact through multiple recycling loops. Only through perseverance as an engaged and solution-focused stakeholder can such groundbreaking developments maximize their circular impact in the long term and serve as a model that inspires wider adoption.