To understand its value, you have to decode the technical meaning behind its name. 12 micrometers (12mic) is a precise scale. One micrometer is one millionth of a meter, or 0.001 millimeters. The thickness of 12 microns is one-sixth the diameter of a human hair. This ultimate thinness gives aluminum foils unparalleled flexibility and economy. Despite its light weight, it is a laminate that adheres to other materials and has a strong, light packaging structure that significantly reduces transportation costs and raw material consumption. However, ensuring that such a thin scale has no pinholes, no cracks and uniform thickness is a challenge to the limits of the production process and the basis for high barrier properties.

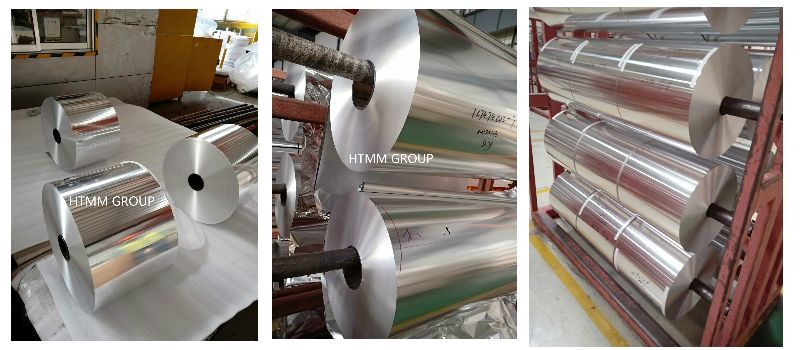

Not all aluminum materials are suitable for such thin packaging foils. 8079 is an aluminum alloy plate developed specifically for the packaging field, whose core advantage lies in component optimization. It is based on pure aluminum and precisely adds elements such as iron (Fe) and silicon (Si). This ratio brings about three important characteristics: the addition of iron to form a fine intermetallic compound, which can significantly improve the mechanical strength of aluminum foil, making it difficult to break in the high-speed packaging machine, and ensuring production efficiency. 8079 alloy has excellent tensile performance and can be rolled stably to a thickness of 12 micrometers or less without loss of integrity. Precise component control and advanced rolling process ensure smooth and shiny foil surfaces and minimize micro pinholes that can cause poor packaging.

| Alloy/temper | 8079 / O |

| Thickness | 12 micron ( 0.012mm) |

| Width | 200mm-1850mm |

Ho means "Hard Oven", that is, antipyretic treatment at high temperature. This is an important step in determining the final performance of aluminum foil. As the aluminum foil is completely re-fired, the internal lattice structure is uniform and stable, and internal stress generated in the rolling process is eliminated. This makes aluminum foil very flexible and tenacious and can withstand repeated crumbs without bursting. It is particularly suitable for pasty, pasty product packages (toothpaste, ointment, etc.) and irregular shaped candy packages.

The 12um 8079 aluminum foil itself has excellent barrier performance, but it is easy to tear, wrinkle, and cannot be heat sealed independently. The core process of Lamination, called "gold combination", is used in combination with plastics (such as PE, PP, PET) and paper to complement their functions. And realize it.

Typical laminate structures are typically BOPP or PET, which provide excellent print compatibility, wear resistance, and mechanical strength with brand patterns that attract consumers. The middle layer is the core of the barrier. It is like a solid wall that blocks 100% of the intrusion of oxygen, water vapor, light, and odors. This fundamentally prevents food degradation due to oxidation, mold due to moisture, flavor loss, and photoreactions, which can dramatically extend the shelf life. The inner layer is generally flow stretched polypropylene (CPP) or polyethylene (PE), these provide excellent thermal sealing performance to ensure that the packaging bag is tightly and quickly sealed, the material itself meets the food contact safety standards, directly Protect the contents. Advanced technologies such as dry laminates and solvent-free laminates combine these three (or more) layers tightly together to incorporate the processability and printability of plastics, the upholstery of paper, and the overwhelming barrier of aluminum foil. +1+1>3 ".

This 12 micrometer 8079 aluminum foil barrier material has permeated almost every corner of our daily lives. Used in snack nuts, it blocks out oxygen and moisture to preserve the crunchy flavor and peanut aroma of potato chips. Highly moisture-resistant protective milk powder, coffee powder does not solidify and keeps the flavor of the seasoning. It provides the highest level of protection for chemicals and vitamins that are sensitive to light, oxygen and moisture, and is directly linked to the safety and effectiveness of drugs. Pet food and liquid soup packs extend shelf life and facilitate storage and use. The specially designed composite bag of aluminum plastic can be used for food packaging, meat packaging, can withstand the high temperature sterilization above 121 degrees Celsius, and realize the convenience of long-term storage at room temperature. It is also used for packaging chemical raw materials sensitive to moisture and Japanese products.

8079 aluminum foil this layer of 12 micrometers is the crystallization of raw materials, as well as the wisdom of material science, metallurgy technology and package design. Behind its ultimate thinness and softness is a solemn commitment to product quality, protecting the consumer's heart to health, as well as a deep pursuit of resource efficiency and sustainable development. It quietly exists in hundreds of millions of packaging, inconspicuous, but ensures the indispensable invisible hero of commodity value and security in the world supply chain.