Advantage Of 3003 H24 Grade Aluminum Foil Jumbo Rolls

3003 H24 Aluminum Foil Rolls Jumbo For Food Container is often chosen for large format jumbo rolls due to its strength, formability and durability, making it well suited for food containers and packaging applications. The 3003 designation refers to an alloy mixture of aluminum, manganese, and magnesium, with increased corrosion resistance compared to ordinary aluminum. The H24 temper means that it undergoes work hardening during machining to an intermediate strength state, creating an optimally hard yet flexible material.

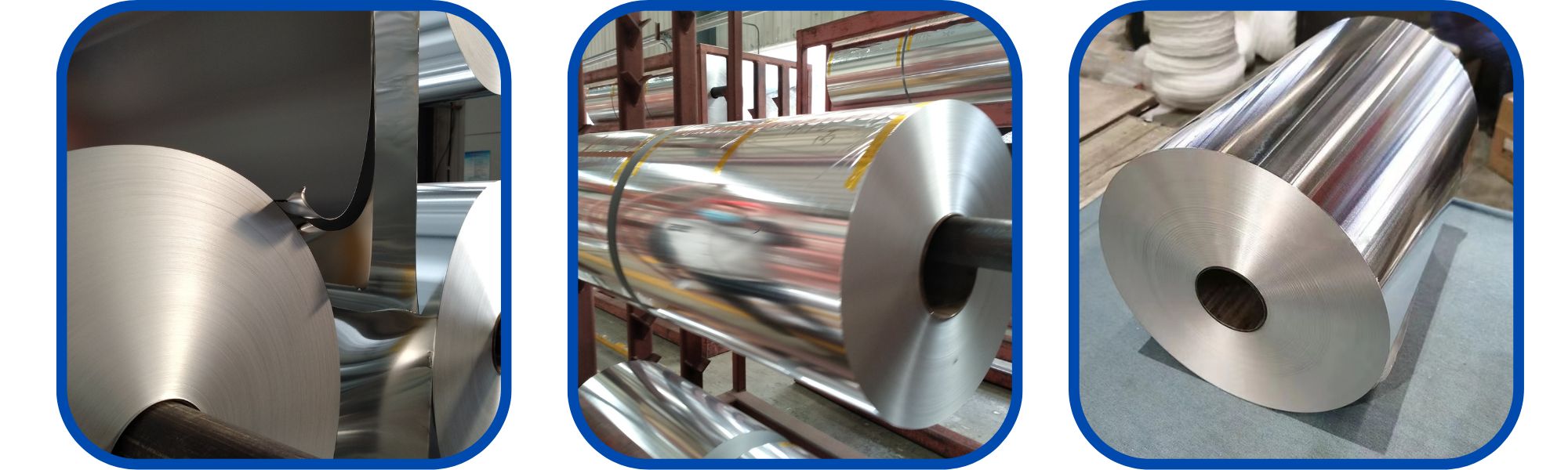

On an industrial scale, the benefits of 3003 H24 Aluminum Foil shine through jumbo roll packaging. For food service manufacturers, ream widths up to 12 feet wide increase square footage efficiency. Smooth, wrinkle-free surfaces work flawlessly on high-speed machines. Its dead-folding properties enable folding with crisp edges without cracking. 3003 H24 Aluminum Foil makes high-performance barrier wraps and containers in combination with treatments such as non-stick coatings.

Careful quality control ensures consistency of food quality. Certifications under ISO 9001 confirm consistency. Patented electrolysis manufacturing techniques developed with university partners eliminate impurities to gain FDA compliance for direct contact use. Rigorous testing simulates real-life conditions from freezer storage to steam table storage and confirms that no degradation occurs.

The 3003 H24 batch format also improves durability. Giant reels minimize upstream and downstream packaging waste. The rolled scrap is recovered on site for reuse. The partnerships are developing technologies to increase recycled content, reducing carbon footprint long-term. Using renewable energy offsets greenhouse gas emissions.

From commercial and online grocery fulfillment to large-scale meal assembly, foodservice relies on the versatility and efficiency of the 3003 H24 Aluminum Foil to increase productivity while maintaining food safety standards. Their performance responsibly supports global nutrition.

Quality and consistency are key to the food industry and 3003 H24 Alu foil is an ideal choice. Its alloy composition is strictly controlled to exact tolerances during electrolytic melting. Properties such as flexural flexibility and dead layer are measured through routine laboratory simulations. The foil undergoes rigorous chemical and structural analysis, and testing is extended to new applications. This provides protective capabilities in a variety of storage and distribution conditions. In addition, automated 100% inspection uses artificial intelligence to detect even microscopic defects, further enhancing its food safety reputation. 3003 H24 Aluminum Foil suppliers' dedicated research laboratories are constantly developing materials science to meet evolving regulations.

Sustainability is a key factor for brand owners and consumers. The leading 3003 H24 manufacturer powers all operations using renewable energy, minimizing its carbon footprint. Their smelters undergo energy audits to continuously improve efficiency. Foil scraps are reused internally whenever possible, while useless trim is recycled for other applications. Factories use lean manufacturing principles to eliminate waste. The source prefers partners that maintain certifications such as ASI and SA8000, which cover social and environmental impacts. The jumbo rolls themselves contribute – their surroundings mean optimized trucks and less packaging material per square foot produced. All activities use LCAs to transparently measure and progressively reduce their life cycle impacts.

Partnership accelerates beneficial sustainable progress. Cooperative applied research platforms fuel innovation to improve performance, food safety and sustainability. Academic communities inspire the next generation of scientists and engineers. Open innovation helps solve supply chain challenges, whether through new materials or digital efficiencies. Cross-industry knowledge sharing accelerates solutions to common global problems. Commitment to multilateral initiatives keeps industry influences constructive. Together, these joint initiatives future-proof the capabilities of Aluminum Foil Rolls Jumbo For Food Container, providing global access to nutritious, affordable packaged foods for decades to come.

New product development maximizes the attributes of 3003 H24 aluminum foil to meet evolving market needs. Prototyping explores marrying foil with oxygen scavenging materials or antibacterial coatings to extend shelf life without preservatives. Digital printing on foil surfaces allows personalized nutrition facts or unique branding/identification of prepared foods. Photoluminescent inks may one day show ideal consumption windows. Biomimetic foil designs take cues from structures such as rose petals or dragonfly wings to improve properties such as oil resistance. The test verifies the functionality scores of prototypes favorably against alternatives on sustainability metrics. Product management ensures that designs facilitate recycling sorting technologies.

3003 Aluminum Foil suppliers apply the strictest sustainability practices. Smelting is undergoing improvements to achieve net zero emissions through carbon capture use and storage. Community benefits accompany locally sourced renewable energy installations. Zero-waste-in-place programs advocate for materials that are difficult to recycle. A public report discloses annual goals and progress that has been publicly verified by third parties. Employees receive health support and skills training for professional development. Strategic sourcing helps marginalized artisans through fair supply of raw materials. Community outreach programs foster circular social enterprise incubation. Corporate governance embraces diversity for informed decision-making while respecting all cultures.

Future cooperation will be crucial to overcome challenges together. To maximize shared learning, Aluminum Foil Rolls Jumbo For Food Container manufacturers bring together stakeholders from innovators to waste management planners. Collaborative planning strengthens recycling infrastructure to fully close material loops to vulnerable communities. University partnerships drive curriculum that advances applied sustainability sciences. Pre-competitive coordination increases industry-wide adoption of recycled content. The development of clean production techniques on a global scale protects our common natural resources for future generations. Through open-minded collaboration, 3003 H24 aluminum foil will reliably meet humanity's nutritional needs in a sustainable manner for our collective future.

3003 H24 Aluminum Foil Raw Materials For making Food Container

Emerging technologies continue to expand the capabilities of 3003 Aluminum Foil Rolls Jumbo For Food Container. The study investigates the incorporation of antimicrobial nanoparticles into coatings to enhance product safety without chemical additives. Embedded RFID tags or encrypted watermarks could one day authenticate high-value shipments or quickly retrieve bulk data. Bioplastics and nanocellulose composites hold promise for integration with aluminum for lighter, compostable packaging. New alloys in development could increase the strength-to-weight ratio, allowing less material to be used while maintaining performance. Simulation and modeling optimize material yield from these innovations to minimize environmental impact. Pilot programs test game-changing ideas with the most sustainable advances destined for commercialization.

Strategic partnerships make it easier for 3003 H24 aluminum foil to meet societal goals. Supply chain mapping of partners aims to future proof against geopolitical risks. Worldwide, joint ventures are modernizing aging infrastructure by improving communities' access to recycling. Investments support women in science, fostering diversity that fosters out-of-the-box solutions. Climate change mitigation initiatives combine aluminum's circular attributes with renewable microgrids to foster low-carbon growth globally. Cross-industry harmonization programs create fair trade and responsible sourcing standards that suppliers around the world can confidently achieve. Joint efforts maximize aluminum's role in a shared green, fair future.

Good governance ensures sustainable progress. Advisory boards provide transparent oversight that validates sustainability goals and reports. Systematic due diligence verifies that suppliers protect human rights. Ethics ombudsmen investigate stakeholder concerns promptly and objectively. Executives link performance to ESG benchmark achievement, prioritizing long-term value. Multilateral assurance statements check the reliability of each annual report. 3003 Aluminum Foil Rolls Jumbo For Food Container will reliably serve global food needs sustainably through accountable management and inclusive collaboration.