Customizable containers enable versatile applications. Making mini pie crusts facilitates filling testing. Foil pan part snacks perfectly for lunchboxes or catering. DIY bento boxes host cute enough meals for Instagram. Slices of pie or cupcakes are attractively served in foil containers for events. Food preservation entrepreneurs package creations attractively on a mass scale. Creative chefs form the right vessel for concocting nuevos. In this way, Jumbo Roll learns entrepreneurship and hands-on learning through container prototyping.

Centuries of proven food safety recommend aluminum in contact with consumables. Whether in the fridge, oven or microwave, oxygen and moisture barriers maintain freshness. The tests verify that no chemical changes occur from heat exposure to the foil. Its hygiene and affordability offset the cost when compared to other products. Sustainable too - the foil recycling program diverts used versions out of landfills. As the population demands a change in worldwide distribution, bulk foil formats efficiently streamline global packaging.

Innovators explore pushing boundaries. Laser cutters intricately transform single foil sheets. New alloys and coatings under development may soon provide containers with non-stick superstrength or self-sterilizing capabilities. Technology naturally extends shelf life without worrying about preservatives. Digital printing brings visuals to life with customized nutritional information, branding or language. Creative minds apply design thinking by connecting communities through purpose-filled nourishment.

Clearly, the flexibility, food compatibility and sustainability of aluminum foil raw materials make jumbo rolls ideal for designing versatile, handmade or mass produced packaging that will nourish citizens around the world for years to come.

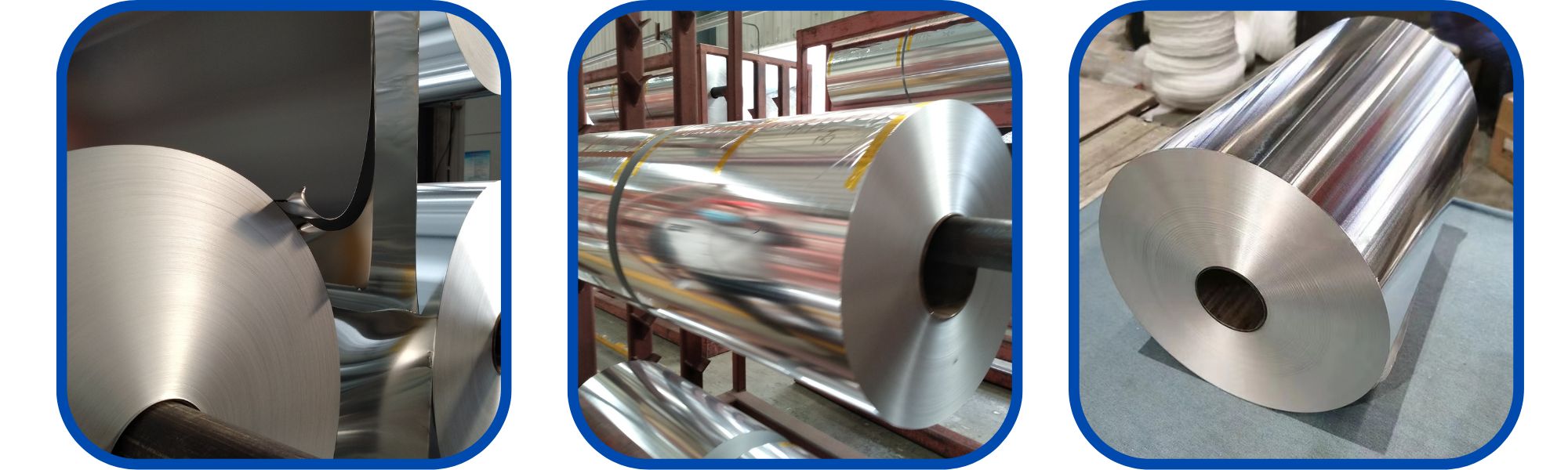

The large format of jumbo aluminum foil rolls makes them very economical for businesses producing Aluminum Foil Raw Material For Making Food Container at scale. Their width of up to 12 feet means less time is spent flipping and setting up the product, speeding up production. The very long length also reduces how often rolls need to be changed which reduces downtime. Consistent thickness and surface characteristics across large reels ensure a uniform end product batch to batch. The large surface area of the roll creates minimal waste when trimming and cutting critical sections.

Using jumbo rolls also has sustainability benefits. Less packaging material is required per square foot of foil produced. Their circumference allows truckload optimization for transportation efficiency. Any scrap generated can be collected and recycled back into new products. Many commercial roll suppliers have sustainability programs such as using renewable energy and prioritizing recyclability in container design. Some partner with organizations in initiatives such as community cleanups and education.

New forming techniques are constantly emerging in design. Thermal forming provides infinite shapes for moldable properties up to 500 degrees Fahrenheit. Deep draw vessels are perfectly vacuum forming molds. When combined with laser cutting or CNC machines, complex designs are facilitated. Printing technologies such as digital, flexo and hot stamp rendering customize graphics and text high resolution on foil. Prototyping constraints with different mix tests or increases energy capacity.

From bespoke bento boxes to mass-produced takeout trays, the applications of Aluminum Foil Raw Material For Making Food Container are limited only by imagination. Culinary schools use it as an educational medium for pot innovation projects. Pop-up foodstalls debut seasonal menus served in a sustainable manner. Corporates launch new brand attendants with on-brand packaging. Makerspaces invite community workshops that foster creativity that lead to entrepreneurial ventures.

Clearly, the versatility and economics of large-format aluminum foil continue to expand opportunities to serve global nutritional needs conveniently, affordably, and with low environmental impact. With ongoing technical advances, the possibilities are limitless.

Advanced manufacturing techniques are pushing the envelope of functional container design from jumbo aluminum foil rolls. 3D printing polymers allows the production of thin, durable molds to heat form complex shapes with deep draws not otherwise possible. New alloys with increased formability open up opportunities such as complex embossing or integrated handle structures. Coatings offering new properties reach pilot testing, such as barriers against grease/moisture or autoclaved surfaces for food trucks. Customer prototyping programs test real-world functionality and sustainability. Partnerships accelerate innovation in commercialization, benefiting global access to nutritious on-the-go options.

Sustainable practices ensure 3003 Aluminum Foil Raw Material For Making Food Container nourish communities responsibly. Source favors stakeholders who protect human/indigenous rights and biodiversity. Zero-waste solid-recyclable scrap champion for other applications. Renewable energy energy in all smelters with carbon reduction validation. Closed-loop infrastructure expands modernized urban/peri-urban recycling worldwide. Analytics shape strategic sourcing and processing to minimize cumulative impact. Certificates such as conflict-free mining reinforce conformity. Multi-stakeholder initiatives build standards that enable globally coordinated progress.

Advances in education cultivate informed views that value the role of aluminum. The curriculum incorporates practical skills and sustainability science. Makerspaces foster young people’s exploration of container engineering. The displays show the utility of protecting content and planetary health through an infinite recycling advanced collection program. Accreditation reinforces municipal commitment to ecosystem recycling. Spread understanding of the closed-loop economy, strengthening aluminum capabilities to ensure global access to sustainably nutritious packaged food.

With ongoing innovation, best practices and collaboration, multi-purpose 8011 Aluminum Foil Raw Material For Making Food Container made from jumbo foil rolls will reliably nourish the citizens of the world for generations to come.

Promoting education inspires the next generation of problem solvers. The school curriculum introduces the principles of design, engineering and circular economy through hands-on container crafting. University incubators support student entrepreneurs by leveraging 8011 Aluminum Foil Raw Material For Making Food Container to address unmet needs. Interactive science centers showcase the properties of aluminum and demonstrate careers in advanced manufacturing. Brings greater visibility for advocacy champions who strengthen municipal recycling rates through community organizing. Together, these efforts foster an informed public that values aluminum’s role in closing the material loops to sustainably nourish humanity.