3003 Aluminum foil containers can withstand the temperature changes well, at -20 ° C-250 ° C high and low temperature, the molecular structure is stable does not change. Its use temperature can be from freezing to extreme baking and barbecuing, during which the foil is not deformed, does not rupture, does not melt or scorch, and does not produce harmful substances.

Although the aluminum foil is very thin, but the barrier is strong, can completely block the light, gas and other substances, improve the degree of preservation and protection of moisture, and to prevent the leakage or mixed taste, can effectively maintain the original flavor and characteristics.

Aluminum foil has a wide range of uses, such as aerospace food packaging, general meat packaging, cable foil and building insulation.

Aluminum foil packaging is used to protect against moisture and to prevent air leakage. It also makes the goods or items look more beautiful, more attractive, enhances the aesthetics and quality of the product's appearance, and plays a vital role in the hygiene and shelf life of the product.

3003 Aluminum foil products manufacturers can according to the needs of food processing enterprises and catering enterprises in the aluminum foil lunch boxes and containers for color printing, surface coating, embossing, embossing.

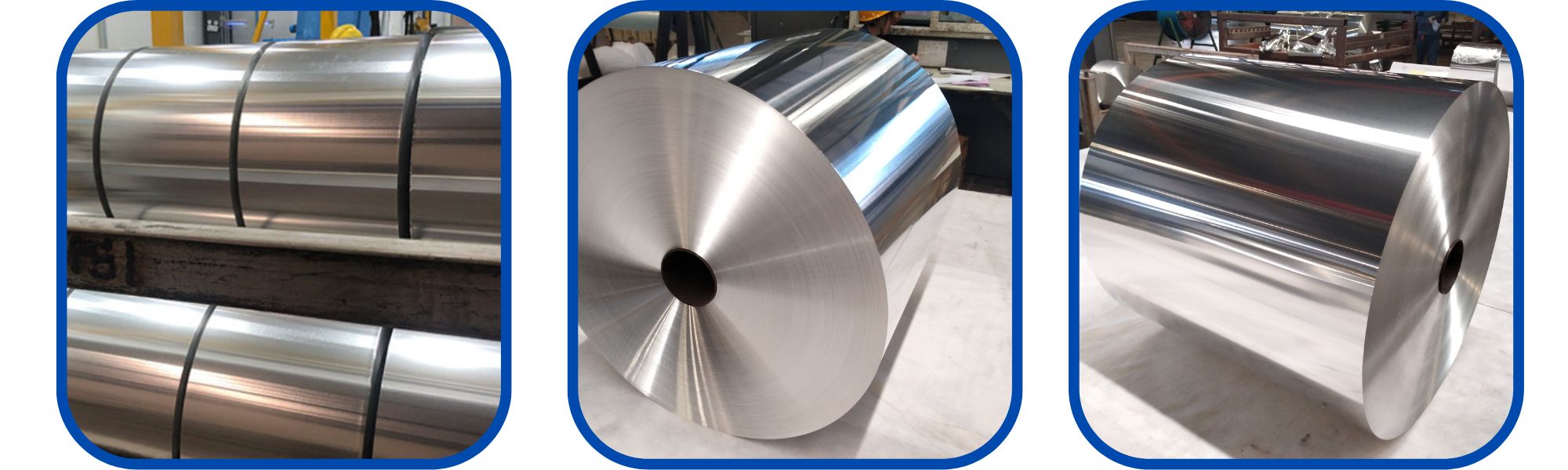

Henan tendeli metallurgical materials Co., Ltd. is a specialized in 3003 aluminum foil processing with the production of companies, the company set up more than 10 years, with rich experience in aluminum foil processing.

Aluminum foil is one of the most versatile materials used for food packaging and storage. It's lightweight and malleable, making it ideal for packaging, baking pan linings and making disposable containers. However, not all aluminum foil is created equal. For applications where high quality is important, such as food service or industrial packaging, choosing the right aluminum grade can make a big difference.

What is 3003 aluminum foil ?

Alloy 3003/H24 refers to the alloy composition and tempering state of aluminum used to make aluminum foil. 3003 indicates that the main alloying element is manganese, with a content of 0.12-0.25%, and the remainder is aluminum. H24 tempering indicates that the aluminum foil has undergone a specific heat treatment process.

Aluminum is naturally soft and malleable. H24 tempering increases the strength of the metal through work hardening. 3003-H24 food containers are made of high-quality aluminum foil sheets that are heated to high temperatures and then stretched through rollers to form ultra-thin aluminum foil gauges. This work results in changes in the molecular structure that impart greater tensile strength without losing ductility.

The main properties of 3003h24 Aluminum Foil

The addition of manganese and H24 tempering give 3003 aluminum foil unique properties that make it the first choice for high-end food packaging applications:

Strength - With a minimum tensile strength of 20kpsi, 3003h24 foil holds its shape firmly and will not wrinkle, crease or tear as easily as softer foils. This maintains integrity during transportation, storage and use.

Formability - Despite its strength, 3003h24 Aluminum foil is still very malleable and can easily be formed into containers, wrapped in large quantities, or sharply curled around the edges without cracking. Suitable for various product sizes and shapes.

Corrosion Resistant - Manganese helps protect aluminum from corrosion from other materials such as food, sauces, moisture or gas that it may come into contact with. 3003 foil Aluminum maintains a bright, attractive appearance better than regular foil.

Heat Transfer - As an excellent heat conductor material, 3003h24 Aluminum foil quickly transfers temperature from the cooking surface to evenly cooked and crispy food. It also helps maintain hot or cold holding temperatures during storage and transportation.

Chemical Resistance – 3003 aluminum foil is highly chemically resistant to chemicals found in foods such as acids, oils and seasonings that can degrade softer grades over time.

Hygienic - 3003h24 aluminum foil has a smooth, non-porous surface that has no bacteria or odor and is easy to clean. It meets FDA requirements for direct food contact applications.