Aluminum Foil Price Per Ton within normal market rates may vary according to specific product characteristics. Thinner gauges below 10 microns increase manufacturing costs and therefore command a premium. Foils destined for premium food packaging may incur higher costs due to higher purity and coating requirements. Imported foils often have higher tariffs which affect the selling price delivered. Domestic orders of bulk reels in excess of 10 tonnes will generally have a lower price per kilogram because of shipping and handling efficiency. Products customized with shape, color or treatment also factor into the final invoiced cost.

While volatility in aluminum products can cause price swings, long-term trends point to foils being priced very competitively relative to alternatives. Its inherent recyclability provides the inherent long-term cost advantage of aluminum over single-use plastics. Major producers also invest heavily in efficiency-driven technologies such as near-zero waste injection furnaces to exert downward pressure on production values. The foil industry’s strong recycling rate stabilizes security of supply against single-source materials. These strengths help maintain the attractiveness of aluminum for value-conscious packaging applications now and in the future.

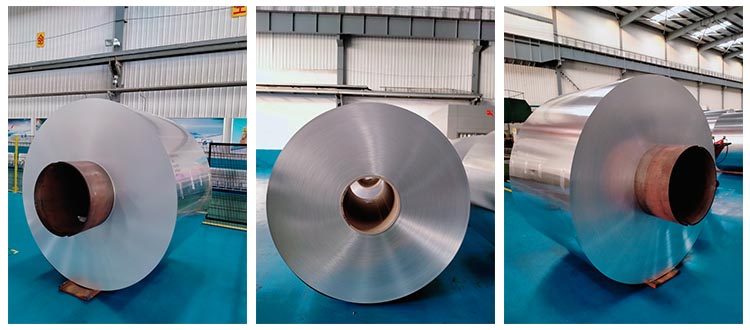

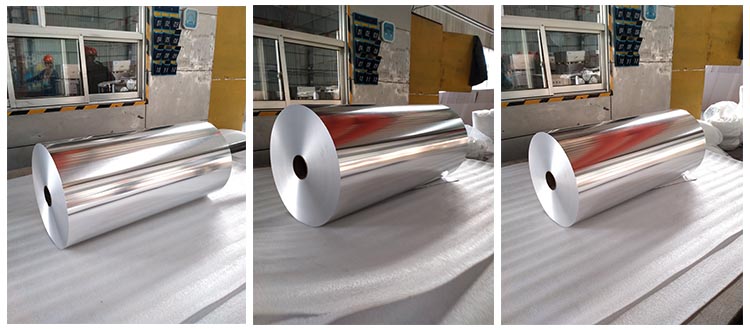

8079 Aluminium Foil Jumbo Roll is one of the most widely used foil blends for flexible packaging applications due to its strength, formability and barrier properties. The foil is produced on specialist rolling lines in ultra-thin jumbo widths in excess of 2000mm, making it ideal for high-speed lamination processes. The smooth surface of the 8079 foil jumbo roll supports excellent print graphics and adhesive adherence during packaging transformation. It provides excellent protection from light, air, moisture, and bacteria - helping to preserve food quality and extend shelf life.

The structure of the 8079 Aluminum Foil Roll 7mic is carefully engineered for recyclability. It can be continuously recycled without any loss of product quality, making it a sustainable choice for packaging. Leading foil producers implement strict responsible sourcing practices in the sourcing and production of primary aluminum. The independent audit also ensures that stringent environmental and social impact standards are met throughout the global supply chain. Smelting is done using clean energy sources to reduce the overall carbon footprint.

Various packaging innovations are now using 8079 foil jumbo rolls. Advanced printing directly onto the roll surface allows for customized, variable content like the best before date without pre-production. Biomimetic nano structures mimic nature’s lightweight barrier for ultra-thin gauges with equal protection. Only in critical areas of food contact does the strategic application of foil further improve product utilization. These advances establish 8079 Aluminum Foil Roll 7mic as a high performance yet environmentally-efficient solution for flexible packaging.

Aluminum foil prices vary depending on a number of market factors but are generally within a consistent range. The primary driver of short-term price fluctuations is the global commodity price of aluminum ingots, from which foils are produced. As the underlying Aluminum foil price per ton rises or falls due to supply and demand factors, so does the price of foil. Other impacts include energy costs for smelting, and macroeconomic conditions affecting producer margins. Of the general parameters, particular foil grades may attract a slight premium due to additional processing requirements.

Over the long term, Aluminum foil price per ton have remained relatively stable compared to alternative barrier materials. This is due to the unique recyclability of aluminum - it does not degrade through repeated recycling cycles. About 75% of all aluminum produced so far is still in active use today through recycling. This circularity ensures a consistent high-quality scrap supply that stabilizes both aluminum ingot production costs and overall market volatility. Manufacturers also invest heavily in efficiency to exert downward pressure on costs over time. Near-zero emissions smelting technology minimizes energy requirements. The move to renewables further enhances long-term pricing sustainability and security.

Looking ahead, the recyclability and versatility of 8079 aluminum foil for flexible packaging is expected to support its competitive price role for packaging. The innovations will optimize usage rates and increase circularity for post-use foils. Even as packaging applications become more specialized, aluminum’s strength and barrier properties ensure it remains well suited to meet more stringent requirements. Its cost profile and light weight capability also aligns well with the pressure to reduce packaging’s environmental footprint. These strengths will help aluminum foil provide high performance solutions at fair market prices in the future.

In addition to internal supply and demand factors, government policies and trade dynamics also influence regional Aluminum foil price. Tariffs on imported foil drive up costs, which are often partially or entirely passed on to buyers. Conversely, policies that support domestic aluminum production through incentives such as energy subsidies can help reduce prices. Bilateral and multilateral trade agreements additionally affect international competitiveness. As aluminum is the world’s dominant commodity, geopolitical tensions occasionally cause temporary price volatility.

At the micro level, Aluminum foil price are determined by several product-specific considerations. Physical characteristics such as thickness, width, and surface treatment affect conversion costs. Very thin gauges below 6 microns 8079 aluminum foil for flexible packaging require more complex instrumentation. A jumbo width of more than 2000 mm allows better economies of scale. Custom features involve additional manufacturing steps. Buyers making large annual purchases in bulk reel quantities benefit from negotiated discounts for logistics efficiency. Pricing is further shaped by unique market dynamics for food and pharmaceutical grade foils where purity and compliance standards require dedicated production lines. Overall, close cooperation between buyers and sellers establishes contracts within the average market range to meet the needs of each party.

Aluminum foil’s versatility and functional advantages, along with its inherently stable long-term cost, ensure its attractiveness now and in the future. Continued innovation and global recycling advances will serve to strengthen these competitive forces and drive sustainability. Through responsible manufacturing and diverse applications, aluminum foil has cemented its important role in packaging and the wider industrial market.