Consumers can trust the reliability and versatility of Alloy 3003 for use in aluminum containers and oiled food containers. They combine all the features necessary to provide consumers with fresh, healthy, and readily available bakery products aluminum foil rolls that meet their demands for quality and value.

Bright reflective 3003 aluminum for food packaging holds up well during processing and distribution. They can be embossed, painted or printed with markings and colors inside and out. commercial aluminum foil roll can withstand the rigors of all types of cooking: broiler, vent and convection ovens, toaster and microwave ovens, and reheating. It is easy to handle, easy to open, easy to use and operate.

According to GB/T 16475-2008 standard, the status of aluminum alloys is indicated by the English capital letter H, and the alloy status code is shown in Table 1.3 2. Add 2 digits (H ) or 3 digits after H (called H ** * ) It can be further subdivided, 1 digit indicates the basic alloy treatment, such as H1 indicates pure strain hardening, H2 indicates strain hardening or incomplete annealing, H3 indicates strain hardening work and stabilization treatment, H3 indicates work hardening and color treatment H4; 2 digits Indicates the degree of strain hardening of the alloy, the fully hardened state is represented by the number 8 and the superhardened state is represented by the number 9. For the state between the fully annealed state (0) and the fully hardened state (H*8 state), please add 1 to 7 digits after H respectively, such as H18 means harder tension machining, H14 means semi-hard machining state, H19 indicates very hard working state.

Container for aluminum foil roll Available in a variety of shapes and sizes, such as fruit tarts, deep apple tarts, individual steak and kidney pies, or large multi-serving desserts. For larger coil containers, additional resistance can be built into the walls of the coil container. By using crimped edges, the rigidity of aluminum coil containers can be greatly increased. In addition, there are special collapsible containers for bakery products, such as cakes, which require a particularly smooth surface when removed from the baking sheet.

The properties of aluminum packaging offer ample scope for packaging regulators looking for a variety of food solutions. Due to the ease of forming and high strength of the 3003 alloy used to make aluminum coil for food packaging, it is available in a variety of standard shapes and sizes, as well as smooth-walled designs.

Aluminum trays can be used for many products, especially ready meals or mixed dairy and fruit desserts. The internal "messy memory" of the aluminum coils used for the containers provides additional opportunities for branding and messaging. Embossed recycling symbols remind shoppers of the value of used aluminum packaging, a benefit that brands can advertise on their eco-friendly packaging.

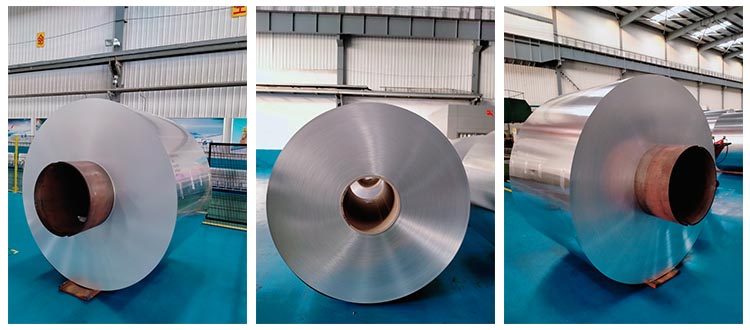

HTMM is aluminum foil roll manufacturers in China.

The use of aluminum foil as a semi-rigid container for food storage has been widely used at home and abroad. With the continuous development of the national economy and the continuous improvement of people's living standards, people's health awareness is also increasing, and people's awareness of environmental protection is also increasing. Aluminum foil has gradually replaced traditional aluminum foam and plastic food boxes.

3003H24 Pre-lubricated Aluminum Foil is generally made from single zero aluminum foil. To make containers of various shapes, container for aluminum foil roll must be formed by stamping and sealing. However, if the aluminum foil has not been treated in any way, the aluminum foil will be scratched due to friction during the sealing process, which will reduce the quality of the product. Therefore, the oil is applied to the surface of the aluminum foil before sealing, and the lubricating effect of the oil can protect the surface of the aluminum foil from impact and improve the quality of the product.

The traditional lubrication method is mainly rolling coating, which is the most primitive lubrication method. Using a roller to lubricate the surface of the foil often results in uneven oil on the surface of the foil, resulting in uneven production during the stamping process. . If the amount of oil is small, the lubrication effect is not obvious, and the aluminum foil will be scratched; if the amount of oil is large, it will cause various problems, such as adhesion between the aluminum foil and the seal.

Inspired by the anti-rust treatment of steel strip surfaces in the rolled steel industry, people began to use electrostatic spraying to spray the surface of aluminum foil. Whether it is imported electrostatic oil or domestic electrostatic oil, the effect is obviously much better than traditional roller oil. The oil is not only applied evenly, but also saves fuel, which is welcomed by customers.