Aluminum foil manufacturing process

Aluminum foil manufacturing process

Aluminum foil rolls have a bright side and a dark side. Many cooks say that when cooking food wrapped or covered with aluminum food foil, the light side should face down, the food should be faced, and the matte side should face up. This is because the bright side is more reflective and therefore reflects more radiant heat than the dark side.

Aluminum foil paper has a shiny side and a dull side. Many people think that which side is used up or down is important. The truth is, it makes no difference at all. The reason why the sides look different is due to the manufacturing process. When the aluminum plate is rolled out, the side in contact with the roller will glow.

The fact is that the shiny side of cooking aluminum foil is only slightly brighter than the matte side. Although some of the extra energy will be reflected by the shiny side, the difference is very small, and there will be no actual difference in cooking. It is inaccurate to say that there is no effect, and cooking the dim side outwards may still be more effective. However, when measured over time at high temperatures, the difference is very small, and the cooking time should hardly change significantly.

HTMM Aluminum foil manufacturing process

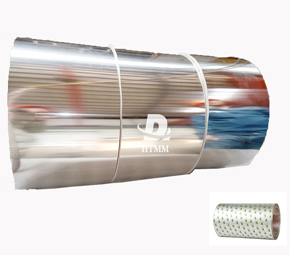

The manufacture of large rolls of aluminum foil is similar to making noodles at home. A large block of almost pure aluminum is rolled several times through a huge steel roller, reducing the thickness of the aluminum block and spreading it out to make it longer. Add lubricant to facilitate operation. Each time the roller is passed continuously, the thickness will decrease. Repeat the process until the foil thickness is reached, and then divide the large plate into the desired width.

This may seem simple, but the actual process can be tricky. For example, when aluminum is rolled out, it becomes hot. If it heats too much, it will stick to the roller, so the roller pressure must be carefully controlled.

Once the aluminum plate reaches a thickness of 5mm, it must be rolled again in the cold rolling stage. First, the aluminum sheet is wound into a roll and then sent to the cold rolling mill for the final stage of milling. It is at this point that the shiny and dim side of aluminum is produced. Since aluminum is now thin, the tension required to feed it into the cold roll can easily break it. So, the sheets have doubled. The side of the aluminum that is in contact with the steel roller becomes more polished and shiny, while the side of the aluminum that is in contact with itself becomes more dull.

HTMM is a leading company in the field of aluminum foil manufacturing. Our Aluminum Foil is exported all over the world. In our research center, our technical engineers develop new technologies to improve the performance of aluminum foil for different purposes. Due to our aluminum foil rolling process, HTMM's aluminum products have different characteristics and sizes. We produce a complete series of aluminum foil for industrial use and packaging, so customers can find a suitable solution according to their thickness and size requirements.