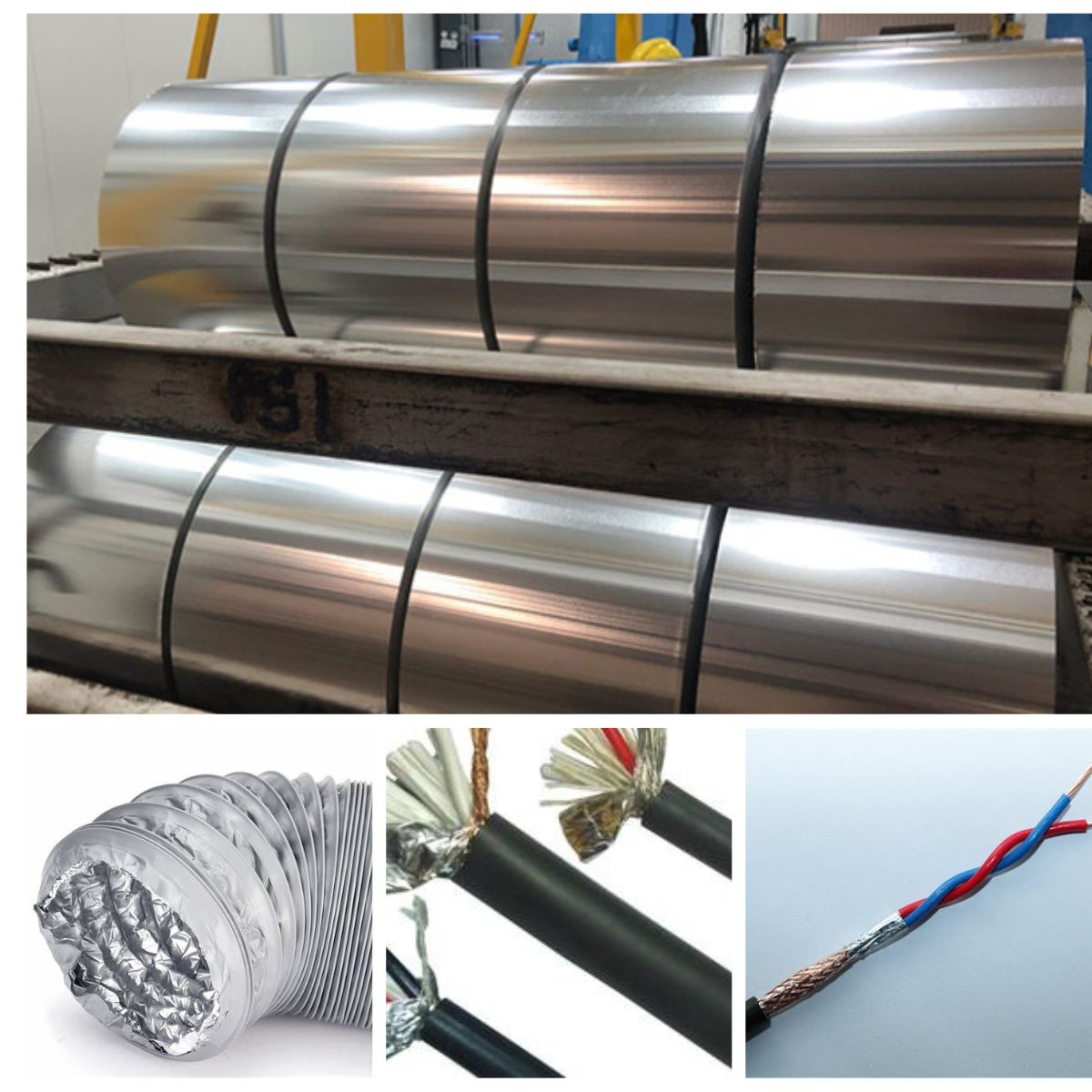

The production process of aluminum foil for industrial cables roughly includes key steps such as raw material selection, rolling, surface treatment and finished product inspection.

HTMM Aluminum Foil factory usually chooses aluminum ingots with higher purity and lower impurity content as raw materials for production. We then carry out the rolling process, where the aluminum ingots are rolled through a rolling mill into aluminum foils of different thicknesses and widths. This is a critical step in aluminum foil production. The rolling process has an important impact on the thickness, width and surface quality of aluminum foil. The workshop master will perform three rolling processes on the aluminum billet. The aluminum billet that has been heated and homogenized must first enter the rough rolling mill for rough rolling, which is one of the key links in alloy foil preparation. Rough rolling is to gradually roll the aluminum billet into the required alloy foil thickness through multi-pass rolling. It also provides good process conditions for the next rolling process. After rough rolling, the alloy foil enters the intermediate rolling mill for intermediate rolling. Intermediate rolling is to further reduce the thickness of the alloy foil through multi-pass roller rolling to form a more uniform foil. After intermediate rolling, further finishing rolling operations are required. Finish rolling is to further reduce the thickness of the alloy foil to the required size through multi-pass roller rolling. Finish rolling requires a more stringent rolling process to ensure the dimensional accuracy and surface quality of the alloy foil. These three processes are the most important part of controlling the thickness of aluminum foil. They are not only more cost investment in the processing process, but also satisfy customers' guarantee of aluminum foil quality. After rolling is completed, the workshop master will perform surface treatment on it. The surface treatment of aluminum foil includes cleaning, lubrication, coating and other processes to improve the corrosion resistance and oxidation resistance of the aluminum foil and ensure the stability of the shielding effect. During the production process, process parameters such as temperature, pressure, and speed are constantly controlled to ensure the quality and performance of aluminum foil for industrial cables. Finally, the finished product is inspected, and the produced aluminum foil is subjected to strict quality inspection, including thickness, width, surface quality, shielding efficiency and other indicators to ensure that the product quality meets relevant standards.

Many customers will ask us what the standards for aluminum foil used in industrial cables are. Different countries and regional organizations have different industry standards. Let me introduce a few commonly used industry standards to you who are reading this.

China's industry standard for aluminum foil for industrial cable shielding is GB/T 31878-2017, which specifies the requirements, test methods, inspection rules, marking, packaging, transportation and storage of aluminum foil for industrial cable shielding; the industry of aluminum foil for industrial cable shielding in the United States The standard is ASTM F2780-2019, which specifies the requirements and test methods for aluminum foil used for cable shielding; the European industry standard for aluminum foil for industrial cables is EN 580-2, which specifies the specifications, performance requirements, and test methods of aluminum foil and inspection rules, etc. These standards have clear regulations and requirements on the material, thickness, surface treatment, shielding efficiency, etc. of aluminum foil for industrial cables. The standards of various countries are basically the same, but there are also some differences in details. In practical applications, consumers still need to choose appropriate products based on their own needs or the standards of their target markets to ensure product quality and performance.

Many customers who come into contact with industrial aluminum foil for the first time are worried about its shielding performance, and some customers have anxiety about shielding properties. In this paragraph, I will tell you about the shielding effectiveness of aluminum foil for industrial cable shielding.

In modern industrial production, cables play a vital role. Electromagnetic interference (EMI) problems have always plagued the stability and security of cable communications. In order to solve this problem, many customers will choose aluminum foil for industrial cable shielding.

The shielding principle of aluminum foil for industrial shielding is that the shielding efficiency of aluminum foil is closely related to its material, thickness, surface treatment and other technical parameters. The main function of aluminum foil for industrial cable shielding is to block and absorb electromagnetic waves, thereby reducing the impact of electromagnetic interference on cable signals. Pure aluminum is an ideal material for making aluminum foil for cable shielding because it has high electromagnetic shielding effectiveness, good electrical conductivity and low density. In addition, aluminum also has good corrosion resistance and oxidation resistance, and can maintain stability in harsh environments. And the thickness of aluminum foil has an important impact on its shielding effectiveness. Generally speaking, the greater the thickness, the higher the shielding effectiveness. But at the same time, too thick aluminum foil will increase the weight and cost of the cable. Therefore, it is crucial for customers to choose the appropriate thickness while ensuring shielding effectiveness.

The advantage of choosing aluminum foil for industrial shielding is that aluminum foil has high electromagnetic shielding efficiency, can effectively block and absorb electromagnetic waves, and reduce the impact of electromagnetic interference on cable communications. Moreover, aluminum foil is also suitable for electromagnetic shielding in various frequency ranges, and can be applied to both high-frequency signals and low-frequency signals. Because aluminum foil has a lower density, it can reduce the weight of the cable while ensuring shielding effectiveness.

In industrial production, cables are an indispensable transmission tool. However, environmental factors and time factors may cause damage to the cables, thus affecting their performance. Therefore, many customers are worried about the durability of industrial aluminum foil.

Because aluminum foil itself has good strength and toughness, it can withstand a certain degree of mechanical impact. The most important thing is that it has good electrical conductivity, which can quickly transmit and disperse electromagnetic energy in the cable and reduce electromagnetic interference. Aluminum foil itself also has good corrosion resistance and oxidation resistance, which can maintain stability in harsh environments and extend the service life of cables. Therefore, customers can be completely assured of the durability of aluminum foil for industrial shielding.

Moreover, the aluminum foil for industrial cables produced in our factory uses pure aluminum or alloys containing magnesium and manganese as raw materials, which has a high degree of stability. This ensures that the shielding performance of the aluminum foil will not be affected by material changes during long-term use. Moreover, the surface treatment process of the aluminum foil after the rolling process makes it have good corrosion resistance and oxidation resistance, and can maintain stability in various environments, and is especially suitable for cable shielding in harsh environments. Moreover, the aluminum foil material has high strength and toughness and can withstand a certain degree of mechanical impact, extending the service life of the cable.