Because of its exceptional barrier qualities, lightweight nature, and adaptability, aluminum foil has become an essential component for many different sectors. 1235 aluminum foil stands out among the other varieties of aluminum foil, especially when it comes to its single-sided polished shape. The properties, advantages, and uses of 1235 aluminum foil 7 micron, aluminum flexible foil, and flexible packaging foil are thoroughly examined in this article.

A minimum of 99.35% aluminum is included in 1235 aluminum foil, an alloy that belongs to the 1 series category of aluminum alloys. Its exceptional conductivity and formability due to its high purity make it appropriate for a variety of uses.

Because of its high aluminum content, improved conductivity, and ability to reflect heat efficiently, HTMM 1235 alloy aluminum foil is a material of choice for a wide range of applications. Its appearance and usefulness are improved by HTMM's single-side polishing procedure for 1235 alloy aluminum foil, which creates a smooth surface perfect for lamination and printing. Additionally, it has outstanding light, oxygen, and moisture protection qualities, which makes it appropriate for packaging pharmaceuticals and food.

The moisture-proof nature of 7mic thick 1235 aluminum foil makes it a good choice for flexible packaging. Food spoilage and moisture incursion may be successfully avoided with 1235 aluminum foil. Over time, food quality and flavor may deteriorate due to the opacity of aluminum foil, which filters light.

The shelf life of items may be greatly increased by using aluminum foil wrapping, which creates a barrier that keeps out light, moisture, and air. Flexible packaging is one of the primary uses. The food and beverage sector uses aluminum soft foil extensively because of its superior barrier qualities, which help to preserve the goods' quality and freshness. 1235 aluminum foil's moisture and oxygen barrier qualities may successfully keep oxygen and moisture out while halting food spoilage. Because aluminum foil creates a barrier that keeps out light, moisture, and air, it may greatly increase a product's shelf life.

In the food and beverage business, 1235 alloy, 7mic thick aluminum foil is frequently used in laminates, such as foil film laminates, aluminum-polymer-aluminum composites, and paper-aluminum-paper sandwiches (PAP). The foil layer gives the finished laminated product—such as food packaging, home packaging, pouches and other packaging films, and liquid beverages—decorative qualities in addition to an efficient moisture and grease barrier.

Aluminum foil, which is frequently used in pharmaceutical packaging, offers a sanitary and impenetrable barrier for medications, guaranteeing that the product is not tainted before usage. Sensitive medications are shielded from light and moisture by aluminum foil, which prolongs their effectiveness. Dosage guidelines and brand information can be printed on 1235 aluminum foil, adding value to the product's appearance while also conveying crucial information. Tablets and capsules are frequently packaged in blisters using 1235 aluminum foil, which makes dispensing easier and shields the product from the elements. Aluminum foil is also frequently used in powder and granule single-dose pouches to guarantee product convenience and stability.

Excellent 1235 aluminum foil has several uses, particularly in electrical components, flexible packaging, medicines, and insulating materials. Manufacturers across a range of sectors use it for its exceptional barrier qualities, high purity, and adaptability. The need for 1235 aluminum foil is anticipated to increase as companies continue to place a high value on efficiency and sustainability, making it a necessary component for the packaging sector.

7mic thick single-sided polished 1235 aluminum foil is one of the most popular products of HTMM factory. We have been exporting our 7mic thick 1235 alloy aluminum foil to Russia, Germany, South Korea and other countries with high quality requirements for product quality. Our (HTMM) products have third-party quality inspection certificates such as Europe, the United States, and SVHC. These certificates can prove that our aluminum foil can be well contacted with food and our aluminum foil quality fully meets the requirements of good food-grade aluminum foil. It can protect the health of food while protecting the aluminum foil from harming your body.

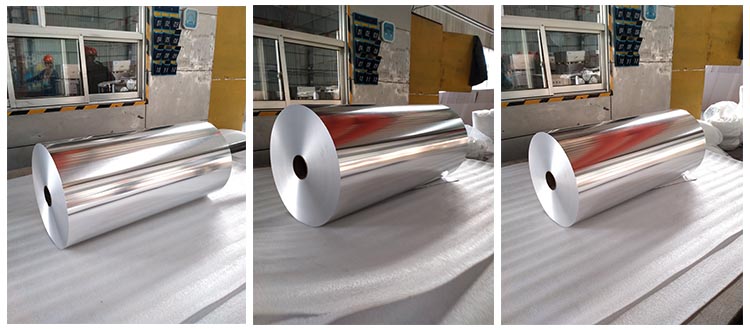

It is processed by processing aluminum raw materials into aluminum billets. Then we will roll the aluminum foil into 7mic with a thickness of 0.23mm through three rolling processes. Then it will be processed using a double-combination machine because the 1235 aluminum foil is polished on one side.

After cutting the aluminum foil to the customer's desired width with a slitting machine, we will return the aluminum foil. We will anneal the aluminum foil in our annealing furnace to get rid of the spots on its surface. Depending on the alloy condition, aluminum foil size, and other variables, the annealing period ranges from 72 to 288 hours. Lastly, we shall package the aluminum foil when it has cooled. In order to prevent damage to the aluminum foil, we employ a hanging packing technique. Then, to prevent the aluminum foil from being lost during transit, we will utilize hardwood boxes without fumigation on the exterior layer.

Customers often require a roll diameter of 500–550mm, however HTMM's food-grade 7mic and 1235 alloy aluminum foil can offer a maximum roll diameter of 600–650mm. Customers often require a roll diameter of 500–550 mm, however our big rolls of 7mic and 1235 alloy aluminum foil may deliver a maximum roll diameter of 600–650 mm. Each huge roll of aluminum foil may weigh between 480 and 580 kilograms. We can manufacture our huge rolls of 8011 aluminum foil to meet the demands of our customers. Customers may tailor the huge rolls of 1235 alloy items they want by just giving us the size.

Excellent 1235 aluminum foil has several uses, particularly in electrical components, flexible packaging, medicines, and insulating materials. Manufacturers across a range of sectors choose it for its high purity, superior barrier qualities, and adaptability. Demand for 1235 aluminum foil is predicted to increase as businesses continue to place a higher priority on efficiency and sustainability, hence enhancing its standing as a crucial part of contemporary production and packaging solutions.