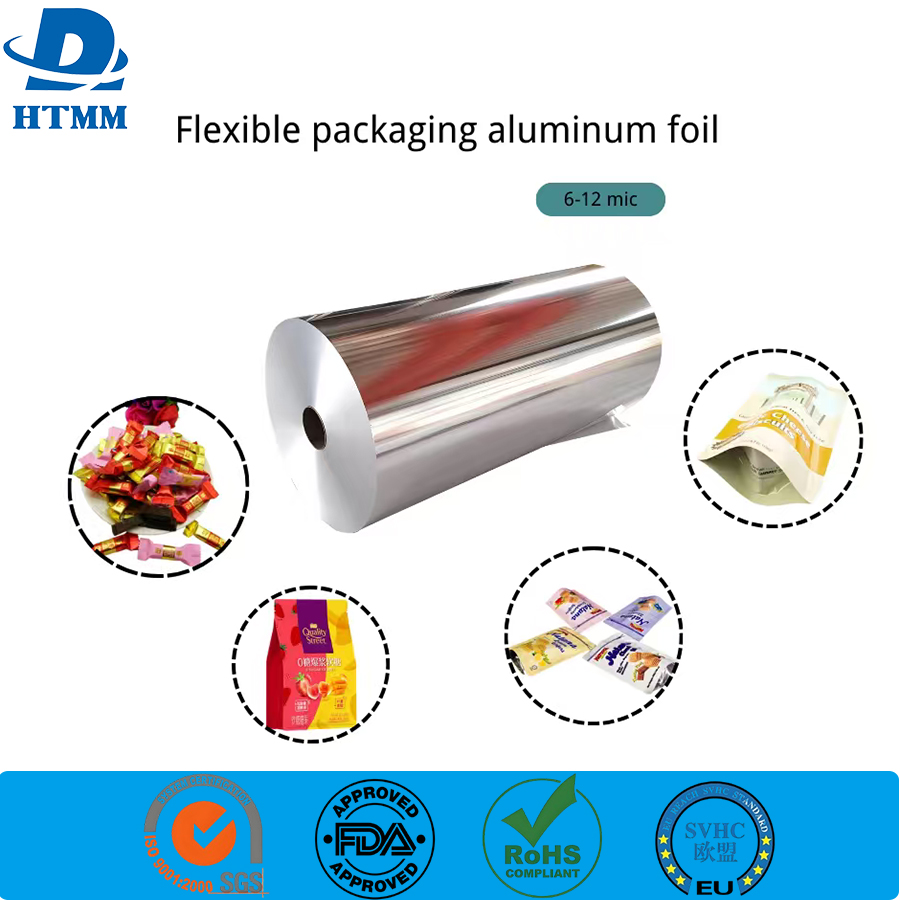

8079 aluminum foil is basically 8079 grade aluminum foil that has been annealed, making it softer and easier to shape than rigid aluminum foil. Aluminum foil rolls are its only big rolls, convenient to use in large quantities for factories or homes, thus saving a lot of trouble. Let’s start with the food industry, its main battleground. We see it in the small packages of candy and tea, and in the soft packaging of milk and juice. why? Because it’s non-toxic, it doesn’t have a weird taste, and it can prevent moisture, seal air, block sunlight, and lock in aromas, allowing food to last longer and maintain its flavor. They are also commonly used in takeout containers and inside linings of airline food boxes, ensuring cleanliness and hygiene while providing some degree of insulation. If homemade aluminum foil rolls are made, they are a kitchen wonder. Wrapping ingredients for grilling skewers or baking cakes prevents them from sticking to baking pans, reduces nutrient loss, and eliminates the need for greasy cleaning of pots and cakes. Whether you are a housewife or a restaurant chef, you cannot live without it.

8079 aluminum foil is basically 8079 grade aluminum foil that has been annealed, making it softer and easier to shape than rigid aluminum foil. Aluminum foil rolls are its only big rolls, convenient to use in large quantities for factories or homes, thus saving a lot of trouble. Let’s start with the food industry, its main battleground. We see it in the small packages of candy and tea, and in the soft packaging of milk and juice. why? Because it’s non-toxic, it doesn’t have a weird taste, and it can prevent moisture, seal air, block sunlight, and lock in aromas, allowing food to last longer and maintain its flavor. They are also commonly used in takeout containers and inside linings of airline food boxes, ensuring cleanliness and hygiene while providing some degree of insulation. If homemade aluminum foil rolls are made, they are a kitchen wonder. Wrapping ingredients for grilling skewers or baking cakes prevents them from sticking to baking pans, reduces nutrient loss, and eliminates the need for greasy cleaning of pots and cakes. Whether you are a housewife or a restaurant chef, you cannot live without it.Looking at drug packaging, this is where 8079O aluminum foil really shines. Many of the capsules and tablets we take are packaged in blister packs, and the aluminum foil that seals the caps is almost always made from them. Its excellent sealing effect keeps out air and moisture, thus maintaining the efficacy of the drug without easily losing its effectiveness. Moreover, it is stronger than ordinary aluminum foil, less likely to break during machine stamping and packaging. It is preferred by high-quality drugs with strict packaging requirements. Large purchases of aluminum foil rolls by pharmaceutical companies can be supplied directly to automated production lines, allowing the drug to be packaged quickly with exceptional efficiency. The new energy sector is also now visible. The outer protective shell of lithium battery pouches is made from it; It’s soft, corrosion-resistant, and makes the battery lighter, perfectly meeting the lighter weight requirements of new power vehicles. It’s also used in high-quality packaging for cable insulation, lightweight insulation layers in buildings and ships, and even cosmetics—it can be found in everything from our everyday food and beverages to industrial manufacturing.

| Description | Aluminum Coils 8079 HO For Flexible Packaging |

| Material | aluminium Coil |

| Shape | aluminum foil jumbo roll |

| Alloy | 1235 8079 |

| Length | Jumbo roll |

| Usage | food, flexible packaging, cigarette pack, etc |

| Core ID | 76mm 152mm |

| Thickness | 0.006-0.03mm |

| Width | 200mm-1600mm |

| Package | Wooden case |

| delivery time | 30days-35days |

| payment | T/T,L/C |

| quality tolerance | >99.5% |

| cerfificate | ISO9001:2000, FDA, EU ROHS, SVHC |

| manufacturer | Henan tendeli metallurgical materials Co., Ltd |

The first step is to extract the aluminum from the ore. First, bauxite with high aluminum content and low impurities must be mined. Once it is taken to the smelter, the "Beyer process" is used for purification—simply put, the ore is soaked in alkaline water, which precipitates as aluminum hydroxide. This is followed by repeated filtration and washing, and then firing at high temperatures to obtain alumina powder of greater than 99% purity. This powder is then placed in an electrolytic cell, electrified and mixed with the flux. The aluminum ions in alumina turn into liquid metallic aluminum, essentially extracting the aluminum "fertilizer" from the rock. The second step is to billet the aluminum alloy. 8079 Aluminum foil is not pure aluminum; Small amounts of iron and silicon are added to the molten aluminum to make the foil stronger and easier to shape. These materials are stirred evenly in a large furnace to create an 8079 aluminum alloy liquid, which is then poured into thick aluminum billets. To ensure a high-quality aluminum billet, surface impurities and minor defects must be removed, followed by heat and heat treatment to create a more uniform internal structure, in preparation for subsequent thinning. The third step is thinning and annealing, which directly determines the thinness and usability of the aluminum foil. First, the aluminum billet is placed in a roughing mill and rolled several times to transform it from a millimeter thickness to a strip just a few millimeters thick. Then, it enters a finishing mill, precisely pressing it to a very thin state of 0.01-0.02 mm, thinner than a sheet of paper. Once rolled, however, the aluminum foil becomes hard and brittle, requiring a period of high heating and heat treatment—annealing—to return it to a soft, oxidized state that allows it to be easily bent and shaped. This entire rolling process is repeated dozens of times, and the pressure and speed of the machine must be precisely controlled; Otherwise, small holes and wrinkles will appear in the aluminum foil, making the roll unusable. The last step is slitting and winding. The rolled 8079 O aluminum foil is cut into strips according to the width required by the customer, and then rolled by machine into neat aluminum foil rolls. Make sure that the foil does not deflect or wrinkle during the rolling process, and that the weight and size of the roll meets the requirements. Finally, before the aluminum foil roll is deemed fit and can be shipped out, it is checked again to ensure there are no small holes or dirt.

Packaging is especially important for aluminum foil for rolls. Bad packaging can easily cause damage during transportation and storage. Different sizes of aluminum foil require different packaging methods, especially for rolls, where both safety and transport efficiency must be considered. First, let’s discuss smaller sized aluminum foil products, such as household aluminum foil and small packets of pharmaceutical aluminum foil. Typically packaged in three layers: a plastic bag, a colored box and a cardboard box. The inner layer is tightly sealed with a polyethylene plastic bag to prevent moisture and oxidation. Product information and usage instructions are printed on the colored box in the middle, making it easy for supermarkets and consumers to understand. The outermost corrugated cardboard box is pressure resistant and shockproof; Typically, 25 rolls are packed into a large cardboard box, then placed on a pallet for easy stacking in supermarkets and pharmacies. Now let’s look at the large industrial aluminum foil rolls. Packaging must be designed for long-distance transport and large-scale storage. A common combination is plastic film, moisture resistant paper, and wooden pallets/boxes. First, wrap a layer of plastic film around the surface of the aluminum foil roll for moisture protection and sealing; then wrap in a layer of moisture-proof paper to further seal moisture; Finally, choose the outer packaging according to the transport method. Use a pallet for domestic shipping, wrap it in film to protect it, and keep the aluminum foil roll from rolling around; If it is for export, it must be used in smoked wooden boxes to comply with international shipping regulations for insect and mosquito prevention. The outer packaging must also clearly indicate the manufacturer’s name, aluminum foil model, size, batch number, etc. Some may even print exclusive logos to suit the customer’s needs.