8011 Aluminum Foil Roll Properties and Advantage

High-grade aluminum alloys, particularly 8011 alloy, which is renowned for its exceptional qualities, are used to make 8011 aluminum foil rolls. Excellent strength, resistance to corrosion, and thermal conductivity characterize this alloy. As part of the 8xxx series, 8011 is renowned for having outstanding corrosion resistance and a high tensile strength. The tensile strength of the aluminum alloy 8011 is higher than that of other alloys. Because of this, 8011 is a better choice for applications that call for higher strength and resistance to deformation. Thus, 8011 alloy is a perfect option for packaging applications. The jumbo roll packaging type is adaptable and may be used for a variety of packaging applications across several sectors.

Generally speaking, flexible packaging and kitchen foil are two applications for 8011 alloy. Although 8011 aluminum foil rolls are utilized for various uses, their thickness differs from other types of aluminum foil in the industrial sector.

Because of its special qualities that improve product presentation and preservation, aluminum foil is the preferred material for packaging. There are several benefits to packing with aluminum foil, such as:

Protection against light, oxygen, moisture, and pollutants: Aluminum foil creates a barrier that protects the integrity and freshness of items that are packaged.

Thermal conductivity: Aluminum foil works well for cooking and heat sealing because it allows heat to be transferred more easily.

Aluminum foil is sturdy, resilient, lightweight, and doesn't add extra weight to packaging while maintaining its durability.

Recyclability: Since aluminum foil is entirely recyclable, it encourages the use of ecologically beneficial and sustainable packaging materials.

About HTMM Aluminum Foil Factory

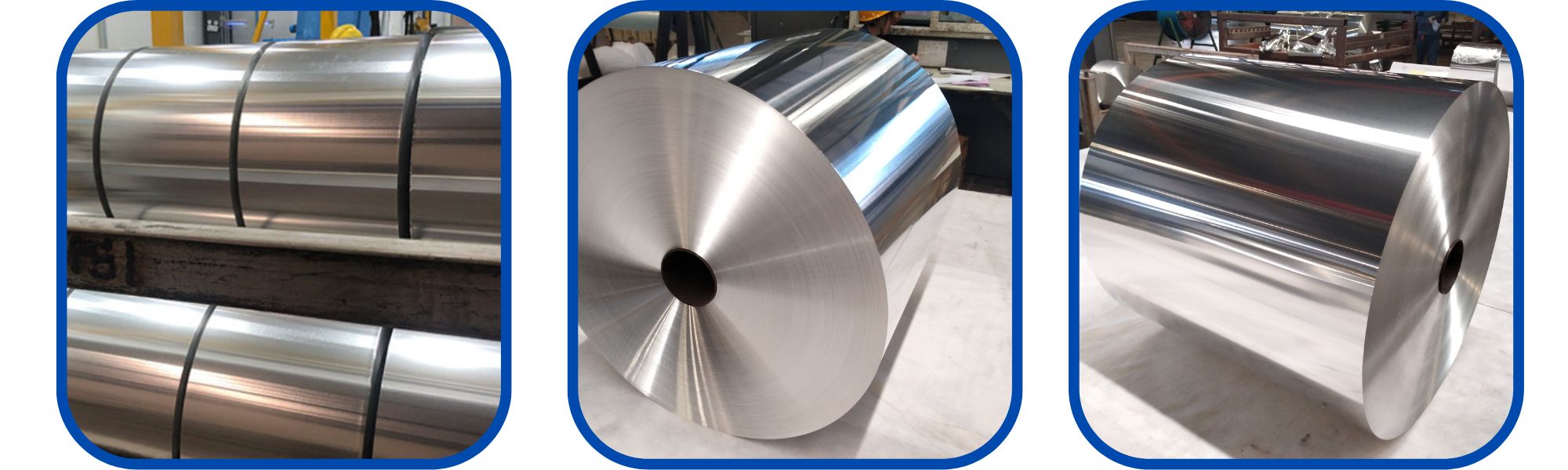

Since our establishment in 2009, more than 80 million tons of aluminum have been produced annually at HTMM Aluminum. To guarantee the dependability of the quality of our products, we fully abide by international quality standards like ISO 9001. Aluminum ingot processing, rolling, chilling, annealing, cooling, and other procedures are all part of our factory's manufacturing process. Our rolling machine uses an ABB plate control system and a HONEYWELL thickness control system throughout the rolling process to guarantee that clients receive big rolls of 8011 aluminum foil in a variety of thicknesses. Our best-selling items are 8011 composite foil and 8011 big rolls of home foil.

Customers often want a roll diameter of 450–500mm, however our premium 8011 home aluminum foil can deliver a minimum roll diameter of 350–360mm. We can make our huge rolls of 8011 aluminum foil to the specifications provided by the customer. All we need from customers is the size to customize the huge rolls of 8011 household foil items that they need. Typically, we supply our 8011 big aluminum foil rolls to manufacturers that rewind, make, and market tiny rolls. Once international clients buy our aluminum foil, they can break it into small rolls using a rewinder in their own plants before selling it to our final customers.

Of course, we can also give you a few little rolls of foil for your home. Our plant has also expanded into the production of tiny rolls in order to satisfy the demands of various customers. Since we are a producer of big roll 8011 aluminum foil, we can ensure our quality since we supply all the raw materials needed to produce tiny rolls from our own facility. In contrast to other producers of tiny rolls of aluminum foil, we ensure that every roll has an adequate number of meters and aluminum net weight. We can also tailor small rolls of household aluminum foil to clients' specifications regarding the number of meters per roll, the appearance of the box, and other factors.

Typically, makers of flexible packaging, aluminum foil packaging, etc. are the buyers of our 8011 composite foil. The sustainability and aesthetics of packaging materials are important factors in the packaging industry. Wooden packaging with 8011 aluminum foil rolls are the ideal combination of style and eco-friendliness. By using renewable resources, wood packaging not only improves packaging's aesthetic appeal but also raises awareness of environmental issues.

Wood packaging and 8011 aluminum foil rolls come together to produce a superior packaging option that is unique in the marketplace. Thinner aluminum foil, ranging in thickness from 6.35 to 6.5 microns, is used by several producers worldwide to create aseptic liquid packaging. It is coupled with wood components and used to liquid packaging. The smooth aluminum foil coating contrasts with the organic texture and earthy tones of wood, resulting in a visually pleasing but utilitarian combination.

There are several applications and packaging possibilities for 8011 aluminum foil rolls with wood packaging

Food packaging: To ensure the safety and freshness of perishable items, a combination of wood packaging with 8011 aluminum foil rolls is perfect.

Pharmaceutical packaging: Because pharmaceutical packaging is so concerned with maintaining the integrity of the product, aluminum foil is the material of choice due to its superior barrier qualities.

Cosmetic packaging: Aluminum foil keeps outside elements from harming cosmetics, while wood packaging gives cosmetic packaging a hint of elegance.

Industrial packaging: 8011 aluminum foil rolls are strong and adaptable, making them ideal for industrial packaging of electrical and mechanical components, among other items.

Overall, in the packaging sector, 8011 Aluminum Foil Roll and Wood Packaging is the ideal fusion of sustainability, quality, and aesthetics. Utilizing the distinct qualities of aluminum foil and the inherent allure of wood packaging, companies may improve their packaging options to satisfy contemporary consumers. This premium packaging solution redefines the art of packaging, allowing you to embrace innovation and sustainability.

With over ten years of trade experience, professional services, and a strong understanding of aluminum manufacturing, HTMM has established itself as a leading manufacturer of aluminum foil and has gained a positive reputation in the market. Our objective is to become your trustworthy partner for all of your needs related to purchasing aluminum foil!