8079 Aluminum foil sounds like an industrial code formula, but in fact it's been quietly sneaking into your everyday life for a long time - especially the pack of cigarettes in your hand. This type of aluminum foil is not ordinary "tin foil," but a "high-end" metal film composed of more than 99% pure aluminum and less than 1% iron and silicon.

8079 Aluminum foil sounds like an industrial code formula, but in fact it's been quietly sneaking into your everyday life for a long time - especially the pack of cigarettes in your hand. This type of aluminum foil is not ordinary "tin foil," but a "high-end" metal film composed of more than 99% pure aluminum and less than 1% iron and silicon.Ordinary aluminum foil (such as kitchen foil) will break when torn and tear after a few folds, but 8079 aluminum foil can withstand the "abuse" of high-speed packaging machines - it is stretched, folded, and cut on assembly lines of 600 packs per minute, and remains intact. All of this is due to the 1% iron and silicon, which supports the "rebar"-like aluminum foil skeleton, making it 30% stronger than plain aluminum foil.

Even more amazing is its thickness - 0.006~0.007 mm Aluminum Foil For Cigarette Packing, which is about a tenth of a hair. It's so light and can be moisture-proof, light-proof and odor-proof, depending on the natural "sealing superpower" of aluminum. Normal plastic film doesn't block water vapor and oxygen at all, but 8079 Aluminum Foil For Cigarette Packing is like a layer of "metal armor" for cigarettes, keeping the tobacco as fresh as ever.

Cigarettes are most afraid of three things: moisture, odor transfer, and light.

• Moisture: Tobacco absorbing water vapor will degrade the flavor at best, and at worst it can become moldy and carcinogenic. 8079 Aluminum foil has nearly zero water vapor permeability, which is more reliable than safe.

• Flavor transfer: The spices and nicotine in tobacco are very volatile, and normal products don’t quite hold it. But the Aluminum Foil For Cigarette Packing can lock in the flavor firmly, and it won't turn into a "zombie cigarette" even after a year and a half.

• Light: Ultraviolet rays will accelerate tobacco degradation, and aluminum foil is highly reflective, the equivalent of putting "sunglasses" on a cigarette

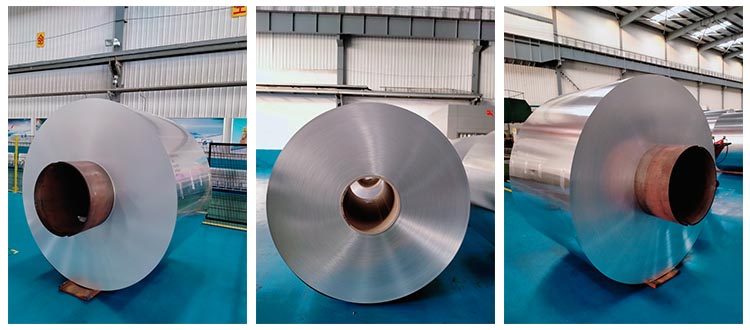

Don't underestimate its thinness. The difficulty of producing 8079 aluminum foil is comparable to that of making chips. The whole process has to go through three "tortures": hot rolling → cold rolling → annealing:

♦ Hot rolling: The aluminum ingot is heated to 500℃ and pressed into a 3mm thick strip. This step determines the toughness of the aluminum foil.

♦ Cold rolling: Repeated rolling at room temperature until the thickness is less than 0.01mm, which is 10 times thinner than A4 paper.

♦ Annealing: Use high temperature to perform "SPA" treatment on the aluminum foil to eliminate internal stress and make it soft and tough.

The most critical indicator is the "number of pinholes"-the number of micropores on the aluminum foil per square meter cannot exceed 20. If there are too many pinholes, the moisture-proof performance will collapse directly, which is equivalent to opening a "back door" for water vapor.

Aluminum Foil For Cigarette Packing is a "top trend" in the cigarette industry, but its efficiency tree is so much more than that:

Medical packaging: Aluminum foil must be used in the blister packaging of tablets and capsules, as it can separate 100% oxygen and bacteria, which is much more reliable than plastic. During epidemics, some manufacturers also used it as a sealing layer for vaccine bottles.

Food storage: 8079 6 micron aluminum foil is also used in high-end snacks (such as chocolate and nuts). Its preservation effect is better than plastic bags, allowing food to double its shelf life.

Industrial products: electrode coatings of lithium batteries, insulation layers of buildings, and even spacecraft insulation films can see their shadows.

Even more paradoxically, it’s actually more environmentally friendly than paper! 6 micron aluminum foil can be infinitely recycled, and 1 ton of waste aluminum foil can be used to regenerate 0.9 tons of new products, and the energy consumption is only 5% of mining and smelting aluminium. The so-called "environmentally friendly paper packaging" can only be incinerated at the end because it is coated with a plastic film.

aluminum foil 8079 alloy is like the "air" of the industrial world - no one cares about it, but without it the entire modern packaging system would collapse. The next time you open a box of cigarettes, you might as well look at the silver film against the light. It is a molecular miracle of human physics.

The speed of a modern cigarette factory production line is ridiculously fast - 600-800 packs of cigarettes per minute, which is more than 10 packs per second. Under such high-speed operation, ordinary materials are prone either to breaking off, or to contaminating the tobacco by abrasion, resulting in metallic debris. But the strength and flexibility of aluminum foil 8079 alloy is stuck in just the perfect balance point:

The tensile strength is 120-150MPa (equivalent to car seatbelt material), and it doesn’t break even when pulled at high speeds;

The surface roughness is ≤0.2 microns (smoother than a mirror), and it does not scratch the roller of the packaging machine.

A certain China Tobacco Group has done comparative tests: when using 8011 aluminum foil, the machine has to be stopped twice every 8 hours to clear debris, and each time it loses 15 minutes; After switching to 8079 aluminum foil it can run continuously for 24 hours without any failures. In total, a production line can earn an additional 3.7 million yuan per year! Not to mention the maintenance costs and scrap rates saved.

There are always people who want to replace 8079 aluminum foil with cheaper aluminized film, but the reality is very bleak - aluminized film cannot survive in the cigarette packaging industry!

The principle of aluminized film is to spray a thin layer of aluminum on top of the plastic film. It looks like aluminum foil, but performs much worse:

Collapse in moisture resistance: The water vapor permeability of the aluminized film is 50 times that of 8079 aluminum foil, and the tobacco will be damp after three months;

Creases will crack: When the packaging machine is folded, aluminum molecules in the aluminized layer will fall off, resulting in "light-transmitting cracks" (called the "pinhole effect" in the industry);

High temperatures reveal the true form: when cigarettes are transported through the equator, the high temperatures will cause the plastic base film to deform and the aluminum layer to peel off directly.