From crunchy snack bags to coffee packaging to preserve flavor, foam masks to protect chemicals to tetra pak to extend milk shelf life, on the colourful supermarket shelves, materials with excellent protection and flexible processing With this "invisible" method, aluminum foil for flexible packaging deeply shapes the modern consumer life and industry. In particular, under the blessing of high efficiency composite processing technology represented by "three layers of common pressure control wire", the aluminum foil base material has changed from a simple blocking material to a core carrier of multi-functional, high-performance packaging solutions, driving the transformation and upgrading of the packaging industry.

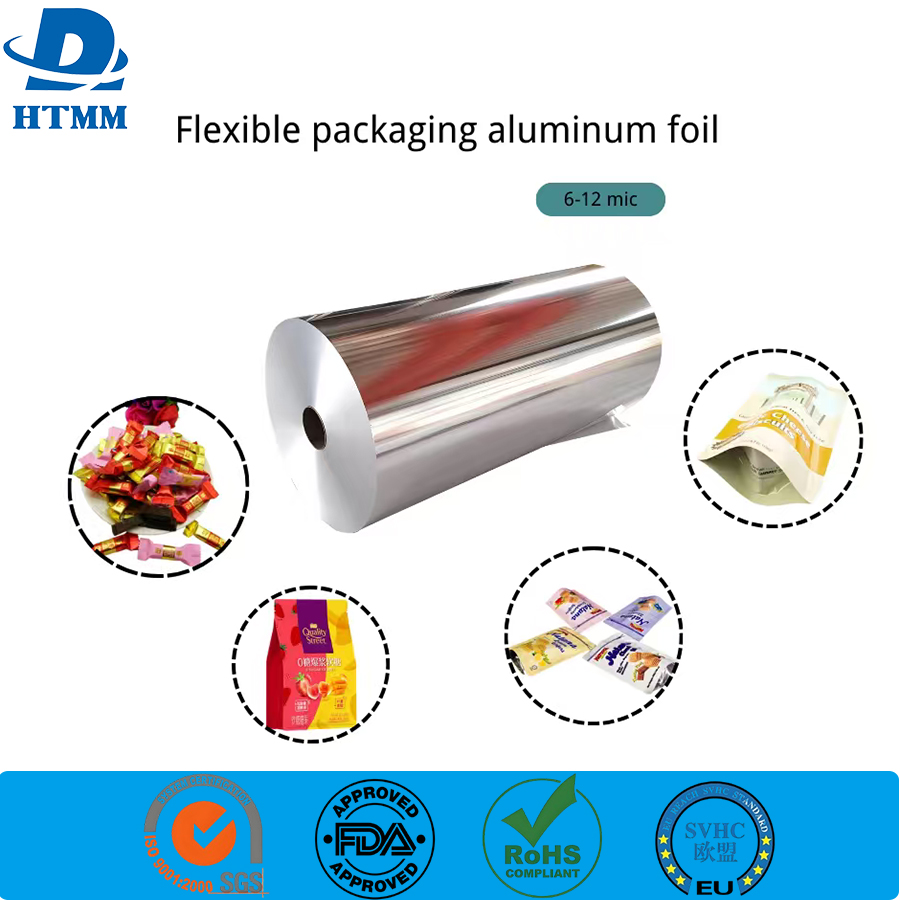

From crunchy snack bags to coffee packaging to preserve flavor, foam masks to protect chemicals to tetra pak to extend milk shelf life, on the colourful supermarket shelves, materials with excellent protection and flexible processing With this "invisible" method, aluminum foil for flexible packaging deeply shapes the modern consumer life and industry. In particular, under the blessing of high efficiency composite processing technology represented by "three layers of common pressure control wire", the aluminum foil base material has changed from a simple blocking material to a core carrier of multi-functional, high-performance packaging solutions, driving the transformation and upgrading of the packaging industry.Aluminum foils occupy their place as key materials for flexible packaging because of their irreplaceable properties. First, it has almost perfect blocking performance. Aluminum foil has excellent shielding effect against light rays (especially ultraviolet rays), oxygen, water vapor and various odors, can effectively prevent the content from receiving light oxidation, absorption degeneration or flavor loss, food, medicine, precision electronic components and other storage Provides "armor" like protection for environmentally demanding products. Then, with good thermal conductivity and heat resistance, it can adapt to the high temperature sterilization (e.g. bsteed packaging) process, can also meet the cold chain storage demand. In addition, because aluminum foil is soft, it is easy to combine with plastic film and other materials. Because it is excellent in plasticity and decoration, it can achieve beautiful printing effect and complex modeling design, which can improve the value of goods. Due to these properties, the thickness usually ranges from 6 to 7 micrometers to tens of micrometers, making it the "soul" material essential for high-end flexible packaging.

| Alloy/temper: | 8011 / 1235 O |

| Thickness: | 6 Micron (0.006mm)-10 Micron (10 micron) |

| Width: | 200mm-1850mm |

| Materials: | Aluminium foil Raw Materials |

| Length: | Aluminium foil jumbo roll |

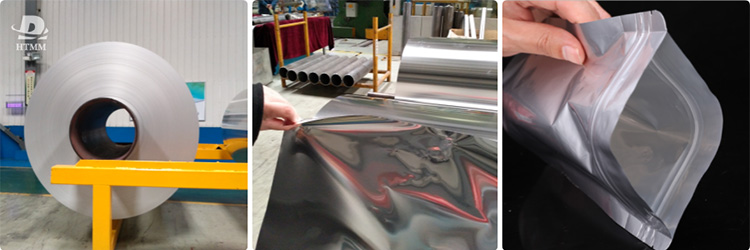

However, there are limitations to single aluminum foil, such as being prone to wrinkles and not being able to form pinholes or heat seals. For this reason, modern flexible packaging often adopts a complex structure, and the "three layers press" technology is the advanced technology model of this complex structure. Three-layer co-extrusion is the process of extrusion through a pre-sawmill containing three different performance polymer resins (e.g., polyethylene PE, polypropylene PP, nylon PA, ethylene vinyl alcohol copolymer EVOH, etc.) or aluminum foil through multiple channels. It is the processing method of forming multi-layer composite film or sheet with a mold head in a molten state. When aluminum foil is integrated into the system as an intermediate or functional layer, it becomes a typical sandwich structure.

This triple press structure, centered on aluminum foil, usually achieves functional optimization.

Outer layer (support/protection layer): always using materials such as polyester (PET), nylon (PA) or bi-directional stretch polypropylene (BOPP) to provide excellent mechanical strength, wear resistance, printing adaptability and optical performance The first line of defense and the image character of the package.

Intermediate layer (core blocking layer): a bonding layer of aluminum foil or aluminum foil with a high block polymer such as EVOH. This layer is the "heart" of the packaging function and is responsible for the ultimate blocking of gas, water vapor and light and ensuring the shelf life of the contents.

Inner layer (thermosealed layer): typically polyethylene (PE), flow-extended polypropylene (CPP) or its modified material is used. This layer should directly guarantee good thermal sealing performance, anti-contamination sealing capacity, chemical inactivation (food safety) and constant puncture resistance, sealing reliability of the package.

By applying the raw materials of aluminum foil to the press line in three layers, it is a precise fusion of material science and processing technology. The production line is usually: release winding and pretreatment unit (aluminum foil surface cleaning, corona treatment to strengthen adhesion), multi-layer co-pressure head (accurate control of melt flow rate and thickness distribution of each layer), complex cooling unit (thermal pressure or adhesion of each layer) It also includes post-processing units (e.g. line application, hardening, winding, etc.). The advantages of this process are obvious: integrated and efficient production, reducing the traditional complex process, improving efficiency and reducing energy consumption. The structure is more dense, the layer is fused together, the peeling strength is higher, the blocking performance is more stable and reliable; With high flexibility and the ability to adjust the material and ratio of each layer, we can "customize" and develop specialized materials to meet the needs of each product (braised, refrigerated, airpack, etc.).

Looking forward to the future, with the wave of sustainable development and the upgrade of consumption, the three-layer flexible packaging based on aluminum foil will evolve in two directions. First, high performance and weight reduction: thinner aluminum foil (6 microns without loss of performance) By developing high-performance resins, we have achieved material reduction and carbon footprint reduction while maintaining and improving packaging functionality. The aluminum foil itself can be recycled indefinitely, but the composite structure with plastic presents a challenge for recycling. In the future, it is important to develop single-material structures (for example, all polyolefin is used, but by process it has a barrier property similar to that of aluminum foil) and composite structures that are easy to separate and recover. At the same time, it actively explores green processes such as water-based adhesive and solvent-free composite, and complements the three layers of technology to promote the green transformation of the industry together.

Overall, flexible packaging aluminum foil material, such as 1235/8079, combined with advanced three-layer production line, is not only an important pillar of the current high-end packaging market, but also an innovative packaging solution for the future. It is the key cornerstone. It deeply embodies the wisdom of modern industry to achieve product protection, efficiency improvement and resource conservation through material innovation and process upgrading. With the continuous breakthrough of technology, this "golden partner" must play a more important role in safeguarding product safety, improving quality of life, and fulfilling environmental responsibility.