What Is a Good Flexibility for jumbo roll aluminium?

Aluminum foil 8011 is known for being a flexible material, but some grades of foil are significantly more pliable and conformable than others. Foil flexibility depends on factors like thickness, aluminum alloy, and the manufacturing process used. Understanding the different factors that influence foil flexibility can help you select the right grade for your application.

The Basics of Foil Flexibility

Thinner aluminum foil 8011 is inherently more flexible due simply to its reduced thickness. As little as 0.0001 to 0.0002 inch differences in foil thickness can significantly change flexibility, so gauges below 0.001 inch tend to be the most conformable. However, thinner foils also provide less strength and do not reliably maintain their shape when deformed.

Foil flexibility also depends on the aluminum alloy used, with pure aluminum foils bending more easily but also tearing more readily. Aluminum alloys containing small amounts of other metals like magnesium and silicon are stronger but slightly less flexible for a given thickness compared to pure 8079 aluminium foil.

The manufacturing process also influences flexibility, as annealed foils soften the metal making them more formable but less resistant to tearing. In contrast,8079 aluminium foil that are hard drawn or underwent cold rolling are somewhat less flexible but provide greater tensile strength.

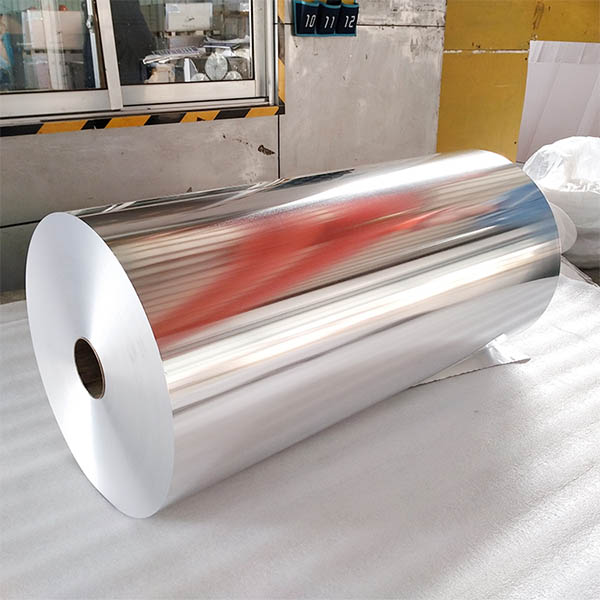

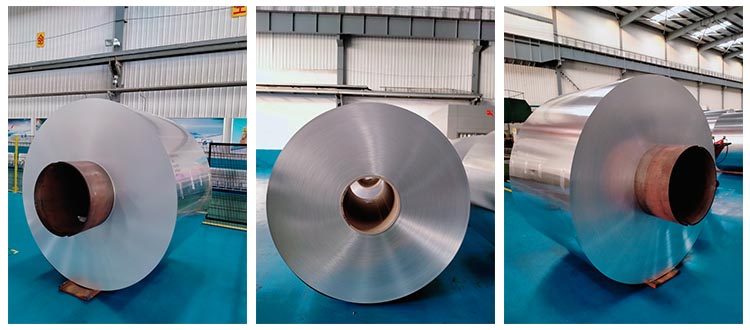

| Alloy/temper | 1235 8011 8079 3003 8006 / O H18 H22 H24 |

| Thickness | 0.0045mm-0.2mm |

| Width: | 50mm-1550mm |

| I.,D | 76mm 152mm |

| O.,D | 330mm-550mm |

| Usage | insulation,flexible packaging,lamination,cable,household use,food container |

Selecting Foil for Different Flexibility Needs

To select the right grade of foil based on flexibility requirements:

• For extremely conformable foil: Choose gauges under 0.001 inch thick, preferably annealed or softened foil made with pure aluminum rather than an alloy. These ultra-flexible foils conform well to complex shapes but offer lower tensile strength.

• For good all-around flexibility and conformability: Select 0.001 to 0.003 inch foil, ideally pure aluminum that is annealed or soft tempered. These thicker gauges provide some strength while still conforming well to contours.

• For moderate flexibility with good strength: Opt for 0.002 to 0.004 inch alloy foils that undergo a full hard draw or cold rolling process. They balance flexibility with notable tensile strength.

• For somewhat rigid roll jumbo aluminium able to maintain its shape: Choose 0.004 to 0.006+ inch hard drawn alloy foils. These thicker gauges conform somewhat during shaping but largely retain their molded or formed condition.

In applications where extremely conformable yet strong foil is important, manufacturers offer options like stretch leveled foil or factory shaping processes to enhance flexibility at a cost premium. Machine direction grain orientation can also impact how uniformly foil bends in various directions.

Combining Factors for Desired Flexibility

For the best combination of flexibility and performance, consider how multiple factors work together:

• Thinner gauge + pure aluminum composition + annealed temper = Extreme conformability and flexibility but lowest strength.

• Thinner gauge + pure aluminum composition + hard drawn temper = Very flexible foil with some increase in tensile strength.

• Medium gauge + alloy composition + hard drawn or temper = Good overall flexibility with notable tensile strength. Balanced properties.

• Thicker gauge + alloy composition + hard drawn or cold rolled temper = Somewhat rigid foil that largely maintains molded shapes but with high tensile strength.

So for the ideal flexibility in your aluminium foil paper roll application, evaluate gauge or thickness, aluminum composition, manufacturing process and temper or temper designation together to find the grade that delivers the right balance of conformability and the strength required. If in doubt, consider testing multiple foil options to determine which gauge and specification most closely matches your flexibility and performance needs.

In summary, aluminium foil paper roll flexibility depends most significantly on foil thickness, with thinner gauges offering the greatest conformability. However, the right combination of aluminum alloy, manufacturing process and temper can significantly adjust foil flexibility for a given thickness. By evaluating all related factors together, you can select the foil grade that provides the ideal combination of conformability, strength and other properties for your specific application.

Premium Aluminum Foil for Catering and Hospitality Services

When caterers and restaurants need rigid yet durable containers, appealingly wrapped food, and effective long-term storage for leftovers, premium aluminum foil becomes a crucial resource. High-end catering and hospitality businesses demand foil that meets exacting standards for quality, flexibility, resistance to wear and heat, and aesthetic appeal.

Advantages of Premium Foil for Catering

Premium aluminum foil offers several benefits for catering and hospitality businesses:

• Superior Flexibility - Premium foil tends to be made with pure aluminum and undergoes annealing and other treatments to become extremely conformable and form fitting. This allows the foil to shape perfectly around intricate dishes and containers.

• Resistance to Wear and Tear - The highest quality aluminum foil uses thicker gauges between 0.002 and 0.005 inches that withstand the rigorous demands of catering, from transport to high-volume buffet lines. The foil remains intact without tearing.

• Reflective Shine - Premium foil offers a bright, mirror-like shine that makes food visually appealing and matches the upscale image caterers aim to project. The unblemished surface also meets health department standards.

• Excellent Heat Resistance - Premium foil withstands temperatures up to 500 degrees Fahrenheit without melting, warping or emitting odors, safely containing hot foods during transport, reheating and serving.

• Reduces Waste - Since premium foil is durable and flexible, less material is needed. This minimizes waste during food prep and serving.

• Meets High Standards - Premium foil meets the most stringent regulations for food contact and purity, conforming to guidelines set by the FDA and NSF.

• Low-Cost Versatility - Despite a higher initial cost, premium foil's flexibility and durability allows it to be reused multiple times, keeping overall expenses down.

Characteristics of Premium Foil Grades

Premium grades of aluminum foil for catering exhibit several key characteristics:

• Thickness - Gauge between 0.002 and 0.005 inches to provide sufficient rigidity yet enough flexibility to form around dishes.

• Purity - Made with 99-100% pure aluminum for maximum flexibility without compromising heat resistance or purity.

• Temper - Annealed or soft tempered to enhance conformability and ease of shaping around containers.