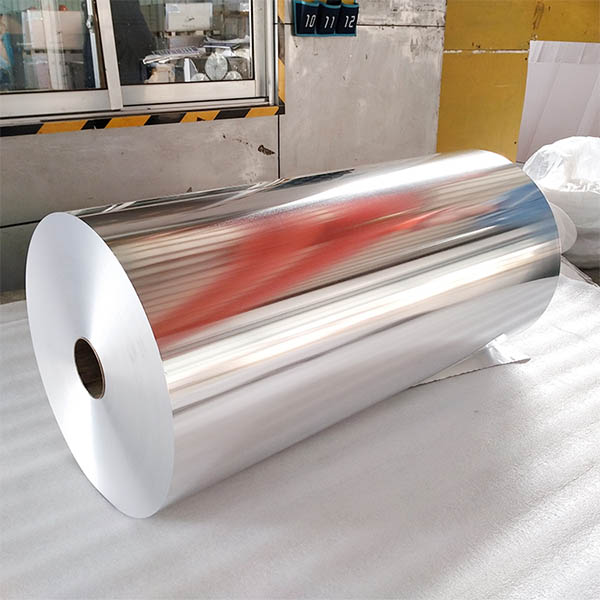

In the construction industry, 1235 aluminum foil is widely used in insulation. As a well-known brand in the aluminum processing industry, HTMM Aluminum foil products meet national standards and achieve customer satisfaction. Currently we can supply various high quality products for the food manufacturing industry. Based on quality assurance of appearance and appearance, we can prevent the appearance of black oil stains, bright lines, roller printing, small black silks, scratches, bumps and net shows.

Today, we own and operate a variety of businesses and invest in sustainable enterprises. HTMM provides unique knowledge and capabilities through its operations in a wide range of markets, including aluminium. HTMM is committed to leading the way to a more sustainable future, to create a more sustainable society by developing natural resources into products and solutions in innovative and efficient ways.

Wrap the material tightly around the food when used to chill or freeze it, it works well to reduce moisture transfer, odor emission and vapor transfer. When refrigerating foods, wrap foods in plastic wrap first and then wrap them tightly in foil. To trap oxygen and prevent frostbite in frozen foods. Line a plate with foil for easy cleanup if you catch drips from pies, fruit, meat and poultry.

| Alloy/temper | 1235/O |

| Thickness | 0.0045mm-0.05mm |

| Width: | 50mm-1550mm |

| I.,D | 76mm 152mm |

| O.,D | 330mm-550mm |

| Usage | insulation,flexible packaging,lamination,cable |

It can be quality assured to be shaded, not falling, dark, non-polluting and free. It is moisture resistant and used for decorative packaging of high quality cigarettes and confectionery. Plain Aluminum Foil Jumbo Roll 1235 Soft Temper is widely used, such as aviation food packaging, general meat packaging, cigarette packaging and so on.

flexible packaging and food contact applications. Woven, bubbled and laminated with EPE, XPE foam as an insulation material, can be used as pillows, wall wrap, to make umbrellas or ice packs; Used as a first aid blanket, it can retain a percentage of 80% of the body’s radiant heat. Make electrostatic protective bags for electronic products.

1235 Aluminum foil is a versatile material that finds numerous applications in various industries. It has become a popular choice for many applications due to its exceptional properties and characteristics.

1235 One of the primary uses of aluminum foil is in the packaging industry. Its excellent barrier properties make it an ideal choice for packaging food, beverages, pharmaceuticals, and other perishable products. The foil acts as a protective barrier, preventing the entry of moisture, oxygen, light and other contaminants that can compromise the quality and shelf life of the packaged product. Furthermore, the foil provides excellent thermal resistance, keeping the products fresh and unaffected by external temperature variations. It can be used for a range of packaging forms, including pouches, blister packs, and wraps, because to its adaptability and simplicity in shape and molding.

Due to its high thermal conductivity, it can effectively reflect radiant heat, which lowers energy use and raises the building's overall energy efficiency. Foil is frequently utilized on HVAC systems, roofs, and walls as radiation barriers in order to reduce heat transmission and maintain a comfortable indoor atmosphere. Additionally lightweight and easy to handle and install, they save building costs.

1235 Aluminum foil is useful in the electrical industry as well. It is the best material to use when producing capacitors, transformers, and other electrical components due to its outstanding electrical conductivity and resistance to corrosion. Electrical impulses are efficiently carried using foils as conductors while retaining stability and dependability. Due to its high level of purity, there are almost no impurities that could harm the electrical functionality of the components.

Additionally, the automotive sector uses 1235 aluminum foil for heat exchangers, radiators, and a number of engine parts. It is a great option for boosting the efficiency and performance of automotive systems because of its heat dissipation capabilities and lightweight design. To maintain the components' dependability and endurance in automotive applications, the foil's corrosion resistance is crucial.

In conclusion, aluminum foil 1235 is a flexible material with a variety of uses. It is a common option in the packaging, building, electrical, and automotive industries thanks to its barrier properties, thermal conductivity, electrical conductivity, and corrosion resistance. The use of 1235 aluminum foil is anticipated to grow into new and creative applications as technology develops, further proving its usefulness and adaptability in a variety of industries.

For a variety of reasons, 1235 aluminum foil is frequently used by businesses. First off, it is appropriate for industries needing a high level of cleanliness, such food packaging and pharmaceuticals, because to the pure, unadulterated products it ensures. The strong barrier properties of the foil effectively protect packed items from moisture, oxygen, light, and other outside elements, preserving their quality and extending their shelf life.

Second, 1235 aluminum foil is extremely flexible and can be easily bent, curved, and formed into a variety of shapes and formats. Due to its adaptability, it is the perfect material for packaging solutions because it can be made to fit a variety of product shapes and sizes as well as special packaging needs.

1235 The high heat conductivity of aluminum foil is another noteworthy benefit. It effectively reflects and dissipates heat, making it indispensable in thermal management applications like building insulation, heat exchangers, and automobile parts. It helps maintain a comfortable environment and saves energy by minimizing heat transfer while also improving efficiency.

Foils are also ideal for the electrical industry because to their corrosion resistance and electrical conductivity. It guarantees effective electrical signal transmission and lowers the chance of electrical interference or degradation. A reliable material for the production of capacitors, transformers, and other electrical devices, 1235 aluminum foil's resistance to corrosion ensures the durability and dependability of electrical components.

Additionally, the light weight of 1235 aluminum foil has several benefits, particularly in sectors like aerospace and automotive where weight reduction is crucial. This increases performance and sustainability while lowering overall vehicle weight and enhancing fuel efficiency.

In conclusion, selecting 1235 aluminum foil has a lot of benefits, such as high purity, remarkable barrier qualities, flexibility, thermal conductivity, electrical conductivity, corrosion resistance, and lightweight features. This material's qualities make it ideal for a variety of uses in the packaging, construction, electrical, automotive, and other industries. Aluminum foil made in the year 1235 is a popular option for people looking for effective, affordable, and ecological solutions because of its adaptability and dependability.