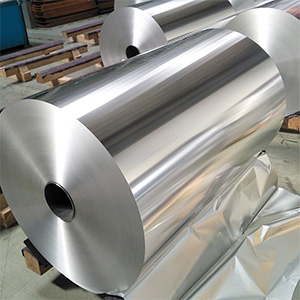

Customized production of 1235 food packaging aluminum foil

Aluminum foil packaging is based on 1235 aluminum foil, which is processed through subsequent compounding and printing processes. 1235 aluminum foil has good moisture resistance, is stable at high and low temperatures, and does not swell and deform at temperatures of -73 ~ 371 ° C. Thermal conductivity, thermal conductivity can reach 55%. Therefore, it can be used for high-temperature cooking or other heat treatment, as well as frozen packaging. The specific specifications of 1235 aluminum foil are as follows:

Typical alloy: 1235 aluminum foil

Material status: O

Thickness range: 0.006-0.007mm

Width range: 100-1600mm

Length range: C

Customer satisfaction is the greatest affirmation of the enterprise. In order to ensure the high quality of 1235 aluminum foil, HTMM introduces advanced foil rolling mills, strictly controls the raw materials, adopts reasonable processes, and inspects the layers during production. The cutting is not deformed and is praised by customers at home and abroad.

How much is the market price of 1235 aluminum foil for aluminum foil packaging per ton?

The price is a problem that customers are more concerned about. The direct influence factors of the price of 1235 aluminum foil are the price of raw materials and processing fees. The indirect influence factors include the strength of the manufacturer, the technical level, the sales model, and the geographical factors. specification.

1235 aluminum foil for packaging-each customer needs different specifications and dosages, and the manufacturers have different production difficulties, so the quotations are different. The specific price can be consulted online at any time. After understanding the specific needs, the customer service quickly arranges professional business one-to-one communication to provide the best product solutions and quotations.

As an aluminum foil manufacturer with decades of experience in producing various foils and alloys, we see significant growth in the market for ultra-thin and highly flexible packaging aluminum foils (such as the 7-micron thick alloy 1235). Due to its strength, barrier performance, recyclability, and ability to form various shapes at high speed on automated production lines, this ultra-thin grade has increasingly become the preferred material for many packaging applications.

In order to meet the growing demand, we have invested heavily in expanding the production capacity of 1235 Aluminum foil while improving manufacturing efficiency. This allows us to produce more 1235 alloy coils per hour to meet customer orders. Meeting the constantly growing demand has always been a continuous challenge, but continuous process optimization has led to the expansion of our production scale to meet the multifunctional applications driving aluminum foil consumption.

The Origin and Characteristics of 1235 Alloy

Alloy 1235 is a 1XXX series aluminum developed in the 1980s, specifically designed for foil applications. It contains a small amount of manganese, which can improve strength and corrosion resistance without affecting formability. Aluminum foil 1235 7 micron jumbo roll is good choose flexible packaging. At the 7 micron specification, the yield strength of alloy 81235 Alu foil allows it to tightly fit complex shapes or perform deep drawing, but it is still very flexible and easy to fold, making it suitable for packaging applications.

Its ultra-thin characteristics provide an effective gas and moisture barrier, while minimizing the use of materials. The high proportion of aluminum in this alloy also means that it can be fully recycled at the end of product life without affecting performance due to repeated recycling. These characteristics make 8079 alloy foil widely used in food and drug packaging, with barrier performance and sustainability being important factors for brand owners and consumers to consider.