This seems simple, but the actual process may not be easy. For example, when aluminum is pushed out, it will heat up. If the temperature is too high, it will stick to the roller, so the pressure of the roller must be carefully controlled.

When the thickness of the aluminum plate is 5 mm, it must be rolled again at the cold rolling stage. First, the sheet is rolled on a roll, and then sent to a cold rolling mill for final rolling. It is at this point that the bright and dark side of aluminum is created. Because aluminum is too thin now, the tension required to transport aluminum through cold rollers can easily break aluminum. Since the aluminum sheet has two surfaces, the aluminum surface in contact with the steel roller becomes smoother and more shiny, and the aluminum surface in contact with itself becomes matte.

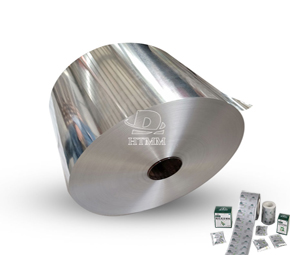

HTMM is a global supplier of aluminium foil, the products gauge range is from 0.006mm to 0.2mm, including pharmaceutical aluminum foil, household foil, container aluminum foil, cigarette aluminum foil, beer label aluminum foil, decoration aluminum foil, and the flexible packaging foil which can be applied in many aspects, such as the aseptic packing.