Part 1: What is 8011? The "golden formula" of domestic aluminum foil.

8011 is not just any number; It is an "identity card" of aluminum alloy. Just as gold has grades of 24K and 18K, aluminum has different formulas. The 8011 formula is an engineered "golden ratio" for home environments.

Its composition is simple: aluminum is the absolute main element, more than 98% of it; plus a little iron (about 0.5-0.8%) and a little silicon (about 0.4-0.8%). Don’t underestimate this addition:

Iron acts as a "skeleton," giving soft aluminum its elasticity and preventing it from cracking easily.

The silicone acts like a "lubricant," making the aluminum more manageable during processing, allowing it to be rolled out as thin as paper.

Part 2: Why 8011 specifically?

Because it strikes the perfect balance: soft enough (to wrap food tightly), strong enough (doesn’t puncture easily during use), and safe enough (meets food contact standards). From chocolate inner packaging to aluminum-plastic composite tablets, from airline meal boxes to your barbecue grill, 8011 is ubiquitous.

This process requires very high precision; The temperature, speed and pressure of the roller must be precisely controlled, otherwise the aluminum plate may break or become uneven in thickness.

| Alloy/temper: | 8011/O |

| Thickness: | 0.008mm-0.02mm 8 micron-20 micron |

| Width: | 280mm 290mm 300mm 450mm |

| I.,D: | 76mm 152mm |

Part 3: The Foil Rolling Miracle – The Magic of Thinness

When the thickness reaches about 0.5mm, the real magic begins. Since the thickness of the target is so thin (e.g., 0.01 mm), single layer rolling tends to break. Engineers invented "double-layer rolling": two layers of aluminum foil are stacked together, with lubricant in between, and passed together through a rolling mill. This produces two sheets at once while protecting the aluminum foil.

How do you measure the thickness of the thinnest aluminum foil? Factories use X-ray thickness gauges, which can monitor in real time with an accuracy of 0.0001 mm. This is 100 times more accurate than measuring hair with calipers.

Part 4: Annealing Rebirth – From "Tough Guy" to "Soft Girl".

After intense rolling, the aluminum foil becomes as hard and brittle as metallic card. This is where "annealing" comes into play: the aluminum foil roll is sent to a large annealing furnace and "sauna-ed" at about 300°C for several hours. During this process, the internal pressure of the aluminum foil is released, and it becomes soft again – this is the familiar, easy-rollable kitchen aluminum foil we know and love. Final step: slitting and packaging The huge "master rolls" (up to 2 meters wide and weighing several tonnes) are slitting in different widths: 30cm. Barbecue rolls, 20cm.

Part 5: Is it safe? Understanding the "health certificate" of aluminum foil Safety is paramount for products in direct contact with food. Valid 8011 domestic aluminum foil must contain this "passport":

Food Contact Material Test Report (Mandatory!) This is the "license" for aluminum foil to enter the kitchen. The test mainly focuses on two things:

Migration test: Simulate storage of acidic and oily foods, detecting whether leaching of aluminum ions exceeds standards.

The factory that produces 8011 aluminum foil is much more "intelligent" than you might imagine.

How advanced are the tools?

The key is rolling mills, especially foil rolling mills, where a unit can cost tens or even hundreds of thousands of yuan. Modern foil rolling mills are fully computer controlled, automatically adjusting pressure, speed and tension. Automated Guided Vehicles (AGVs) transport giant aluminum coils in workshops, while drones inspect from above—this is no longer a traditional factory, but an intelligent manufacturing model.

Where are the technological barriers?

Knowing the formula and process does not guarantee a good product. The real secret is:

How can the rolling oil be controlled to achieve a mirror-like surface on aluminum foil?

How do you set the temperature profile during annealing to achieve the perfect balance of softness and hardness?

How do you ensure smooth edges when ripping without cutting your hand?

These "skills" require years of accumulated expertise from the engineering team and are the factory's most valuable asset.

How strict is quality control?

Each batch of raw materials entering the factory must be examined using a spectrometer; On the production line, samples are taken every few minutes to check the thickness and the number of pinholes (not a single pinhole can be missed using the light transmission method); Finished products must be tested for tensile strength, elongation… Only products that meet all standards can leave the factory.

An excellent factory is not only a producer, but also a problem solver. For example, in response to user feedback that "aluminum foil sticks easily to food", they developed surface coating technology; And in response to environmental protection needs, they developed a single material structure that is easy to recycle.

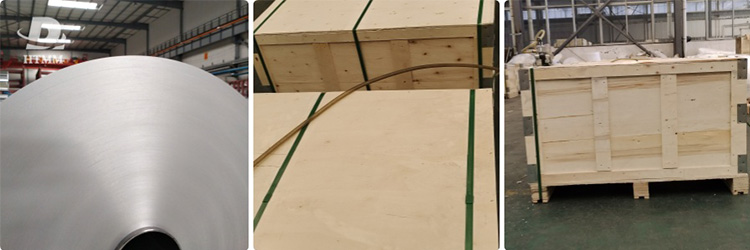

Aluminium Foil Raw Material Packing

The final rolls of aluminum foil are carefully packaged like precious treasures. Workers first wrap the gleaming aluminum rolls tightly with several layers of thick plastic film from start to finish, ensuring neutral humidity and dust protection. Then, the custom made sturdy wooden crates come in handy. The aluminum rolls are hoisted sequentially inside the crates, and the sides are firmly secured with wood strips and foam blocks to prevent movement during transport. Finally, the lid is discarded, and steel straps are attached, completing an "armour" marked with "handle with care" and moisture-proof labels. This packaging ensures that even after crossing the ocean, the aluminum rolls arrive in the hands of consumers as smooth and shiny as when they first came off the production line.