Food Grade Aluminum Foil Coil 8011

Aluminum foils is one of the most widely used materials in food preparation and storage. Its lightness, flexibility, heat conductivity and barrier properties make it exceptionally suitable for a variety of culinary tasks. Food grade aluminum roll 8011 represents the premium standard for food contact applications. Let's explore what distinguishes this variety and examine its key qualities and uses.

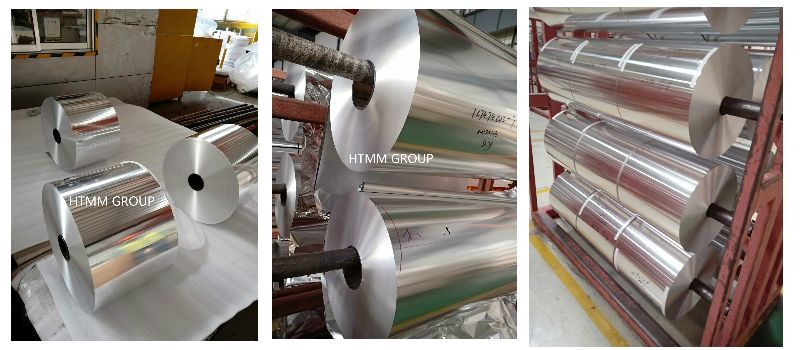

Food Grade Aluminum Foil Coil 8011 Specification

Food grade aluminum foil rolls conform to certain specifications that differentiate it from other varieties. Some important characteristics of an 8011 grade Aluminum roll include:

Thickness: Standard thickness is 0.0016-0.0021 inches (approximately 7-9 mils or 16-23 microns). This allows for sufficient strength and flexibility.

Alloy: Made from an 8011 alloy which is 93-98% pure aluminum with trace amounts of other elements like magnesium and manganese totaling under 7%.

Surface: Has a bright, shiny surface that provides a reflective barrier and non-stick properties ideal for food use.

Width: Available in rolls typically 12-16 inches wide to suit most domestic and commercial needs.

Length: Jumbo rolls can be 500-1000 feet long for convenient unrolled continuous sheets.

Packaging: Foil is wound tightly and sealed in protective wrapping to maintain freshness.

Certifications: Must carry appropriate FDA, EHS or equivalent food safety approvals for direct contact with edibles.

| Temper: | Soft Aluminum Foil |

| Use: | Kitchen Use |

| Treatment: | PLAIN , Net Aluminum Foil |

| Type: | Roll |

| Alloy: | Alloy 8011 Aluminum Foil |

| Thickness: | 0.008-0.04mm |

| Place of Origin: | China (Mainland) |

| Model Number: | 8011-O |

| Name: | Food packaging aluminium foil for household with high quality in china |

| Material: | Aluminum 8011 Alloy |

| Color: | Silvery |

| Width: | 200-1400 MM |

| ID: | 76mm/152mm |

| Application: | Food Wrapping |

| Certificate: | ISO9001,ISO14001,RHSAS18001,SGS |

| Packing: | Wooden Cases |

| Usage: | Ketchen Packing Storing Freezing |

| MOQ: | 3 Ton |

If you have any request Food Grade Aluminum Foil Rollls. please contact us.

Aluminum Foil Coil Composition and Benefits

The core element in an 8011 grade aluminum roll is its high purity aluminum content exceeding 93%. Aluminum is classified by the FDA as generally recognized as safe (GRAS) for food use.

Its malleability, light weight and resistance to corrosion make aluminum an excellent material for wrapping, lining and cooking foods. Minuscule amounts of alloying elements like magnesium enhance workability without compromising food safety.

The ultrathin yet durable nature of the roll allows it to conform tightly to foods for effective sealing and barrier protection against air, moisture, flavors and contaminants - prolonging freshness during storage.

Its heat conductivity evenly distributes temperature for uniform and consistent cooking results whether using plain foil or formed into bakeware. The nonstick surface also simplifies cleaning.

Aluminum Foil Coil 8011 Applications

Given its food-safe credentials and performance characteristics, food grade aluminum rolls find diverse culinary applications:

Food Storage - Wrapping foods maintains freshness in fridge or freezer by creating an impermeable barrier. Meats, cheeses, baked goods are securely sealed.

Cooking - Lining baking sheets or shaping into trays for roasting vegetables and meats ensures even cooking from oven's heat circulation through foil.

Barbecuing - Foil packets are ideal for grilling delicate fish or making individual foil dinners with herbs and sauces.

Food Presentation - Attractive foil wraps or serving pieces present appetizers, breads or baked goods in a shiny, sanitary manner.

Catering - Foil sheets are suitable for wrapping bulk or homemade food items being transported for events. They can also serve as disposable plates.

Restaurants - Commonly used to wrap takeout boxes, burritos or fast food in a hygienic, tamper-proof manner.

Food Premises - Lining counters, shelves, or equipment provides a disposable non-porous surface ideal for commercial settings.

.jpg)

Aluminum Foil Coil 8011 Purchasing Considerations

When buying aluminum foil roll 8011 for food use, there are a few attributes to assess for ensuring suitability:

Source - Reputable brands with established food safety certifications should be preferred over no-name varieties of unknown quality.

Thickness - Standard gauges for food applications range between 0.0016-0.0021 inches. Thinner gauges may tear while thicker ones lose flexibility.

Surface Quality - Foil should have a lustrous, non-porous surface free of defects like holes, creases or dull patches which could harbor bacteria.

Packaging - Protective sealed wrappers maintain product freshness and hygiene by preventing accidental tears or dents during transport.

Cost - Price per roll or sheet should factor in the product's food safety credentials along with longevity of use before its value determination.

Storage - Maintain unused rolls in cool dry locations away from hazards like moisture, rodents, extreme heat or cold as per manufacturers' guidelines.

Cost-Effectively Versatile

Despite its ultra-thin nature, food grade aluminum roll 8011 remains very durable and capable of multiple uses before requiring disposal. Its recyclability also makes it eco-friendly.

Whether used to wrap single servings or seal bulk homemade or processed foods, its affordability allows cost-saving applications across both domestic and commercial sectors on a large scale.

Considering factors like high performance, versatility across recipes, cuisines and facilities over an easily manageable shelf life - aluminum foil's value far exceeds its nominal material cost, cementing it as a versatile food packaging and preparation staple.

Health and Safety

When utilized responsibly and in moderation as intended, premium food grade aluminum foil rolls pose negligible health risks:

Composition beneath FDA limits for direct food contact ensure safety in recommended applications.

Hygienic, non-porous surface resists bacteria growth - reducing cross-contamination risks compared to reusing other materials.

Risk of leaching aluminum into acidic foods like tomatoes is negligible for intended short-term use and within limits.

Allergies to aluminum are exceptionally rare when meeting purity specifications.

However, those with known sensitivities may avoid aluminum as a precaution. Also, punctures allow direct contact with untreated metal best prevented through proper use and handling. As with any food packaging, good hygienic practices must be followed.

Regulatory Standards

International regulatory bodies maintain rigorous standards for aluminum rolls intended for wrapping edibles to ensure consumer safety. These include:

FDA Food Contact Substance Notification - Certifies aluminum meets purity thresholds for incidental food contact use.

EU Food Contact Materials Regulation - Restricts specific substances in plastic packaging materials also applicable to aluminum foils and paperboard coatings.

BfR Recommendations (Germany) - Provides recommendations on food contact materials to protect public health within the EU single market.

Leading manufacturers submit their aluminum foil products for certification and routine testing by accredited third party labs to comply with and sometimes exceed the thresholds set by major global health authorities. This provides assurance to purchasers and users.

Conclusion

The versatility, performance, affordability and assured safety profile of premium grade food contact compliant aluminum rolls 8011 cements their merit as an indispensable tool worldwide for food packaging, cooking and storage applications across both small and large scales. With proper quality sourcing and hygienic handling practices, their usage delivers enduring value and peace of mind.