Lightweight and disposable, aluminum foil containers are available in a range of shapes and sizes for food packaging. Aluminum pots, takeaway lunch boxes, squares, and cylindrical shapes are among them. Its usual weight ranges from 1.6 to 100g. Because they are practical and efficient, these container designs provide a reliable method of preparing, serving, and storing food.

The composition of the metal affects the advantages of aluminium silver foil container. To begin with, aluminum foil is robust and rip-resistant, guaranteeing that the container will keep its integrity and form while handling. Aluminum foil is a great option for catering and takeaway since it's portable and lightweight, which lowers transportation expenses.

The composition of the metal determines the advantages of aluminum foil containers. To begin with, aluminum foil is robust and rip-resistant, guaranteeing that the container will keep its integrity and form while handling. Aluminum foil is a great option for catering and takeaway since it's portable and lightweight, which lowers transportation expenses.

Aluminum foil take out containers typically hold between 20 to 1800 milliliters, however there are many different types. The features and applications of 450ml and aluminium foil container 250ml will be the main topics of this essay.

In the food service sector, the aluminium foil container 450ml is a common option. 48 mm is the usual height of the container, 150 mm is the mouth diameter, 105 mm is the bottom diameter, 60 mm is the thickness, and the weight is 4 g. It is ideal for keeping essential foods like pasta, rice, and curries so that patrons may dine comfortably, and its medium size makes it appropriate for a number of uses, including the takeaway sector.

In the food service sector, the aluminium foil container 450ml is a common option. 48 mm is the usual height of the container, 150 mm is the mouth diameter, 105 mm is the bottom diameter, 60 mm is the thickness, and the weight is 4 g. It is ideal for keeping essential foods like pasta, rice, and curries so that patrons may dine comfortably, and its medium size makes it appropriate for a number of uses, including the takeaway sector.The 450ml capacity is ideal for portion management for food and catering sector suppliers, guaranteeing that the serving size is appropriate for patrons while reducing food waste. In order to serve lasagna and casseroles straight from the oven, many restaurants prepare them in aluminium foil containers 450ml. Because aluminum has a high melting point, it may be used to partially heat food in an oven.

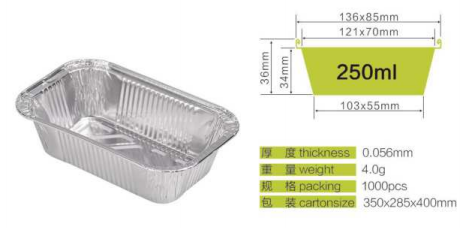

Another popular choice, particularly for smaller amounts, are 250 ml aluminum foil containers, which are frequently appropriate for desserts and side dishes.

Another popular choice, particularly for smaller amounts, are 250 ml aluminum foil containers, which are frequently appropriate for desserts and side dishes.Usually 45 mm tall, 120 mm in diameter at the mouth of the container, and 88 mm at the bottom, this size weighs 4 g and is 60 mm thick. It's ideal for serving side dishes, snacks, and desserts like puddings and tarts. Because smaller portions are more economical, businesses could provide them at a lower rate.

For food preparation for camping, outdoor activities, and other events, these 250ml containers are perfect. They enable customers to separate snacks or side dishes for convenient access throughout the week. For takeout and delivery, a lot of cafes and restaurants employ aluminum foil packaging. They are perfect for a range of menu items, including pizza and salads, because of their capacity to retain temperature and freshness.

Aluminium silver foil container are a good option for food trucks since they are strong and lightweight. Food trucks can deliver hot meals more quickly and effectively with these aluminium foil container 250ml to 450ml containers while requiring less cleaning. Customers also use aluminum foil take out containers for leftovers, baking, and meal preparation at home. They offer a useful method of food storage without the possibility of taste or odor transmission.

One of the top producers of aluminum foil containers, HTMM, is renowned for its excellent goods and productive manufacturing techniques. Method of Production

Choosing high-quality aluminum foil is the first step. The width and thickness of the aluminum foil are modified in accordance with the customer's requirements and the measurements of our own manufacturing machinery.

As our raw material, we select aluminum foil that has third-party quality inspection certificates from organizations like the FDA, SVHC, and European Union. These certifications attest to the raw materials' compliance with food grade standards. To guarantee that the containers are safe to handle food, HTMM only uses food-grade aluminum that satisfies international safety requirements.

After the aluminum foil has been selected, these rolls are fed into the machine to be shaped into containers. Using the right mold and machine stamping, the shaped lunch box is created. Aluminum foil may be formed into a number of forms, including square, rectangular, or circular containers, depending on the mold that is chosen. Once built, the sides of the container are sealed to create a safe environment for food storage.

Quality control is a crucial component of the production process at HTMM. To make sure they fulfill the requirements for strength, durability, and safety, every batch of containers is put through a thorough testing process. The foil containers are packed for delivery after passing quality control inspection.

To guarantee that the containers are packed firmly to avoid damage during transit, HTMM employs corrugated boxes. Aluminum can be recycled, therefore using foil containers is good for the environment. By encouraging recycling and adopting environmentally friendly packaging for their products, HTMM supports sustainable practices.

Even after constant recycling, aluminum maintains its properties. Foil containers are an environmentally friendly choice since they reduce the amount of waste that ends up in landfills because they can be recycled after use. HTMM is committed to using production techniques that are ecologically friendly. The factory uses energy-efficient methods to cut down on industrial waste, which lowers its carbon impact.

Food can be packed and stored in aluminium silver foil container, including 450 ml and 250 ml sizes, for a number of reasons. The food service industry uses foil containers extensively because of its strength, portability, and excellent barrier properties. Furthermore, because of HTMM's efficient production process, these containers will meet strict quality standards while promoting sustainable growth.

Aluminum foil containers provide a flexible answer to your food packaging requirements, regardless of whether you work as a caterer, restaurant, or home chef. These containers are a crucial part of contemporary food service since they can maintain the food's freshness and quality.