Aluminum foil roll 3003-H24 is a cost-effective and adaptable material used in food container production. It is the best option for preserving and safeguarding food because of its important characteristics, which include high purity, excellent barrier qualities, strong thermal conductivity, and recyclability. For take-out containers, baking and grilling, freezing and storing, catering, or gatherings, 3003 aluminum foil rolls are a dependable way to guarantee food quality and freshness. Take advantage of the benefits that come with employing 3003-H24 aluminum foil roll for your food packaging needs.

Aluminum is the primary ingredient in the premium alloy 3003-H24 aluminum foil, with a tiny amount of manganese and other alloying components added. The foil has improved in strength, formability, and flatness by a process of strain hardening and partial annealing, as shown by the H24 temper mark. With a blend of strength, flexibility, and corrosion resistance, 3003-H24 aluminum foil is the recommended material for food container applications due to its unique alloy and temper combination. Aluminum foil alloys 8011, 3003, 8006, alloy state O state, H22, H24, and so forth are available to consumers. 3003-H24 is our best-selling alloy state. since the surface state of the 3003 alloy resists corrosion better than that of the 8011 surface state. Compared to the H22 state, the H24 state is softer.

The following cost considerations are where the benefits of 3003-H24 aluminum foil for food containers are most evident. First of all, food freshness and integrity may be guaranteed by the superior barrier qualities of 3003-H24 aluminum foil, which can keep out light, moisture, oxygen, and other pollutants. Food packaging is shielded from the elements by aluminum foil, which maintains food safety and quality. Second, the H24 temper of 3003 aluminum foil improves its formability and processability for creating stamped aluminum foil lunch boxes, making it simple to form, fold, and seal throughout the food container production process.

Aluminum foil is easily molded into a wide range of sizes and forms without losing its functionality or integrity. Additionally, the 3003-H24 aluminum foil has exceptional heat resistance, rendering it appropriate for use in both conventional and microwave ovens. Aluminum foil ensures effective and safe food packaging by retaining its barrier qualities and structural integrity even at high temperatures.

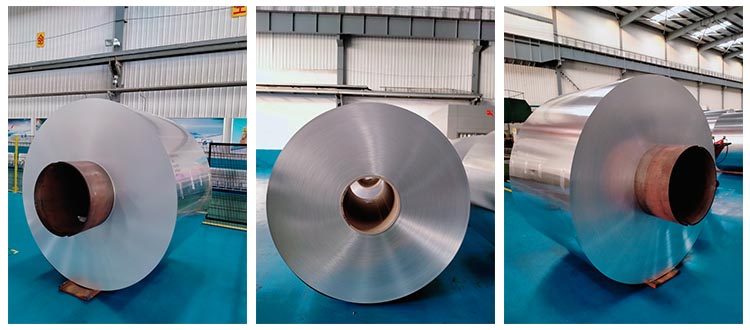

At our factory (HTMM), a number of precise manufacturing procedures are used in the production of 3003-H24 aluminum foil for food containers in order to guarantee quality, uniformity, and performance. Among the crucial phases in the manufacturing process are: Prior to being cast into slabs or billets for additional processing, high-purity aluminum ingots and alloying elements—including manganese—are melted in a furnace. Using specialized rolling mills, the cast billets are hot rolled into thin-gauge coils or sheets. The aluminum alloy's mechanical characteristics are improved and its thickness is decreased during the hot rolling process. To further increase surface smoothness and minimize thickness, the hot rolled aluminum coil is cold rolled. The aluminum foil is subsequently strengthened and made more formable by applying the H24 tempering process.

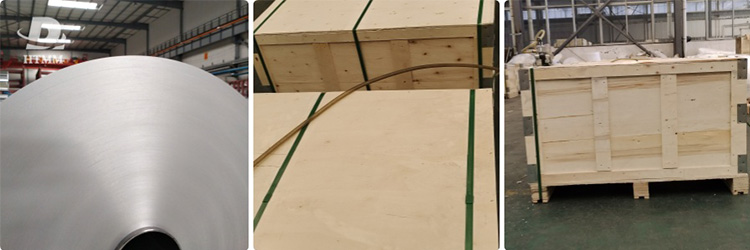

Our rolling mill employs the HONEYWELL thickness control system and the ABB plate control system throughout the rolling process to guarantee that clients may get aluminum foil in a variety of thicknesses throughout the rolling process. Using a precise slitting machine, the cold-rolled aluminum foil coil is cut to the desired width and length. To ensure that the aluminum foil satisfies quality criteria for use in food packaging applications, it is cleaned, surface treated, and inspected. We must lube and coat the 3003-H24 aluminum foil in order to increase its formability and barrier qualities because the customer's machine may not always have an oiling function. Aluminum foil can have food-grade coatings added to its surface to improve its performance in food packaging applications.

In the food container business, 3003-H24 aluminum foil is frequently used to package a range of items, such as baked goods, snacks, chocolates, dairy products, and ready-to-eat meals. Aluminum foil is used to manufacture packaging, trays, lids, and disposable containers that are hygienic, convenient, and safe for food. Aluminum foil with the formability, barrier, and heat resistance of 3003-H24 is a great option for food packaging applications that need freshness, safety, and durability.

Our 3003-H24 Aluminum Foil for Food Containers manufacturers adhere to strict quality control measures and industry standards to ensure product excellence and compliance with food safety regulations. Our (HTMM) products have third-party quality inspection certificates such as Europe, the United States, SVHC, etc. These certificates can prove that our aluminum foil can be well contacted with food, and our aluminum foil quality fully complies with the best food grade aluminum foil.

It can protect the health of food while protecting the aluminum foil from harming your body. And our aluminum foil undergoes rigorous thickness, strength, formability and barrier tests to meet the requirements of food packaging applications. In addition, HTMM as a manufacturer adheres to international standards such as FDA regulations and European Food Contact Directives to ensure the safety and suitability of 3003 aluminum foil for food contact purposes. And the edible oil we apply on the surface of the aluminum foil also has FDA inspection certificates. Our products fully comply with FDA regulations and European Food Contact Directives.

In the food packaging sector, 3003-H24 Aluminum Foil for Food Containers is the epitome of production excellence, quality control, and performance. The alloy is a great option for packaging a wide range of foods because to its exceptional qualities, which include barrier protection, formability, heat resistance, and recyclability. The 3003-H24 aluminum foil satisfies the demands of the food container industry by means of precise production methods, stringent quality control, and adherence to food safety requirements. This results in packaging solutions that are safe, effective, and environmentally friendly for both makers and customers.