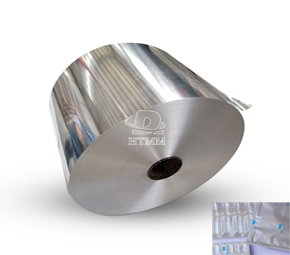

Aluminum foil is a hot stamping material which is directly calendered into a thin sheet of metal aluminum. Its hot stamping effect is similar to that of pure silver foil stamping, so it is also called fake silver foil. Since aluminum has a soft texture and good ductility, it has a silvery white luster. If the calendered sheet is smashed on an offset paper with a material such as sodium silicate, an aluminum foil sheet can be formed. However, the aluminum foil itself is easily oxidized and the color is darkened, and friction, touch, and the like are discolored, and thus it is not suitable for hot stamping of a book cover that has been preserved for a long time. Aluminum foil can be divided into thick foil, single zero foil and double zero foil according to the thickness difference.

Double zero aluminum foil is relatively thin, mainly used in the packaging industry, such as food packaging, cigarette packaging and so on.