Aluminum foil is a versatile material that plays a vital role in packaging, food, pharmaceutical and other industries. As the demand for cost-effective solutions continues to grow, competitively priced aluminum foil manufacturing has become crucial for businesses. This article will take you through the aluminum foil manufacturing process at our aluminum foil mill (HTMM), the factors that influence price competition and the benefits it brings to different industries.

We (HTMM) Aluminum were established in 2009. Through more than 15 years of development in China and abroad, we have developed into a leading diversified aluminum product manufacturer in China. Our factory is located in Binzhou City, Shandong Province and has very rich experience in aluminum rolling and processing. We have exported our products to more than 70 countries, served more than 3,500 customers, and once received praise from customers for the quality of our products. Our best-selling products include household aluminum foil, Food container aluminum foil, aluminum foil for lamination, as well as industrial foil, heat sealing foil and food container foil.

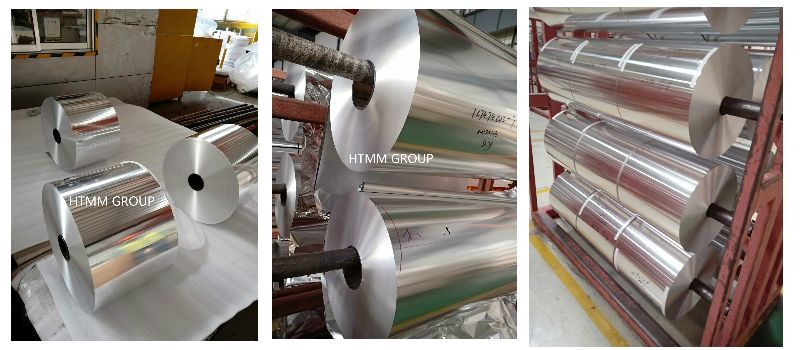

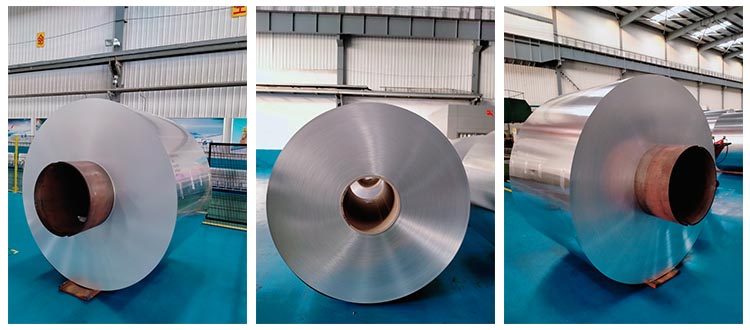

HTMM Aluminum Foil factory has the most advanced production lines and cutting-edge technology, with an annual output of more than 80 million tons. We strictly adhere to international quality standards such as ISO 9001 to ensure the reliability of the quality of our products. After receiving the customer's order, our factory will go through aluminum ingot processing, rolling, cooling, annealing, cooling and other processes. In the rolling process, our rolling mill adopts HONEYWELL thickness control system and ABB plate control system, which can ensure that the entire rolling process can provide customers with aluminum foil of different thicknesses.

Making aluminum foil in our factory (HTMM) involves many production processes. The key steps of the process include melt casting, hot rolling, cold rolling, annealing, finishing and other steps.

HTMM will first choose aluminum ingots with a purity of 99.9% as our raw materials. Start with an aluminum ingot being melted in a furnace. The molten aluminum is then cast into large rolls called billets. These blank rolls are the raw material for the production of aluminum foil. Each of our blank rolls can produce approximately 5 to 8 tons of aluminum foil. The billet coil passes through a series of rolling mills that gradually reduce the thickness of the aluminum. This process, called hot rolling, involves applying high pressure to a roll of billet to elongate it and reduce its thickness. The blank roll is reheated in between to maintain its ductility.

After the hot rolling process, the aluminum strip enters the cold rolling stage. Cold rolling further reduces the thickness of the aluminum and gives the foil the desired surface finish. The strip is passed through a series of rolling mills at room temperature, which compresses and elongates the aluminum while maintaining its thickness uniformity. The cold rolled aluminum strip is then annealed. Annealing involves heating the foil to a specific temperature and then slowly cooling it. This process helps relieve internal stresses and increases the flexibility and ductility of the foil. Annealing also improves the final mechanical properties and surface quality of the foil. The foil is trimmed, cut and packaged according to customer requirements. If required for a specific application, the foil can receive additional treatments such as surface cleaning or coating. The finished foil is then rolled into large spools or cut into smaller rolls or sheets for distribution and use in various industries.

There are many factors that affect the competitiveness of aluminum foil manufacturing pricing. Aluminum ingots are the main raw material for foil manufacturing, and their costs have a great impact on pricing. Fluctuations in aluminum prices can affect overall production costs and, in turn, the competitive pricing of aluminum foil. Therefore, the price of aluminum foil will change with the change of aluminum ingot price. Efficient manufacturing processes and streamlined operations contribute to competitive pricing. Foil manufacturers that optimize their production processes and reduce waste can offer more competitive prices. To our large aluminum foil mill (HTMM) Large aluminum foil manufacturers benefit from economies of scale and we are able to spread fixed costs over higher production volumes. This saves costs and passes them on to customers in the form of competitive prices. We have been continuously increasing investment in advanced technology and innovation to improve production efficiency and reduce costs. Aluminum foil manufacturers that embrace technological advancement can achieve competitive prices by increasing productivity and reducing energy consumption. And effective supply chain management, including raw material procurement, logistics and warehousing, plays a vital role in cost optimization. We have a well-managed supply chain, from raw material procurement to delivery to customers. We can reduce costs and provide competitive prices.

Good price aluminum foil brings many benefits to different industries. The packaging industry relies heavily on aluminum foil for its excellent barrier properties. The competitive pricing of aluminum foil manufacturing benefits the packaging industry by providing cost-effective solutions for various applications such as food packaging, pharmaceutical blister packaging and cosmetic packaging. Competitive pricing enables food manufacturers to purchase aluminum foil at affordable prices. Aluminum foil is widely used for packaging, cooking and preserving food due to its moisture resistance, thermal conductivity and barrier properties. Competitive pricing enables food manufacturers to maintain product quality while minimizing packaging costs. The pharmaceutical industry relies on aluminum foil to package pharmaceuticals and medical devices. Competitive pricing for aluminum foil manufacturing ensures pharmaceutical companies get high quality aluminum foil at a reasonable price. This allows them to comply with strict regulations while controlling packaging costs. Competitive prices for aluminum foil manufacturing benefit the HVAC and insulation industries. Aluminum foil acts as an insulating reflective barrier, reducing heat transfer and energy consumption. Affordable foil prices enable HVAC and insulation manufacturers to provide cost-effective solutions for residential, commercial and industrial applications. The electronics industry uses aluminum foil for shielding, heat dissipation and insulation purposes. Competitively priced aluminum foil has many different benefits for many industries.

Good price aluminum foil manufacturing is essential to meet the needs of various industries. The complexity of the aluminum foil manufacturing process, coupled with factors such as raw material costs, operational efficiency, economies of scale, technology and supply chain management, results in competitive pricing. Businesses in the packaging, food, pharmaceutical, HVAC, insulation and electronics industries benefit from competitive pricing by getting high-quality aluminum foil at affordable prices. As the demand for cost-effective solutions continues to grow, competitively priced aluminum foil manufacturing remains an important aspect of the manufacturing process.