.jpg) The quality of food and operational efficiency in the cooking and food service sectors can be greatly impacted by the materials used. Commercial heavy-duty aluminum foil is a useful and essential tool among these materials. With an emphasis on the heavy-duty kind, this post will walk you through the benefits, uses, costs, and manufacturing process of commercial aluminum foil at our HTMM facility.

The quality of food and operational efficiency in the cooking and food service sectors can be greatly impacted by the materials used. Commercial heavy-duty aluminum foil is a useful and essential tool among these materials. With an emphasis on the heavy-duty kind, this post will walk you through the benefits, uses, costs, and manufacturing process of commercial aluminum foil at our HTMM facility.Commercial aluminum foil is made for use in food processing, food service, and professional kitchens. The commercial version is thicker and tougher than laminated aluminum foil, which makes it perfect for barbecues, catering businesses, and residential kitchens, among other uses. For a range of culinary and storage applications, this commercial heavy-duty aluminum foil is superior because to its exceptional strength and longevity.

Strong aluminum foil is resistant to ripping and can tolerate high temperatures. Because of its thickness, it can withstand harsh conditions and is frequently used for covering dishes, lining baking pans, and wrapping food. Baking, grilling, roasting, and food storage are just a few of the uses for sturdy aluminum foil. Because of its shape-adaptability, a wide range of meals may be wrapped and covered with ease. Because of this, heavy-duty aluminum foil is essential for food makers, caterers, and restaurants.

In terms of food safety, our commercial heavy-duty aluminum foil raw materials use aluminum ingots with an aluminum content of 99%, and our (HTMM) aluminum foil products and paint materials have third-party quality inspection certificates such as European and American FDA, SVHC, etc.

These certifications may attest to the fact that our aluminum foil is completely compatible with high-quality food-grade aluminum foil and that it can come into good contact with food. In addition to preventing aluminum foil from harming your body, it may preserve the nutritional value of food. When used properly, our industrial aluminum foil ensures that no dangerous chemicals will seep into food and may be used safely for both cooking and food storage.

Commercial Heavy Duty Aluminum Foil Price

Customers frequently inquire about our production cost structure when they are thinking about purchasing industrial heavy-duty aluminum foil. Customers frequently care about this issue. The price of the raw materials, thickness, and quantity of purchase all affect how much our heavy-duty aluminum foil price. The cost of buying raw materials for aluminum ingot has the most impact on the aluminum foil price per kg.

We provide customers with different quotations for heavy-duty aluminum foil at different times since the price of the raw materials for aluminum ingot is frequently fluctuating. Second, our production expenses have an impact as well. More rolling procedures will be needed to produce thinner aluminum foil, which will increase production costs.

Third, each plant has a minimum order quantity since every client has distinct requirements for heavy-duty aluminum foil. Our rates will be higher than the cost of buying in bulk since the mother rolls we make can create around 6 to 8 tons of aluminum foil for clients when they purchase smaller amounts (minimum order quantity: 3 tons).

Price dynamics are influenced by market trends, factors, and the growing demand for food packaging, particularly in the delivery and takeout sectors.

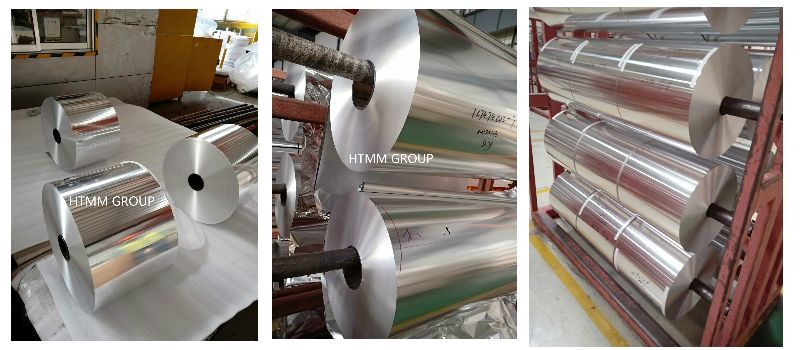

HTMM Factory Production Process

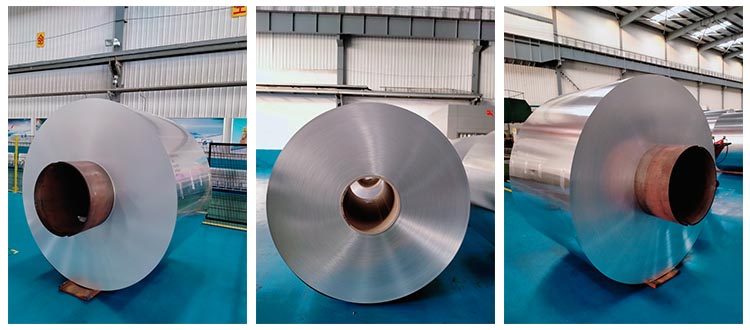

One of the top producers of aluminum foil goods, including commercial heavy-duty aluminum foil, is HTMM. Our facility, which produces over 80 million tons a year, has the most sophisticated manufacturing lines and state-of-the-art equipment. To guarantee the dependability of our product quality, we rigorously adhere to international quality standards like ISO 9001. Following customer orders, our factory will process, roll, cool, anneal, and cool aluminum ingots, among other procedures.

Our rolling mill's HONEYWELL thickness control system and ABB plate control system are used in the rolling process to guarantee that clients receive varying thicknesses of aluminum foil throughout the rolling process. Additionally, we will use sampling techniques to evaluate the quality of each batch of consumers' items. Our devoted research and development team is dedicated to ongoing product innovation and personalized solutions. Another fundamental principle in our quest for environmentally friendly operations is sustainability.

HTMM begins with premium aluminum ingots that adhere to industry norms. The molten aluminum is formed into big slabs after the ingots are melted in a furnace. In order to shape the aluminum into a shape that can later be rolled into foil, this first step is essential. The aluminum sheet undergoes a number of rolling procedures after cooling and solidifying. The slab progressively loses thickness as it travels past heavy rollers.

This step is critical to creating the required thickness for heavy-duty foil. After rolling, the foil is annealed to relieve internal stress and increase its flexibility. The process involves heating the foil to a specific temperature and then cooling it, ensuring that it maintains its strength without becoming brittle.

We then cut the rolled aluminum foil into various widths according to the width required by the customer to meet the needs of different customers. Finally, we package it, and we use international standard export fumigation-free wooden packaging boxes.

Here are the questions clients usually ask:

1.Q: Can your products be in direct contact with food?

A: Our products can be in direct contact with food, and our products have FDA, SVHC, EUROHS and other certificates to prove that our products meet your requirements

2.Q: Can foil size be customized?

A: Yes, we can customize foil size for customers

3.Q: What is your minimum order quantity?

A: Normally, we require a minimum order quantity of 3 tons. In special cases, we will provide additional instructions.

4.Q: Do you provide free samples rolls?

A: Currently, if you ask us to provide samples, you need to pay for the samples and shipping.

5.Q: How to get a quote?

A: Your detailed size requirements for the havy duty foil , including thickness, width ,and your order quantity. We would be grateful if you would like to know more about our quotation.

6.Q: What transaction method do you use?

A: Usually we accept FOB. Your preferred transaction method will also be considered.

Commercial heavy-duty aluminum foil is an essential tool for any professional kitchen, combining durability, versatility and safety. From baking to grilling and food storage, this aluminum foil can be used in a variety of cooking applications.

At HTMM, we're dedicated to creating premium aluminum foil goods that satisfy our clients' various demands. Every roll of heavy-duty aluminum foil is dependable and prepared for any culinary challenge thanks to our painstaking production process.