Advantage of Aluminum Container Foil

Our (HTMM) Food container foil is non-toxic and odorless, making it a safe choice for direct contact with food. Aluminum foil containers can be easily disposed of after use, minimizing the risk of cross-contamination and maintaining appropriate hygiene standards. Aluminum foil containers are lightweight and easy to carry, making them convenient for food suppliers and consumers. Compared to other packaging materials, aluminum foil containers are relatively inexpensive, making them an economical choice for the food industry. And aluminum foil rolls can be customized into a variety of shapes and sizes to meet the needs of different food packaging.

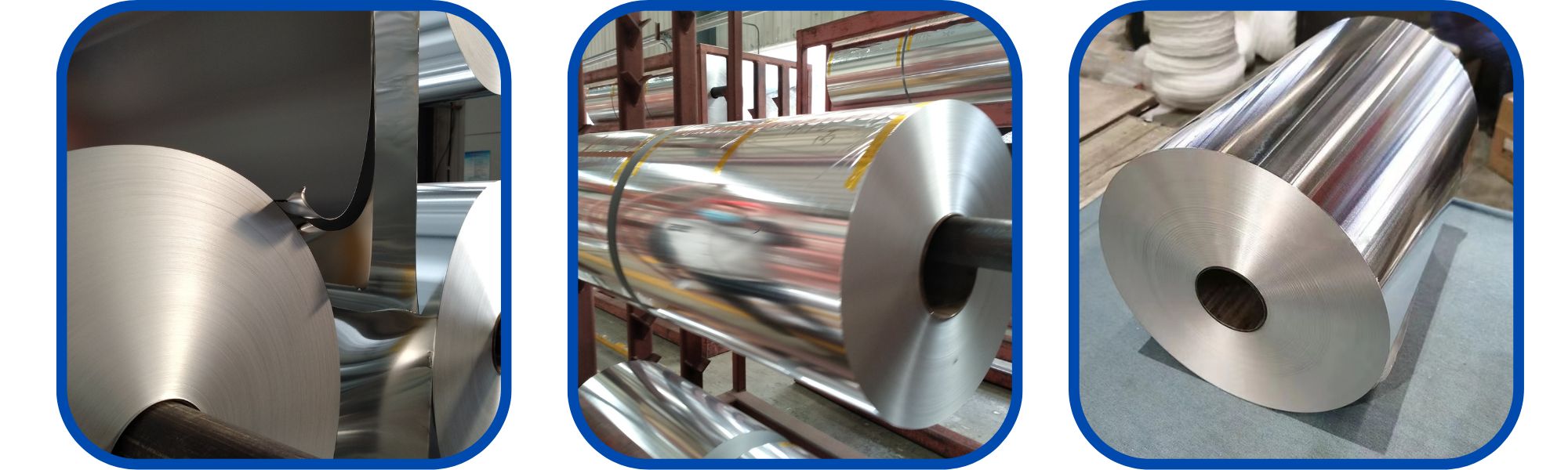

Rolls of Aluminum Foil are a useful and effective material to use for making food containers. It's the perfect material for food preservation and protection because of its high purity, excellent barrier qualities, strong thermal conductivity, and recyclability. Aluminum foil rolls are a dependable way to guarantee food quality and freshness whether it's for catering or events, baking and grilling, freezing, or takeout containers.

| Product Name | Aluminum Foil Raw Material Jumbo Rolls For Containers |

| Material | Aluminum foil raw materails |

| Temper | H22 H24 |

| Thickness | 0.03 mm-0.15mm |

| Width | 50-1500 mm |

| Coil ID | 76mm,152 mm |

| Coil Weight | 80-150 kg |

| MOQ | 3 Ton |

| Delivery time | 30 days after 30% T/T payment or receiving L/C copy |

| Application | Food package,household use flexible package, making food container , |

The fundamental component of the food container industry, aluminum rolls serve as the foundation for producing a wide range of shapes and sizes of containers. These are big, continuous rolls of aluminum foil that are typically made in a range of thicknesses appropriate for food packaging. Oiled container foil rolls are another service we can provide clients as we can tailor the thickness, breadth, alloy state utilized, quantity, etc. to suit their needs. Serving over 3,500 clients, we have exported our goods to over 70 countries and have earned positive feedback for the caliber of our offerings from them.

How to Choose Lubricated Aluminum Foil and Non-Lubricated Aluminum Foil

Al Foil for lunch boxes is one of our best-selling items. In addition, we are able to offer an assortment of colored and painted metal foils. The surface might be translucent, dark green, blue, pink, gold, or white, for instance. The majority of applications for these colored-coated aluminum foils are in lunch box manufacturing. The primary use cases include lunch boxes for airplanes, outer packing for gifts of holiday food, etc. Aluminum coils may be used as a blank canvas to create a range of food containers, including disposable trays and takeout boxes, at any time.

Because aluminum coils function better than other materials, food container producers choose to utilize them. In order to achieve the necessary thickness, breadth, and other parameters, aluminum container makers first choose appropriate aluminum foil rolls, such as 3003 alloy, throughout the production process. Feed into the forming machine, the pre-treated and lubricated aluminum foil is formed into the required container design through a series of mechanical operations. The bottom, sidewalls, and edges of the container are formed by the forming machine using a mix of heat, pressure, and molds.

Manufacturers of aluminum lunch boxes may get oiled or unoiled container foil from us at HTMM. Whether or whether the client's machine has oiling equipment will determine this primarily; if it does, the customer can buy unoiled container foil right away. Aluminum is very ductile, which makes it easy to mold and ideal for creating a variety of sized and shaped containers. Aluminum's low weight also guarantees that the finished container will be simple to handle, carry, and store.

The quality, safety, and freshness of packaged goods are significantly enhanced by the use of aluminum foil for food containers, which is made from aluminum coils. Aluminum foil for food containers may be used in ovens and microwaves since it is made specifically to resist high temperatures. This eliminates the need for extra plates or silverware by enabling customers to easily reheat meals right in the container. Among its many benefits is aluminum foil's ability to efficiently keep out light, moisture, and oxygen when used to manufacture food containers. This barrier prolongs the shelf life of food by preserving its flavor, fragrance, and texture. Aluminum foil also serves as a barrier against outside impurities, guaranteeing that food is kept clean and safe while being transported and stored.

Related Applications of Aluminum Foil Raw Materials Jumbo Roll

Aluminum foil is essential to many facets of food packaging, not only the creation of food containers. Aluminum foil is incredibly convenient and versatile; it can be used for anything from sealing food bags and trays to wrapping sandwiches and leftovers. Because of its elasticity, aluminum foil may take on the shape of food, creating an airtight and safe seal. This keeps packaged food fresher longer and helps protect its quality. It also helps avoid leakage.

Furthermore, aluminum foil is simple to print on or emboss, offering customers chances for branding and labeling, improving product appearance, and conveying crucial information. There are more applications for aluminum foil in food packaging than just keeping food fresh. In addition, it has a number of useful features including heat resistance, which lets you cook or reheat food right in the foil, cutting down on the amount of extra cookware you need, and less cleaning. Aluminum foil is a fantastic option for keeping leftovers or cooked meals because it can be frozen.

The food packaging sector has undergone a transformation with the introduction of aluminum foil stock rolls. Their exceptional ductility and simple formability serve as the foundation for the production of a broad variety of food containers. The resulting food storage, transportation, and reheating containers are practical, adaptable, and easy to use.

Food Container Foil is made from aluminum rolls and serves as a barrier against pollutants, moisture, and air to maintain freshness, safety, and quality. It may be used in microwaves and ovens, doing away with the need for extra cookware. The advantages of aluminum foil for food packaging may be used to many other tasks, such as labeling, wrapping, and sealing, which improves the entire appearance and experience for the customer.

The usage of aluminum foil stock rolls in food containers has led to a significant change in the food packaging sector. When aluminum foil is used for its many uses, food that has been wrapped stays safe, fresh, and of the greatest caliber. Because of its practicality and ease of use, aluminum foil is now a necessary ingredient for food packaging and preservation, satisfying changing customer demands and boosting industry success.