Aluminum Foil Price Comparison: Which Brand Offers the Best Value?

Aluminum Foil Price Comparison: Which Brand Offers the Best Value?Company Profile:

The company is a leading enterprise in the domestic aluminum sheet processing industry. HTMM was founded in 2009 and is headquartered in Anyang, Henan. It is a private enterprise based on new material technology for the production and sale of the aluminum processing industry. R&D, production and sales of noodles and its deep processed products.

Introduction of aluminum foil:

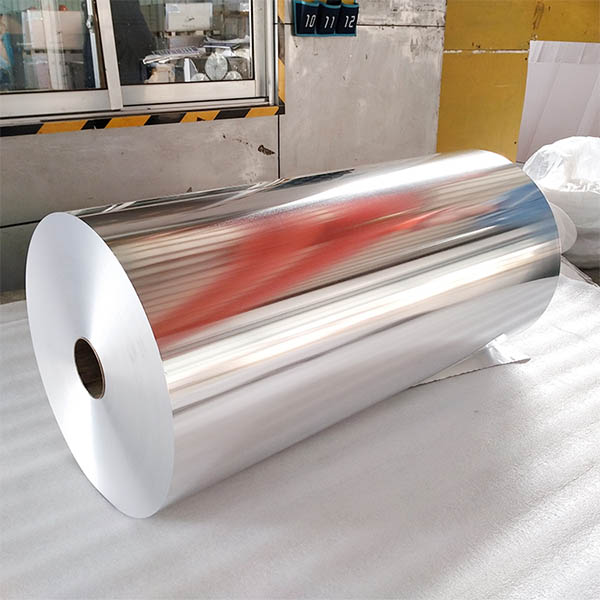

Aluminum Foil is a type of rolled aluminum material. Alu products with a thickness of less than 0.2 mm are usually called foil. It is mainly used in packaging, home appliances, electronic communications, transportation, printing, chemicals, building materials, decoration and other industries. It is the aluminum product with the most elaborate procedures, the smallest thickness and the most difficult. Aluminum foil can be divided into four main types according to application: packaging paper, air conditioner paper, electronic paper, and battery paper. Driven by demand, aluminum foil has entered a high economic cycle. In 2021, the production of aluminum processing materials will be 39.53 million tons, year on year +5.8%. Among them, the total output of aluminum foil was 4.55 million tons, compared to only 2.52 million tons in 2012, with an average annual compound growth rate of 6.8%, much higher than the average growth rate of the rolling industry of aluminum. Recently, the demand for packaging foil, electronic foil and battery foil is high, and the processing fee of aluminum foil has increased several times in the first half of the year. The resonance of multiple factors has caused the aluminum foil to become more tense. link in the supply and demand of the entire aluminum processing industry. As of March 2020, the operation rate of aluminum foil has continued to be higher than 80%, and the highest has even reached 88%. So far, the listed companies are planning to expand their production of aluminum sheets, strips and sheets. There are a total of 16 projects under construction, of which 13 include battery aluminum foil projects, focusing on battery aluminum foil, carbon coated aluminum foil, electronic aluminum foil and formed foil.

Aluminium foil roll Price composition:

Aluminium foil roll price adopts the "aluminum ingot price + processing fee" pricing model. Most of the company's sales adopt the direct sales model, and the product price model is "aluminum ingot price + processing fee". The aluminum ingot price is generally the Yangtze River aluminum ingot price one month before delivery, the Shanghai aluminum futures ingot price or the London aluminum ingot price The monthly average price price and the processing fee depend on factors of such as product process, alloy composition and process complexity. The company's internal sales provide customers with more complete communication and information services through regional coverage of key customers and dispatch of business representatives to key market areas. International sales are mainly based on direct sales and are supplemented by distribution. This sales model helps the company integrate the needs of distributed products and expand the scope of sales services. Currently, the company's products have been exported to more than 70 countries and regions such as United States, European Union and Thailand.

The aluminum foil processing process is an aluminum product with the most elaborate procedures, the smallest thickness and the most difficult in the aluminum processing industry. currently

There are two processing routes commonly used in the industry:

(1) the hot rod rolling method; (2) two-turn casting and rolling method.

(1) Ingot hot rolling method: first cast aluminum melt into a flat ingot, and then go through homogenization, hot rolling, cold rolling and intermediate annealing

After the process, continue cold rolling into a plate with a thickness of about 0.4 ~ 1.0 mm as a sheet blank (melting and casting → hot rolling blank → cold rolling → foil rolling).

(2) Two-roll casting and rolling method: Compared with the hot rod rolling method, the production process of aluminum foil blanks by the casting and rolling method is relatively simple

single; you don't need to go through complicated process steps like ingot melting, grinding, homogenizing and hot rolling, but pour the aluminum melt directly.

Two rotating casting rolls (molds) are inserted into the casting and rolling area to complete the two processes of solidification and hot rolling in 2~3 seconds at the same time and get

Take a 4~7mm thick plate. Similar to hot rolled aluminum sheets, cast sheets must also go through a series of cold rolling, intermediate annealing.

The fire process, and finally rolled into the plate 0.3 ~ 0.7 mm thick as blank aluminum sheet.

The equipment of the two-rotation casting and rolling method is simple, the total investment is small, the production cycle is short, and many tedious processes such as grinding, homogenization and hot rolling in the production process of the roll-wrapped plates are hot are set aside. The cost is greatly reduced; however, due to the different cooling methods and thermal processing conditions in the production of plates by the two-roll casting method, the internal structure of the cast plate mainly has shortcomings such as separation, uneven structure. , and coarse grain structure after baking. It is harder, so it is used relatively less in high-quality aluminum foil products.

According to China Nonferrous Metals News, at the end of 2018, there were more than 800 two-roll casting and rolling production lines in China, with an annual production capacity of more than 8 million tons; more than 200 bars production hot rolling lines, with a production capacity of about 20 million tons per year. By 2020, China's continuous two-roll casting and rolling strip production will exceed 8 million tons, and the production of bar-rolled strip will exceed 42 million tons per year. At present, the casting and rolling process applied to aluminum sheet blanks is gradually matured, and more and more enterprises begin to use the casting and rolling process to produce aluminum foils, and casting and rolling has become the main process of the part aluminum front. metal sheet. Throw and spin appeared in the 1970s, and the technology is still not perfect. In recent years, Dingsheng New Materials has independently developed the "green production technology of short cold rolling process" and successfully applied it to high-end products such as double-zero foil and battery foil with electricity. This technology innovates the entire industry chain from composition optimization, melting process, continuous casting and spinning process, cold rolling/rolling process optimization, performance testing and quality control technology, and uses casting and spinning instead of hot rolling to produce aluminum sheet for batteries / energy sheets, which reduces the production cost of aluminum sheets / sheets for energy batteries manufacturers, improves market competition and mainly promotes the development of domestic processing industry of aluminum batteries. After the aluminum foil blank is made, the aluminum foil blank goes through a series of rough rolls, intermediate rolls and final rolls to form foil aluminum of different thicknesses, and then bakes the finished product. In general, thick sheets only need rough turning, single zero sheets need rough turning and intermediate turning, and double zero sheets and other aluminum foils with high precision requirements need turning

HTMM Aluminum foil price advantage:

High quality customer resources, stable production and operation. The company has established good long-term cooperative relationships with many well-known customers. Consistent, high-quality customer sourcing will not only help the company increase its brand awareness, but also expand customer demand in a virtuous circle. time, will help to maintain the overall level of the company's operation. Improving the product quality and service capabilities of the enterprise and increasing the level of risk management and control. Since its establishment, the company has been engaged in the research and development, production and sale of aluminum foil 8011, aluminum household foil and aluminum container foil. It has a wide range of product categories, a wide range of downstream application scenarios and a mature business model. It has established long-term and stable cooperative relationships with many well-known clients. The company is good at seizing market development opportunities, constantly optimizing product structure and gradually developing double zero sheet production lines.

Company advantage:

The company has independent equipment research and development capabilities. The company has been deeply involved in the aluminum sheet business for many years. Through continuous research and study of international advanced equipment, the company has earlier mastered the ability of independent research and development and technical transformation of equipment. With the help and monitoring of the advanced detection system, the company's existing equipment is all manufactured in-house and can be flexibly modified according to the company's advanced design concept, in order to ensure the quality of product production and production efficiency is improved.

Htmm company is a high-tech alu foil production enterprise specializing in the production of aluminum paper foil and aluminum foil paper products. The company's indicators take the first place among enterprises of the same scale in the country. We adhere to strict requirements for high standard management and manufacturing guidance, use first-class equipment, advanced technology and scientific management, and focus on the development, production and sales of aluminum foil products. Products have passed US FDA food safety certification and other testing and ISO9001: 2000 international quality management system certification. The aluminum foil plastic cover produced is exported all over the world.