Aluminum Foil For Food Container

Alloy 3003 and 8011 are a common alloy used in the production of food containers. They belong to 3 series and 8 series aluminum alloys respectively, which are famous for their excellent corrosion resistance and formability. Adding manganese to the alloy composition increases its strength and makes it suitable for a wide range of applications. The corrosion resistance of 3003 alloy aluminum foil is better than that of 8011 alloy. When it comes to lunch boxes, 3003 aluminum foil has become the first choice of customers because of its unique properties. Usually, aluminum lunch box manufacturing factories will choose 3003 alloy, and some customers will choose to use 8011 alloy when they need to produce aluminum lunch boxes with transparent coating. It provides a protective barrier against oxygen, moisture and light, ensuring the freshness and quality of food. Additionally, the foil's heat resistance allows for direct and safe reheating of the container's contents, making it a convenient option for dining out.

Aluminum foil plays a vital role in the production of aluminum food containers. These containers are widely used in restaurants, takeaway services and bakeries and in the food packaging industry. The advantages of using aluminum foil to make lunch boxes are mainly reflected in these aspects. First, aluminum foil has excellent thermal conductivity, distributing heat evenly when the container is used for cooking or reheating food. This feature ensures food is heated evenly, eliminating cold spots and providing a consistent cooking experience. Second, aluminum foil lunch boxes are lightweight and easy to carry and transport. This feature is particularly beneficial for individuals who prefer to package their own meals or have a meal delivery service, as it reduces overall weight and increases convenience. Thirdly its own durability, aluminum foil containers are very durable and able to withstand a variety of temperatures and handling conditions. They resist punctures, tears and other physical damage, ensuring food remains intact during transportation and storage. Moreover, aluminum container manufacturers can create aluminum lunch boxes in a variety of shapes and sizes to meet different food portion sizes and presentation needs. From single-serve containers to larger family-size options, they offer the flexibility to package different types of meals, including salads, entrees and desserts.

| Description | Aluminum Container Foil |

| Material | aluminium Foil Raw Materials |

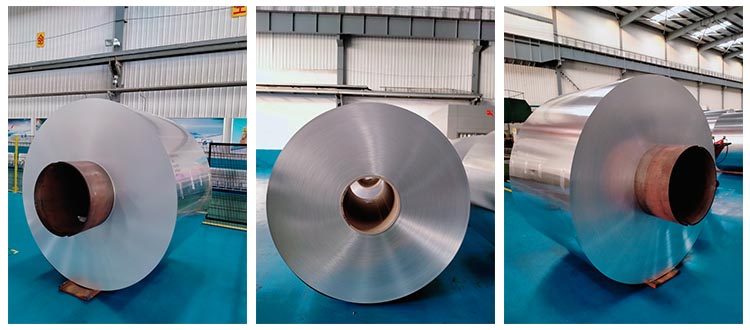

| Shape | Aluminum container foil roll |

| Alloy/temper | 8011 3003 8006/H22 H24 |

| Length | Jumbo roll |

| Usage | food, ketchen packing storing freezing ,etc |

| Core ID | 76mm 152mm |

| Thickness | 0.03-0.15mm |

| Width | 200mm-1600mm |

| Package | Wooden case |

| delivery time | 30days-35days |

| payment | T/T,L/C |

| quality tolerance | >99.5% |

| cerfificate | ISO9001:2000,FDA, EU ROHS , SVHC |

| manufacturer | Henan tendeli metallurgical materials Co., Ltd |

Aluminum Container Foil Production Process

During the production process, aluminum container manufacturers first select suitable aluminum foil rolls, such as 3003 alloy, that meet the required thickness, width and other specifications. We also recommend customers to choose food-grade aluminum foil. Our (HTMM) factory has third-party quality inspection certificates from Europe, the United States, SVHC, etc. These certificates can prove that our aluminum foil can be in good contact with food. The quality of our aluminum foil is fully in line with good food grade aluminum foil. It can protect the health of food while preventing aluminum foil from causing harm to your body.

Aluminum foil rolls are inspected for defects and undergo quality control measures before being used in production. Workers then need to feed and unwind the selected aluminum foil rolls into the production line, where they are unrolled and passed through various rollers and tensioning systems. This step ensures correct alignment and tension control for a smooth production process. During the production process, the aluminum foil must also be lubricated to enhance its formability during the container molding process and prevent the aluminum foil from adhering to the mold. Oiling can increase production efficiency.

The lubricated and pre-treated aluminum foil is fed into the forming machine, where it undergoes a series of mechanical processes to shape it into the desired container design. Forming machines use a combination of pressure, heat and molds to form the structure of the container, including the bottom, side walls and edges. We (HTMM) can provide either oiled or unoiled container foil to aluminum lunch box manufacturing factories. This mainly depends on whether the customer's machine is equipped with oiling equipment; if the customer's machine is equipped with oiling equipment, Oil equipment, then customers can directly purchase container foil without oiling, which will save customers' production costs in the long run.

3003 alloy aluminum foil plays a vital role in the production of aluminum food containers, including lunch boxes. Its unique properties, such as thermal conductivity, lightweight, durability and versatility, make it ideal for packaging meals. As the demand for convenient and sustainable food packaging solutions continues to increase, aluminum foil containers continue to gain popularity in various food service industries and are recognized for their ability to maintain food freshness, provide efficient heating and reheating, and are convenient for portability Widely recognized. As the industry continues to evolve, lunchbox aluminum foil remains a reliable and innovative solution to food packaging needs.

Aluminum Container Foil Provider HTMM

We (HTMM) Aluminum were established in 2009. Through more than 10 years of development in China and abroad, we have developed into a leading diversified aluminum product manufacturer in China. Our factory is located in Binzhou City, Shandong Province and has very rich experience in aluminum rolling and processing. We have exported our products to more than 70 countries, served more than 3,500 customers, and once received praise from customers for the quality of our products. 3003 alloy container foil is one of our best-selling products. We offer a range of aluminum foil items, including wholesale aluminum foil that can be customized at low cost. With customized services in alloy composition, thickness, width, length, surface treatment and packaging, HTMM specializes in providing cost-effective solutions to meet the unique needs of each business. 3003 aluminum foil is non-toxic and odorless, making it a safe choice for direct food contact. Aluminum foil containers can be easily disposed of after use, minimizing the risk of cross-contamination and maintaining proper hygiene standards. Aluminum foil containers are lightweight and portable, making them convenient for both food vendors and consumers. Aluminum foil containers are relatively inexpensive compared to other packaging materials, making them an economical choice for the food industry. 3003 aluminum foil rolls can be customized into various shapes and sizes to meet the needs of different food packaging.