Aluminum foil, a key component of the packaging business, is essential for maintaining freshness and prolonging the shelf life of many food and beverage goods. Assuring the integrity and caliber of packaged items, its superior barrier characteristics guard against air, light, moisture, and contaminants. Aluminum foil offers dependable packaging solutions, from wrapping chocolate and cigarettes to sealing containers of processed food.

When it comes to preserving the freshness and increasing the shelf life of different food and beverage goods, aluminum foil plays a crucial and essential role in the packaging sector. Due to its superior barrier qualities, it is perfect for maintaining the integrity and caliber of packed items.

Aluminum foil's superior barrier qualities are one of its key packaging benefits. It functions as a barrier, successfully obstructing oxygen, light, moisture, and pollutants that could degrade the quality and freshness of the contents. Particularly oxygen can cause food to oxidize and deteriorate, changing its flavor, texture, and nutritional content. The long-lasting freshness and flavor of the goods are preserved by the aluminum foil's impermeability, which prevents oxygen from entering the package.

Additionally, big roll aluminum foil rolls has great light-blocking qualities. Certain dietary components, such vitamins and pigments, can degrade more quickly under the influence of light, which can cause discoloration and nutrient loss. Aluminum foil aids in maintaining the aesthetic value, nutritional content, and sensory aspects of packaged goods by obstructing light.

The quality and shelf life of food and beverages can also be adversely affected by moisture. Aluminum foil has moisture barrier qualities that keep water vapor out, preventing moisture-related issues like mold growth, wetness, and texture changes. Aluminum foil contributes to the maintenance of product quality and the extension of perishable goods' shelf lives by producing a moisture-resistant environment.

Aluminum foil is a trustworthy barrier against contaminants in addition to offering defense against oxygen, light, and moisture. It helps safeguard packed items against outside elements like dust, bacteria, and odors, ensuring the product is free from contamination and secure for consumption.

The variety of uses for aluminum foil in packaging applications demonstrate its adaptability. It is frequently used to wrap chocolate because it offers a lovely protective coating that helps keep its form and minimizes flavor loss. To keep them fresh and shield them from moisture and odors, cigarettes are typically wrapped in aluminum foil. The packaging of processed foods including ready meals, packaged snacks, and dairy goods is frequently sealed with aluminum foil. The aluminum foil's tight seal prevents leaks, keeps the product clean, and increases the shelf life of these convenience foods.

Aluminum foil is also resistant to intense heat and cold, making it ideal for packing both hot and cold foods. It has several uses, including baking, grilling, frying, and warming leftovers. Food is heated evenly while preserving its moisture and flavor because to aluminum foil's high heat resistance.

The excellent electrical conductivity and heat-dissipating properties of aluminum foil are crucial to the electrical sector. It is frequently utilized in the production of transformers, capacitors, and electrical conductors. Aluminum foil serves as a shielding material to increase the effectiveness and security of electrical systems and is a crucial part of the building of power transmission lines.

Aluminum foil is a common material used as insulation in the building industry. Because of its reflecting qualities, it is perfect for insulating buildings from heat and cold. To save energy use, maintain cozy interior temperatures, and improve energy efficiency, aluminum foil insulation is put in walls, roofs, and HVAC systems.

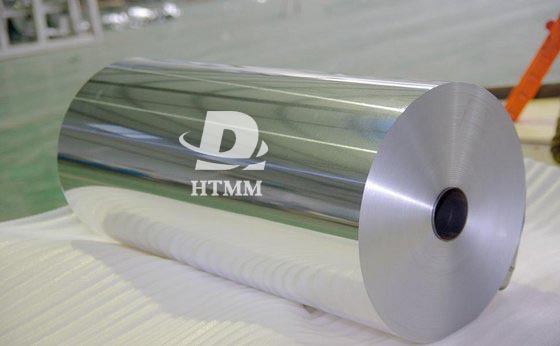

The manufacture of aluminum foil jumbo roll includes a number of intricate stages. Bauxite is refined to create pure alumina, which is then used to extract aluminum from the ore. The Hall-Héroult process, which involves the electrolysis of alumina in a bath of molten cryolite, is subsequently used to transform this oxide into metallic aluminum. The resulting aluminum metal is rolled into substantial coils and then thinned down using a variety of processes, including cold rolling and annealing. The foil must be manufactured using sophisticated equipment and with exact control of manufacturing parameters in order to achieve the necessary thickness, surface polish, and uniformity.

Additionally, aluminum foil production technology involves intricate mechanical and chemical processes. To guarantee uniform thickness and surface quality during rolling and annealing, accurate control of tension, temperature, and speed is necessary. For particular applications, additional treatments including lubrication, cleaning, and coating are utilized to improve the performance of the foil. In order to obtain the desired qualities and adhere to strict quality requirements, these processes require highly trained technicians and specialized equipment.

Aluminum foil develops into a significant and essential material given its wide variety of uses and intricate manufacturing process. It is a valuable component in many industries thanks to its contributions to construction, electrical systems, and packaging. The possibilities for using aluminum foil have been continuously expanded thanks to improvements in processing and manufacturing methods, which have also promoted global economic growth and raised people's standards of living.

In order to satisfy the various demands and expectations of its customers, HTMM is a respectable and customer-focused business that takes great delight in supplying high-quality aluminum foil. Through its persistent dedication to quality and its outstanding goods and services, HTMM has become recognized as a reliable supplier in the market.

The relentless attention of HTMM on upholding the highest quality standards in its aluminum foil products is one of the key elements influencing the company's success. The business is aware of how important aluminum foil is to several sectors, including building, electrical, and packaging. Because of this, HTMM uses exacting quality control procedures throughout the manufacturing process to guarantee that their aluminum foil constantly meets and surpasses industry standards.