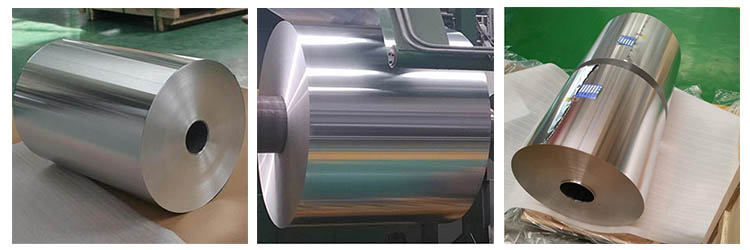

Aluminum foil 8011 has several characteristics and aluminum foil thickness that make it a suitable material for air ducting.

80 Micron aluminum foil Stability

8011 Aluminum Foil is a very durable material. Commercial grade aluminum foil used for air ducting is usually between 0.005 and 0.015 inches thick.The thickness is 80 micron aluminum foil. This aluminum foil thickness gives the aluminum foil enough stiffness to maintain its shape when formed into air ducts, but also flexibility when bent. Aluminum foil does not rust or corrode like steel. This durability means that aluminum foil air ducts can last for decades with minimal maintenance requirements.

80 Micron aluminium foil Easy Molding

80 Micron Aluminum Foil 8011 is easy to form into the complex rounded shapes required for air ducts. The paper can be heated to allow it to stretch over the shapes it forms and then cooled to retain its new shape. 80 micron aluminum foil ducts can generally be bent by hand to fit into tight spaces and around obstructions in the building. The flexibility of aluminum foil also makes it easier to install air ducts compared to rigid metal ducts.

80 Micron aluminium foil Light weight

Aluminum foil is significantly lighter than the steel or galvanized metal commonly used for air ducts. The light weight of Aluminum foil 80 micron l ducts simplifies transport, lifting and installation. Less labor and equipment is needed to position aluminum foil ducts during construction compared to heavier metal ducts.

Aluminium foil 8011 Resistance to moisture and air

Aluminium Foil 8011 has a smooth, non-porous surface that acts as an effective barrier against moisture and air. When forming aluminum foil channels, seams and joints are sealed with mastic, duct tape or liquid adhesive to seal any holes. This makes complete Aluminum foil 80 micron air ducts capable of keeping conditioned air flowing through the ducts instead of out. Moisture resistance is important as air ducts often pass through unconditioned areas such as attics and basements where humidity can reach high levels.

Aluminium Foil 8011 Noise reduction

The density of 8011 aluminium foil makes it an effective material for sound insulation. Aluminum foil ducts can reduce noise transmission from HVAC systems compared to other metal ducts. This noise reduction benefits both comfort and energy efficiency since HVAC systems don't have to run at higher speeds to compensate for noise escaping through metal ductwork.

Aluminum Foil 8011 Low price

Aluminum foil 8011 is usually much less expensive than the traditional galvanized metal or stainless steel foils used for air duct construction. The raw material cost for aluminum foil ducting is typically half that of metal ducting. Since aluminum foil is easier to form, labor costs during duct installation are also lower. Overall, 8011 aluminum foil ducts offer a lower cost alternative to HVAC ducts that perform comparably in terms of durability and airflow.In summary, 8011 aluminum foil exhibits several key characteristics that make it an ideal choice for constructing air ducts in residential and commercial buildings. 80 micron aluminum foil durability, ease of shaping, lightweight nature, air and moisture resistance, noise dampening and lower cost all benefit overall duct performance and ease of installation. While not as common as metal ductwork, 80 micron aluminium foil ductwork deserves consideration for new HVAC system designs and renovations aimed at minimizing material costs and environmental impact.

If you have any doubts about 80 Micron Aluminum Foil Please contact us.

Advantages of Aluminum Foil for Ventilation Ducts

Insulation - Aluminum Foil 80 micron lined ventilation ducts help insulate the ducts, reducing heat loss and heat gain. This improves energy efficiency by keeping the conditioned air at the desired temperature as it travels through the ventilation system. The foil cladding acts as a radiant barrier that reflects the sun's heat and prevents heat transfer between the duct and its surroundings. This is particularly important for supply ducts that pass through attics and unconditioned crawl spaces.

Condensation Control - Aluminum Foil 80 micron cladding also helps control condensation that can build up inside ventilation ducts. By insulating the duct and preventing heat transfer, the aluminum foil 8011 reduces the rate of moisture accumulation within the duct. This reduces the possibility of condensate leaking from the supply ducts or promoting mold growth within the return ducts. Less condensation means a ventilation system that works more efficiently.

Light blocking - Ducts lined with aluminium foil eliminate the penetration of light into the ventilation system. Light can promote the growth of algae and microbes inside ducts, degrading air quality. Blocking light with foil helps keep the ventilation system clean and free of contamination.

Here are some reasons why choosing HTMM aluminum foil can be a good option:

• Durability - HTMM aluminum foil is made with a specialized manufacturing process that allows it to be more durable and withstand daily use better than standard aluminum foil. The thin metal foils are subjected to intense twisting and tension, which helps align the metal particles, creating a stronger, more tear-resistant foil metal. This makes them less likely to tear or puncture when used for cooking or wrapping foods.

• Heat resistance - The manufacturing process also helps the HTMM aluminum foil withstand higher temperatures compared to standard nest. This means that HTMM foil can better resist burn holes when used for baking or when exposed to hot pans. The extra heat resistance also means it can be better shaped into pans without fail.

• Non-stick - In addition to being more durable, HTMM foil has a non-stick coating applied during the manufacturing process. This makes food less likely to stick to the foil when wrapping or cooking and easier to clean after use. The non-stick coating also adds heat resistance.

• Low waste - Since HTMM aluminum foil is torn and punctured less often, it tends to create less aluminum foil waste overall. You'll likely get more uses out of a single roll of HTMM foil metal than a standard slot, reducing the amount of foil metal you need to buy over time. This reduces aluminum waste entering the landfill.

• Odor and chemical resistance - HTMM aluminum foil's thicker composition and non-stick coating make it more resistant to absorbing odors and chemicals from foods during cooking and storage. This means that foods will transfer less odor to wrapped items and vice versa. foil will retain their properties for longer.

• Smooth texture - HTMM Aluminum foil production gives it a smoother, more uniform texture that allows it to form well into pan shapes with fewer air pockets. This promotes better heat circulation and more even cooking or baking. The softness also reduces the chances of food sticking and tearing of the foil.

In summary, HTMM aluminum foil offers various advantages over standard aluminum foil, including greater durability, heat resistance, non-stick properties and reduced waste, making it a good option for those looking for higher performance. high from their foil. The specialized manufacturing process distinguishes alu foil by aligning the metal particles to create a stronger, longer-lasting product.