The Important Position of 11Micron Aluminum Foil Large Roll

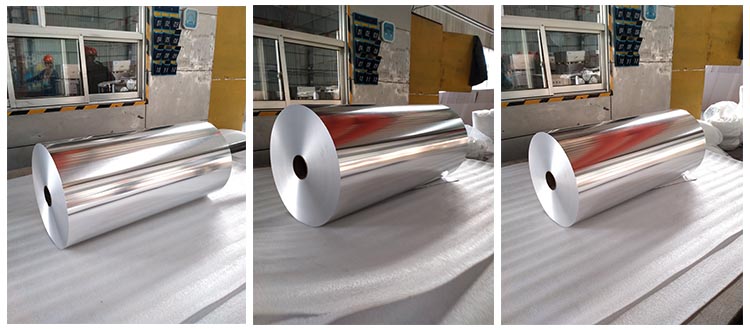

In modern industrial production, Aluminum Foil Large Roll, as a multifunctional material, has become an indispensable basic material in many fields such as packaging, electronics, and construction due to its excellent physical and chemical properties. Among them, 11-micron thick aluminum foil large roll occupies an important position in the market due to its perfect balance between performance and cost. This ultra-thin aluminum foil not only maintains sufficient mechanical strength, but also optimizes the amount of material used, providing end users with extremely high cost performance.

As China's leading aluminum foil manufacturer, Henan HTMM Alu foil has focused on the research and development and production of 11 micron aluminum foil for many years and has established a complete quality control system and technological innovation mechanism. The company has introduced internationally advanced production equipment and combined with independent process innovation to make the products reach the industry-leading level in terms of thickness uniformity, surface quality and mechanical properties. The products are exported to international markets such as Europe, America, and Southeast Asia, and have been recognized by many well-known companies.

Diversified Application Areas of Micron Aluminum Foil : Food and Pharmaceutical Packaging Industry

In the field of food packaging, micron aluminum foil roll jumbo has become the preferred material for high-end food packaging due to its excellent barrier properties.

Specific applications include:

►Chocolate packaging: As an inner barrier material, it can effectively block the intrusion of oxygen, water vapor and light, and maintain the freshness and taste of chocolate. The food-grade aluminum foil produced by HTMM has passed FDA certification, and the heavy metal content is far below the standard limit, which is safe and reliable.

►Dairy product packaging: used for yogurt cup sealing film, milk powder inner bag, etc., with good heat sealing performance and puncture resistance. The special aluminum foil developed by the company can still maintain stable sealing performance at a heat sealing temperature of 180℃.

►Convenient food packaging: As a barrier layer for cooking bags, it can withstand high-temperature sterilization at 121℃. HTMM's aluminum foil has been specially treated and still maintains excellent interlayer bonding after being compounded with various plastic films.

►In terms of pharmaceutical packaging, micron aluminum foil roll jumbo is mainly used for:

Blister packaging: As the base material of pharmaceutical aluminum-plastic blisters, it has good formability and barrier properties. HTMM's pharmaceutical foil products meet USP standards and have extremely low volatile content.

Pharmaceutical aluminum bags: used for moisture-proof packaging of powders and granules. The medicine foil products developed by the company have stable moisture-proof performance and can still maintain good barrier effect in RH90% environment.

Quality advantages of HTMM's 11Micron Aluminum Foil

• Advanced production equipment and technology

HTMM has invested in the construction of a world-class production line, and all key equipment has been introduced from Germany, Japan and other countries, including:

Sendero six-roller cold rolling mill: equipped with ABB automatic thickness control system, rolling accuracy reaches ±0.001mm

Andrews annealing furnace: adopts a fully automatic atmosphere protection system, temperature uniformity ±2℃

Kangfu slitting machine: equipped with a high-precision laser edge alignment device, slitting accuracy ±0.1mm

The company's original "three-step method" rolling process, through precise control of the pass reduction rate and the intermediate annealing process, makes the product grain size reach above level 8, which is much higher than the industry average. In terms of surface quality control, the "micro-lubrication" rolling technology is used to control the surface roughness Ra of the aluminum foil below 0.2μm.

• Strict quality control

HTMM has built a complete quality control system including:

Control of raw materials: A spectral analysis testing every aluminum ingot demonstrates control of the chemical composition

Process control: There are 21 control points for quality control in the process that allows full-process monitoring

Inspection of the final product: The finished product is sampled in accordance with AQL 1.0 standards

Traceability system: Each aluminum foil roll has a number allocated to it, as well as data from the entire production process

The company laboratory contains capabilities related all modern testing equipment, examples of which include: scanning electron microscope, energy spectrometer, inductively coupled plasma mass spectrometer, etc., permitting use of the entire spectrum of material tests. The mechanical properties test (tensile testing) can usually be performed using the Instron universal testing machine, producing very accurate and reliable data.

• Excellent product performance indicators

The 11 micron aluminum foil produced by HTMM likewise exceeds generally published performance indicators in many areas:

Thickness uniformity: measured standard deviation ≤0.0005mm

Tensile strength: 85 - 115 Mpa in the longitudinal direction and 75 - 105 Mpa in the transverse direction

Elongation: ≥2% in the longitudinal direction and ≥1.5% in the transverse direction

Pinholes: ≤30/m² (tested under a standard light source, e.g., sun)

Surface wetting tension: ≥38 mN/m (after application of corona treatment)

This impressive performance criteria gives HTMM's products a considerable competitive edge in the high-end application fields. For example, in the capacitor industry, capacitors constructed of HTMM aluminum foil have a loss tangent value that is 15-20% lower than the industry average, combined with a service life extension by over 30%.

Environmental Protection and Sustainable Development

HTMM values environmental protection and sustainable development:

Energy utilization: utilize waste heat recovery system and increase energy utilization by 25%

Waste water treatment: achieve 95% recycling rate of production water

Waste recovery: 100% recovery rate of aluminum chips, 30% of recycled aluminum is added in melting and casting

Product environmental protection: passed RoHS, REACH and other certifications, heavy metal contents are significantly below limits

The company actively develops more environmentally friendly processes in our manufacturing, such as taking on chromium-free surface treatment technology, low-energy rolling process, etc. to promote a green development for the industry. In 2022, HTMM received a designation of "National Green Factory".

With an ongoing enhancement of the material performance requirements of each respective industry, the demand for 11-micron aluminum foil will continue to expand. Especially in high-end fields of new energy, electronical changes, etc. Where more stringent requirements have been imposed on the uniformity, surface quality as well as the mentioned functional features of the foil. HTMM will continue to increase the investment in scientific research and development, keeping in mind the applicability, with an emphasis on ultra-thin, high strength and multi-functional composite aluminum foil products to fulfil the ver

In the future, HTMM plans to invest in building a digital smart factory and achieve intelligent control over the entire production process based on the Internet of Things, big data and other technologies, so as to further improve the stability of the quality of its products. At same time, HTMM plans to strengthen cooperation with universities and research institutes to achieve breakthroughs in the new aluminum alloy materials, new surface treatments, and consolidate its technology leadership position in the industry.

As a benchmark enterprise of China’s aluminum foil industry, HTMM will adhere to the business philosophy of “quality first, customer first,” and provide global customers with and better quality 11-micron aluminum foil products and services, as well as to promote technological progress and high-quality development of the aluminum foil industry.