Alloys and states of Aluminum Flexible Packaging Foil for flexible packaging

Alloy types

The alloy selection of aluminum foil for food flexible packaging needs to consider corrosion resistance, processing performance and food safety standards. The main alloy types used are 1235, 1145, 1100 and other industrial pure aluminum series.

1235 alloy aluminum foil demonstrates excellent comprehensive performance in food packaging. It has higher strength than pure aluminum and maintains good shape stability during the packaging molding process. It is particularly suitable for making packaging bags that need to withstand a certain level of mechanical stress, for example, self-supporting bags or zipper bags. Meanwhile, the 1235 alloy has a strong resistance to corrosion, meaning it can withstand the attack of any acidic or basic components in foods and retain food quality.

The 1145 alloy aluminum foil is well-known for its good ductility. In the processing operation of food soft packaging, this alloy can withstand a lot of complexity in forming processes like deep drawing or embossing so that packaging containers can be made in multiple shapes. In addition, the 1145 alloy has significant barrier properties to water vapour and oxygen, and is typically used in food packaging applications with high requirements for moisture and oxidation resistance like nuts, tea, etc.

The 1100 alloy aluminum foil has a purity of more than 99.00% and extremely high surface finish. Although it has lower mechanical property, the 1100 has an outstanding surface for printing adaptations. The surface has good adhesion for printing inks and coatings, which can produce vivid color prints to compete and increase the visual appeal of food packaging items. It typically is found in the high-end food or gift packaging arena.

Material State

Food soft packaging aluminum foil typically exists in a "dead soft" condition. Depending on the specific alloy, dead soft condition is created by a special annealing process. The aluminum foil is refined and residual stress is eliminated after adequate annealing, so it has good ductility and flexibility.

Ultra-soft aluminum foil has many advantages in flexible packaging. Its softness makes it suitable for compounding with plastic films, paper, and other materials to create a multi-layer composite packaging structure to satisfy the different packaging applications for a variety of foods. At the same time, the ultra-soft state makes sure that the aluminum foil can bond to the sealing layer during the heat sealing process, giving it a strong bonding effect to avoid any food leakage or contamination from outside bodily sources. Additionally, the aluminum foil in this state has good wrinkle resistance and is able to keep the loose outer surface flat in even the more complicated packaging molding processes to ensure the printed pattern maintains its clarity and beauty.

Specific Application of Aluminum Foil for Flexible Packaging

Moisture-proof and fresh-keeping

Moisture can cause food to deteriorate or become moldy while being stored, and aluminum foil has almost perfect barrier properties to water vapor. In the case of puffed foods like potato chips and biscuits, aluminum foil composite film can preserve the crunchiness of food for a long time so that they do not soften from moisture absorption. For food from fats such as fresh meat and seafood, aluminum foil packaging can effectively prevent any water loss, and can retain the freshness and juicy flavour of food, thereby prolonging the shelf life.

Anti-oxidation and aroma keeping

Oxygen is a predominant factor that promotes food oxidation and spoilage, which can lead to oil rancidity, and vitamin destruction of nutrients, and can even create toxic substances. Aluminum foil has strong oxygen barriers, and can completely isolate a food from outside air. In nut and baked goods packaging, aluminum foil can prevent food from oxidising from internal fat sources that produce rancid smell, and can help keep food's aroma and nutrition value. This could be incredibly important for aroma sensitive foods, such as coffee and tea, since aluminum foil packaging can keep aroma components intact, to avoid volatile losses.

Light-shielding protection

Ultraviolet and visible light in light will accelerate the decomposition of pigments, vitamins and other ingredients in food, causing food to fade and deteriorate. Aluminum foil has zero light transmittance and can completely shield light, providing reliable light protection for food. In chocolate and candy packaging, aluminum foil can prevent melting caused by temperature changes, and prevent discoloration and taste deterioration caused by light exposure, maintaining the appearance and quality of food.

Heat sealing and processing adaptability

After aluminum foil is compounded with heat-sealing materials such as polyethylene (PE) and polypropylene (PP), it can be made into various forms of packaging bags through heat sealing process. Its good heat sealing performance ensures the sealing and reliability of the packaging, and is suitable for various packaging forms such as vacuum packaging and inflatable packaging. In addition, aluminum foil has strong processing adaptability and can be made into three-side sealed bags, self-supporting bags, coils and other forms according to the packaging needs of different foods, meeting the high-speed operation requirements of automated packaging production lines.

High-temperature cooking and aseptic packaging

In the field of high-temperature cooking food packaging, aluminum foil composite film has become an ideal packaging material due to its excellent high-temperature resistance and barrier properties. It can withstand high-temperature cooking treatment above 121°C, while preventing the invasion of external microorganisms, ensuring the commercial sterility of food, and is widely used in the packaging of convenience foods, canned meats and other products. For special fields such as aerospace food and military food that need to be preserved for a long time, aluminum foil aseptic packaging is an indispensable choice.

The quality of aluminum foil for flexible packaging produced by Henan HTMM Company in China is good.

Advanced production technology and equipment

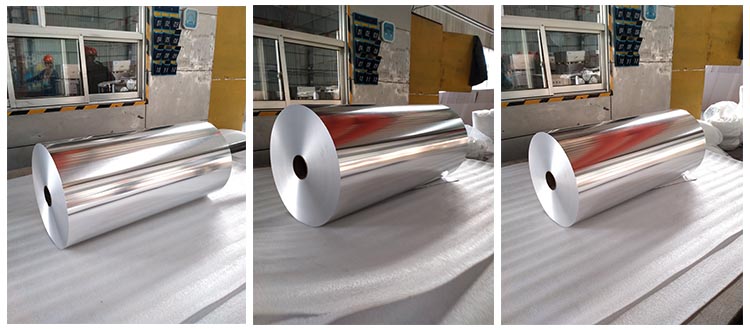

Henan HTMM Company has a world-class aluminum foil production base, and has introduced advanced equipment such as high-precision four-roll reversible aluminum foil rolling mill, automated slitting equipment and intelligent annealing furnace. The high-precision rolling mill can accurately control the thickness of the aluminum foil within a tolerance range of ±2%, ensuring thickness uniformity and meeting the strict requirements of food packaging for material consistency. The company adopts the advanced production process of "continuous casting and rolling + cold rolling annealing". From aluminum ingot smelting to finished product storage, each link has realized digital monitoring to ensure that the mechanical properties and surface quality of the aluminum foil are stable and reliable.

Strict quality control system

HTMM Company has established a quality control system throughout the entire industry chain, and has implemented multiple strict inspections from raw material procurement to finished product delivery. Advanced equipment such as X-ray thickness gauges, plate shape detectors, and universal material testing machines are used to conduct 100% online inspection of key indicators such as thickness, mechanical properties, barrier properties, and surface quality of aluminum foil. The company has passed ISO 9001 quality management system, ISO 22000 food safety management system and other international certifications to ensure that the products meet domestic and international food contact material safety standards, such as China GB 10368, EU EC 1935/2004, etc.

Excellent product performance

The food soft packaging aluminum foil produced by HTMM has excellent barrier properties. The oxygen permeability of 7μm thick aluminum foil is less than 0.1cm³/(m²・24h・0.1MPa), and the water vapor permeability is less than 0.1g/(m²・24h), which is much better than ordinary plastic packaging materials and can effectively extend the shelf life of food. It has excellent mechanical properties, and the elongation at break can reach more than 15%. It is not easy to break during the packaging process and meets the requirements of high-speed packaging production lines. The aluminum foil has a high surface finish, a haze value of less than 1%, and excellent printability, which can achieve high-definition color printing and enhance the visual appeal of food packaging.