Used in the construction of bathroom and sauna, aluminum foil has good plasticity; corrosion resistance; heat insulation and waterproof performance; high reflectivity; low specific gravity and beautiful appearance. Due to its thermal insulation properties, aluminum foil is widely used to build individual bathrooms and saunas, as well as to make warm floors. In order to reduce the heat exchange between bathing or sauna and the environment, the inner wall and ceiling are lined with aluminum foil, and then covered with plates or partitions. The heat generated by the radiator will not fully heat the room. Up to 30% of the heat is lost through the outer wall. The situation is similar for warm floors. Utilizing the characteristics of aluminum foil-high heat reflectivity-by making a foil screen between the battery and the wall or between the heating element and the floor, you will reduce heat loss and reduce heating energy consumption. The aluminum foil is completely non-toxic and vapor-proof. With high (up to 97%) reflectivity, it is not afraid of high and low temperatures, humidity and humidity.

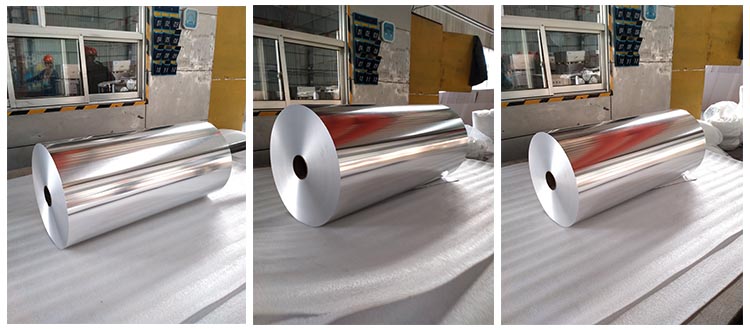

Aluminium Foils in Coils 8011 Alloy for Food Industry Use:

Impermeability. The thickness of the aluminum foil is 0.025 mm or more, and it is almost impermeable to steam and gas. Even with a thickness of 0.009mm, the water vapor permeability is only 0.01g/m2/day, which can be said to be acceptable.

Synthetic materials are based on chain-like macromolecules held together by cohesion. However, in this case, a very significant hollow space remains in the material structure. Due to the difference in water vapor pressure, partial pressures are generated on both sides of the synthetic film. As a result, water vapor permeates through the macromolecular network from the wetter side of the film to the drier side and evaporates again.

On the other hand, the foil has a more ordered network of metal atoms, arranged so tightly that no gas other than hydrogen can penetrate it.

Corrosion resistance. Compatible with a variety of chemicals. The natural surface oxide of the aluminum foil covered in the air acts as a barrier to prevent corrosion and contact with chemically active substances to a large extent.

health. Compatible with all foods. Aluminum foil is non-toxic. It does not bring any peculiar smell or odor to food, does not allow water and other liquids to pass through, and does not absorb lubricants. During the production process, the aluminum foil becomes sterile and cannot become a favorable environment for bacteria to survive. It is a material that is inert to almost any food, beverage and cosmetics. This explains why aluminum foil is widely used for packaging medical products, and its storage conditions are particularly strict.

The ability to obtain and maintain a given shape. The foil can be bent and folded as needed. This may be the only material that can be easily configured to the desired configuration. It is almost impossible to wrap something other than foil, such as a chocolate Santa or a rabbit, to completely repeat the shape of the product. In addition, it is particularly important that not only the manufacturer, but also the consumers themselves can use foil to "shape" the packaging-whether it is a child leaving a chocolate "later" or the hostess wants her cooking "masterpiece" , In order to maintain its original freshness.

Aluminium Foils in Coils 8011 Alloy for Food Industry Use.Absolutely opaque. This quality of aluminum foil is worth talking about in more detail. The fact is that the recently published research results of the Fraunhofer Institute for Food and Packaging Technology (Germany) convincingly prove that the taste and other qualities of dairy products can quickly deteriorate under the influence of the strong light normally used. In the store refrigerator. Expert opinion is that aluminum caps provide better protection for cream exposed to light than plastic caps. The results of these studies confirmed earlier conclusions made by scientists at the same institute based on experiments that studied the effects of light on yogurt.