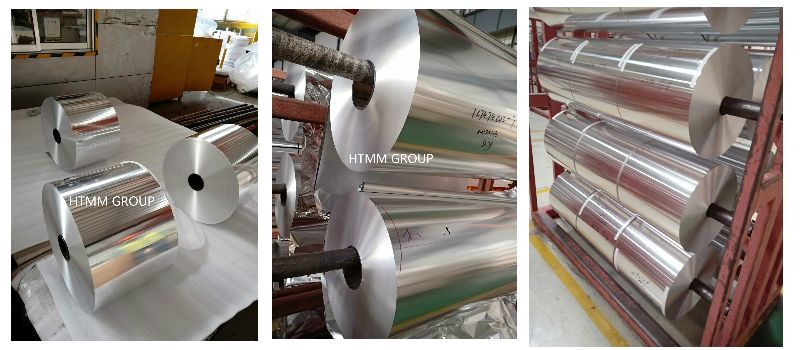

We (HTMM) Aluminum were established in 2009. Through more than 10 years of development in China and abroad, we have now developed into a leading diversified aluminum product manufacturer in China. Our factory is located in Binzhou City, Shandong Province and has very rich experience in aluminum rolling and processing. We have exported our products to more than 70 countries, served more than 3,500 customers, and once received praise from customers for the quality of our products. Our best-selling products include household aluminum foil, aluminum foil for lamination, as well as industrial foil, heat sealing foil and food container foil.

Our facility produces over 80 million tons of goods annually and is equipped with the most sophisticated manufacturing lines and cutting-edge technologies. To guarantee the consistency of the quality of our products, we rigorously abide by international quality standards like ISO 9001. Our factory will process aluminum ingots through rolling, cooling, annealing, cooling, and other steps after receiving the customer's order.Composite foil includes the foil used for chocolate packaging that we will talk about in this post. We offer our premium 8079/8011/1235 alloy aluminum foil in various widths and thicknesses to meet the demands of our customers. We can also ensure that our customers receive their orders on schedule thanks to our robust transportation network.

In order to guarantee the dependability of our product quality, we strictly adhere to international quality standards like ISO 9001 while producing chocolate foil in our facility, which is equipped with the most sophisticated production lines and cutting-edge technology. Our factory will process aluminum ingots through rolling, cooling, annealing, cooling, and other steps after receiving the customer's order. Our rolling mill uses an ABB plate control system and a HONEYWELL thickness control system during the rolling process to guarantee that customers can receive aluminum foil in a variety of thicknesses during the whole rolling process. Additionally, we will use sampling techniques to assess the quality of each batch of goods received from our clients.

Third-party quality inspection certifications from SVHC, the US, Europe, and other countries are held by our (HTMM) facility. These certifications attest to the fact that our foil is completely compliant with good food-grade foil and may be used in good contact with chocolate. It can guarantee food safety and shield aluminum foil from damaging your health.

A unique kind of aluminum foil called "chocolate foil" is used just to package chocolate bars. "Chocolate wrapper" or "chocolate foil" are common names for it. There are numerous benefits to using this kind of foil when packaging chocolate. First and foremost, the chocolate foil serves as a barrier to shield the chocolate from outside elements including moisture, air, and light. The taste, texture, and general quality of the chocolate are all preserved thanks to this protection. Second, chocolate foil packages newly formed or tempered chocolate bars in a simple and safe manner due to its exceptional heat resistance.

It makes sure that when warm or molten chocolate comes into contact with the aluminum foil, it won't melt or distort. The chocolate foil is made with ease of unwrapping in mind, making consumption enjoyable and hassle-free. The aluminum foil's suitable thickness and smooth surface facilitate easy opening of the chocolate bar without compromising its shape.

Additionally, in order to improve the visual attractiveness of the chocolate bars, our manufacturer (HTMM) may personalize the chocolate foils for customers with different colors, designs, and branding aspects. Chocolate bars are frequently packaged using aluminum foil in addition to chocolate foil. Chocolate producers may find aluminum foil to be a viable option as it shares many of the same benefits and features as chocolate foil.

The ductility and elasticity of aluminum foil itself are some benefits of utilizing it to package chocolate. Chocolate bars of all shapes and sizes can be easily wrapped with aluminum foil because of its extreme ductility and flexibility. The foil provides cozy and safe wrapping by conforming to the shape of the chocolate bar. Aluminum foil is an eco-friendly option for packaging chocolate because it is recyclable.

Recycling aluminum foil contributes to waste reduction and energy conservation, enabling the development of more environmentally friendly packaging options. Utilizing aluminum foil paper instead of plastic packaging can help save the environment, which is essential to human survival.

Both small and major chocolatiers employ aluminum foil packaging, which is a traditional way of packaging chocolate bars. The chocolate maker molds or tempers the chocolate bar to the appropriate shape, texture, and consistency before starting the foil wrapping procedure. After cooling, the bars are ready to be packaged. Cut the aluminum foil to the appropriate size based on the chocolate bar's dimensions. To

guarantee full coverage, the foil should be somewhat larger than the chocolate bar.

Position the chocolate bar in the middle of the foil. Next, encircle the stick in foil, making sure to fully enclose all sides. A tight and safe package is created by folding and sealing extra foil. Additional processes, such the addition of attractive labels, stickers, or exterior packaging for branding and marketing, may be applied to the finished packed chocolate bar.

Because it is aesthetically pleasing, heat resistant, and provides protection, aluminum foil is an essential component of chocolate bar packaging. Because of their superior qualities, aluminum foil and chocolate foil are both frequently utilized in the chocolate industry. While aluminum foil offers functionality and variety, chocolate foil caters specifically to the demands of the chocolate producer.

The chocolate bars are packed securely using aluminum foil, preserving their freshness, flavor, and general quality. Aluminum foil's stretchability and suppleness allow chocolate makers to design aesthetically pleasing packaging that improves the shopping experience for customers.