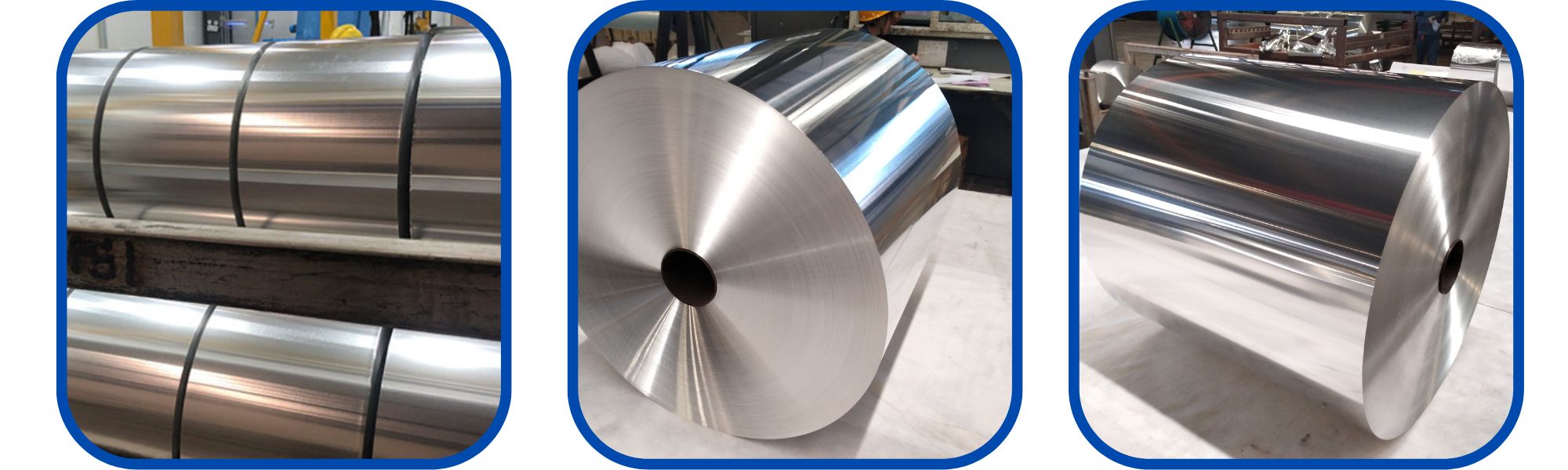

An industry standard 8011 aluminum foil jumbo roll grade commonly utilized in consumer flexible packaging is 8011 aluminum foil jumbo roll. Manufactured in jumbo roll formats, 8011 Household Aluminum Foil Raw Material provides converters and brand owners an economical raw material solution. This article will examine the key characteristics and applications of 8011 Household Aluminum Foil Raw Material.

Properties of Aluminium Foil Raw Material

Let's first explore some inherent properties that make Aluminium Foil Raw Material well-suited for household end uses. In terms of thickness, The thickness of general household aluminum foil is between 8 microns and 40 microns. Being thinner than commercial-grade foils, 8011 Household aluminum foil raw materials maintains good flexibility even at higher speeds on packaging lines.

Aluminum's strong crystalline structure provides Household aluminum foil raw materials with superb barrier attributes. It acts as an effective seal against oxygen, moisture, aroma compounds and light which are critical for packaging various household items. The foil is non-toxic and FDA compliant for direct food contact applications.

Aluminum foil raw material jumbo roll also has good heat resistance up to approximately 120°C/250°F, allowing brief oven or microwave heating applications. It can be easily printed, coated and converted using standard industry methods. Importantly, aluminum foil raw material jumbo roll is 100% recyclable and highly sustainable with infinite recyclability potential.

Specifications of 8011 Aluminum Foil Jumbo Rolls

Flexibility in high-speed consumer packaging requires consistent performance from raw material suppliers. Key specs for 8011 foil rolls include:

Alloy/temper: 8011 / O

Thickness - 8 microns-40 micron ; ±10 micron tolerance

Width - Standard 200-800mm; ±3mm tolerance

Length - Jumbo Roll Aluminum Foil

Core - 76mm heavy-duty cardboard for wind stability

Surface - Mill finish or optional treatments

Purity - Minimum 99% aluminum composition

Consistency - Gauge control ±1%, width ±0.5%

Certifications - ISO, FDA food compliance

Suppliers strictly control production variables to assure these specifications batch-over-batch for optimized packaging operations.

Manufacturing of 8011 Household Foil

The process flow to manufacture 8011 aluminum foil rolls begins with high purity aluminum ingots. Through controlled hot and cold rolling schedules, ingots are progressively reduced into thin foil sheets with precise gauges.

Key manufacturing stages include:

Melting and alloying aluminum to required composition

Hot mill rolling into thinner slabs at 500-600°C

Pickling to clean surfaces followed by cold rolling

Bench annealing to soften metal and refine grains

Additional cold rolling reduces thickness to 8011 gauge

Stress relieving heat treatment and 2-3% stretcher work

Slitting master coils, quality inspection, winding rolls

Advanced quality control systems objectively verify mechanical properties and gauge tolerances meet commercial requirements at each process checkpoint. State-of-the-art facilities maintain tight manufacturing discipline for consistent 8011 foil supply.

Packaging of Aluminum Foil Rolls

Proper packaging readies 8011 foil for downstream flexible packaging applications. Key aspects involve:

Wrapping each roll tightly in stretch film or shrink wrap

Placing desiccants inside master cartons to absorb moisture

Robust quad-wall cardboard cartons for handling/storage

Shrink wrapping pallets securely with identification labels

Temperature controlled storage under 25°C and 50% RH

Optimal 2 year frozen or 1 year ambient shelf life

Ensuring FIFO (first in, first out) stock rotation practices

Such packaging and warehousing procedures protect the integrity and performance properties of 8011 foil rolls through the supply chain.

Common Converting Methods

Let's take a look at how 8011 foil rolls are converted on high-speed lines to manufacture household flexible packaging solutions:

Pouch and Bag Production

Form-fill-seal machinery formats bags and pouches

Lidding Sheets

Rollfed or cut-sheet stamping, printing, coating, sealing

Roll Printing & Slitting

Directly applies high-quality graphics

Component Punching

Automated turret dies cut individual foil parts

Component Assembly

Piecing, creasing, folding items on packaging lines

Thermoforming

Heated vacuum forming of trays, pads, coverings

Aluminum foil is continuously drawn from parent rolls and transformed using techniques like adhesive lamination, printing, perforating and heat sealing. Robotic handling marries multiple consumer-friendly features onto single-serve and bulk household packaging formats.

Applications of 8011 Household Foil

Let's explore how 8011 aluminum foil's properties are put to use:

Food packaging and storage - Wraps, baking pans, roasting bags

Non-food household items - Wrapping gifts, toys, small appliances

Moisture resistant liners - For freezers, pantries, storage boxes

Oven/microwave safe covers - For platters, dishes, container lids

Food serving overwraps - Foils over casserole dishes, platters

Sandwich/snack wrappers - Individual serve formats for on-the-go

Greaseproof bakery papers - For commissary or in-store bakery use

Holiday decorative foils - For embellishing seasonal items

The diversity of 8011 aluminum foil applications streamlines household management tasks through convenient single and bulk use formats.

Quality Assurance of Aluminium Foil Raw Material

Maintaining safety and performance requires strict quality measures:

ISO 9001 certification of quality systems

ISO 22000 food safety management standard

FDA food contact material compliance

Periodic formulations testing

Raw material and packaging specifications

Statistical process control monitoring

Robust traceability programs

Customer quality auditing

Comprehensive quality assurance programs assure the 8011 household foil and finished packaging will safely contain and protect contents as intended. Customers can feel confident unspecified contaminants or inconsistencies will not compromise products.

8011 gauge aluminum foil manufactured precisely to specifications and packaged securely delivers consumer product manufacturers a versatile raw material substrate. Conversion into a wide variety of economically produced household packaging formats streamlines daily tasks. Supported by comprehensive quality assurance, 8011 foil hygienically contains contents as intended. With aluminum's 100% recyclability, it stays environmentally preferable for myriad flexible packaging applications now and long into the future.