Understanding 8 Micron Aluminum Foil

Micron means one millionth of a meter and is a unit used to measure the thickness of ultra-thin materials. The 8 micron aluminum foil we mentioned refers to aluminum foil with a thickness of only 0.008 mm. Although this thickness is extremely thin, its performance is extremely excellent and it is widely used in packaging materials.

The characteristics of this ultra-thin aluminum foil determine that it can provide excellent barrier protection while remaining lightweight, flexible and cost-effective, which is quite economical. This material is widely used in a variety of different fields such as food, beverage, pharmaceutical, personal care and industrial packaging. In addition, it is easy to laminate with other materials such as plastic film or paper, so its functions and application range are wider, which also enhances its versatility and performance in packaging systems.

Key Features and Benefits of 8 Micron Aluminum Foil

Due to the unique properties of aluminum foil, 8 micron aluminum foil has become an indispensable component of modern packaging solutions:

1. Excellent barrier properties

Aluminum foil has the characteristics of gas and moisture barrier. Even with a thickness of only 8 microns, it can effectively block external factors such as gas, light, oxygen, etc. This is essential for maintaining product freshness, especially for perishable products. Aluminum foil can greatly extend the shelf life of such products.

2. Lightweight and high strength

One of the most notable features of 8 micron aluminum foil is that it has sufficient tensile strength for easy handling, forming and sealing, which can minimize material usage and weight. Based on this feature, aluminum foil materials can reduce transportation costs and reduce environmental impact.

3. Flexibility and conformability

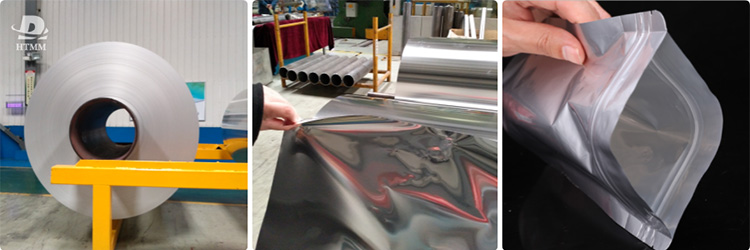

The ultra-thin nature of aluminum foil provides a high degree of flexibility and can adapt to products of various shapes and sizes. This is particularly important for aluminum foil used in flexible packaging, because aluminum foil must adapt to a variety of packaging formats, such as pouches, rolls, and sheets.

4. Heat resistance and sealing properties

The excellent heat resistance of aluminum foil makes it an ideal choice for packaging applications using heat sealing processes. When used for lamination, it can be laminated with other materials to create a composite multi-layer material with excellent sealing properties.

8 Micron Aluminum Foil Flexible Packaging Applications

Flexible packaging aluminum foil applications are one of the largest markets for 8-micron aluminum foil. It can extend shelf life, improve product safety, and enhance the aesthetics of product packaging, and is favored by packaging designers and manufacturers.

• Food packaging

From snacks and candies to dairy products and ready-to-eat foods, as well as other food packaging that requires sealing and extends shelf life, 8-micron aluminum foil helps maintain the flavor, aroma and nutritional value of the product. It is usually laminated with plastic films such as PET or BOPP to form a multi-layer composite material that is both practical and aesthetic. It has multi-layer durable properties.

• Pharmaceutical packaging

In the pharmaceutical industry, maintaining product integrity and ensuring safety are crucial. 8-micron aluminum foil is commonly used in blister packaging and strip packaging. The characteristics of aluminum foil can help packaging protect sensitive drugs from moisture and light. Its smooth appearance also allows for compact packaging, which is ideal for storage and transportation in areas with limited space.

• Cosmetics and personal care

Cosmetics often contain ingredients that are sensitive to environmental factors. Using aluminum foil for flexible packaging ensures that products remain stable for a long time, extending the shelf life of cosmetics, while aluminum foil can make the outer layer of flexible packaging more colorful, providing manufacturers with a high-end appearance that enhances consumer appeal.

• Role in lamination

Laminating aluminum foil requires bonding aluminum foil to other materials such as paper, plastic or other metal films to form a new composite material. This multi-layer structure combines the best characteristics of each material to form a strong, heat-resistant and unique-looking package to suit different packaging needs.

Laminated structure types and their applications

PET/aluminum foil/PE: commonly used in food bags and packaging bags.

Paper/aluminum foil/PE: suitable for pharmaceutical and tobacco packaging.

BOPP/aluminum foil/LDPE: provides high barrier and sealing properties for snacks and dry goods.

In these laminates, the 8-micron thick aluminum foil acts as the main barrier layer to protect the product from external factors such as sunlight and oxygen, while the outer layer provides printability and mechanical durability to the product. This combination is the cornerstone of laminated aluminum foil, allowing manufacturers to produce products that meet modern packaging needs.

8 Micron Aluminum Foil Production and Quality Control

Exquisite craftsmanship and strict quality assurance are essential factors in producing high-quality 8 micron aluminum foil. The process usually involves hot rolling aluminum sheets into thin sheets, and then cold rolling to reach the final thickness. After cold rolling, the aluminum foil is annealed, a process aimed at improving the ductility of the aluminum foil and removing residual oils in the aluminum foil material.

Key quality parameters include:

Thickness uniformity

Number of pinholes

Tensile strength

Surface finish

Factories usually require advanced measurement systems and automated inspection tools, which can ensure that each roll of aluminum foil meets international standards and is of suitable quality for critical applications.

8 Micron Aluminum Foil Environmental Considerations

Sustainability is a growing concern in the packaging industry, and aluminum foil has many advantages in this regard. Aluminum foil is 100% recyclable without loss of quality. And its thin profile means less material is used per package and its material is more durable. When laminated with biodegradable or recyclable packaging materials, 8 micron aluminum foil can greatly help create environmentally friendly packaging solutions.

In addition, the industry is also working on developing single-material packaging formats that include aluminum foil materials, with the goal of simplifying the recycling process and reducing environmental impact.

8 Micron aluminum foil is a high-performance and cost-effective material. It is widely used in both flexible packaging aluminum foil and laminated aluminum foil packaging, demonstrating its versatility and key role in modern packaging solutions.

Whether it is food preservation or pharmaceutical protection, this ultra-thin aluminum foil has excellent barrier properties, mechanical strength and adaptability.

In the modern society, the demand for lightweight, sustainable and high-barrier food packaging is growing, and 8 micron aluminum foil will continue to be a key material for innovative packaging design. Both manufacturers and brand owners can get the effects they want and benefit from its proven performance, recyclability, and compatibility with advanced lamination and printing technologies.

By investing in high-quality aluminum foil materials and working with reliable suppliers, companies can ensure that their products are well protected and have a beautiful appearance while meeting environmental standards to adapt to market needs, which can help them stay competitive in a rapidly developing market.