What is 65 microns aluminum foil 3004 Aluminium Foil? Why is it suitable for lunch boxes?

Aluminum foil is an ultra-thin aluminum sheet, and 65 micron aluminum foil (0.065 mm) is considered an average thickness - not too thick (otherwise the cost is high), nor too thin (otherwise it is easy to break). This thickness simply takes into account both strength and cost, and the prepared lunch boxes are not easy to deform and can withstand high temperatures.

Its advantages are particularly suitable for food packaging:

Completely isolated from air and moisture, food is not easy to deteriorate, and freshness lasts longer.

It is resistant to high temperatures, can be put into microwaves and ovens (unlike plastic, which deforms when heated and even releases harmful substances).

It is easy to shape, can be pressed into lunch boxes of various shapes, suitable for various foods.

Safe and non-toxic, meets food standards, and will not release harmful substances like some poor-quality plastics.

Therefore, many foods that require high freshness, such as air-conditioned foods, high-end foods, and pre-prepared foods, use 65 micron aluminum foil lunch boxes.

How are aluminum foil lunch boxes made?

The production process of aluminum foil lunch boxes is actually quite interesting, mainly divided into several steps:

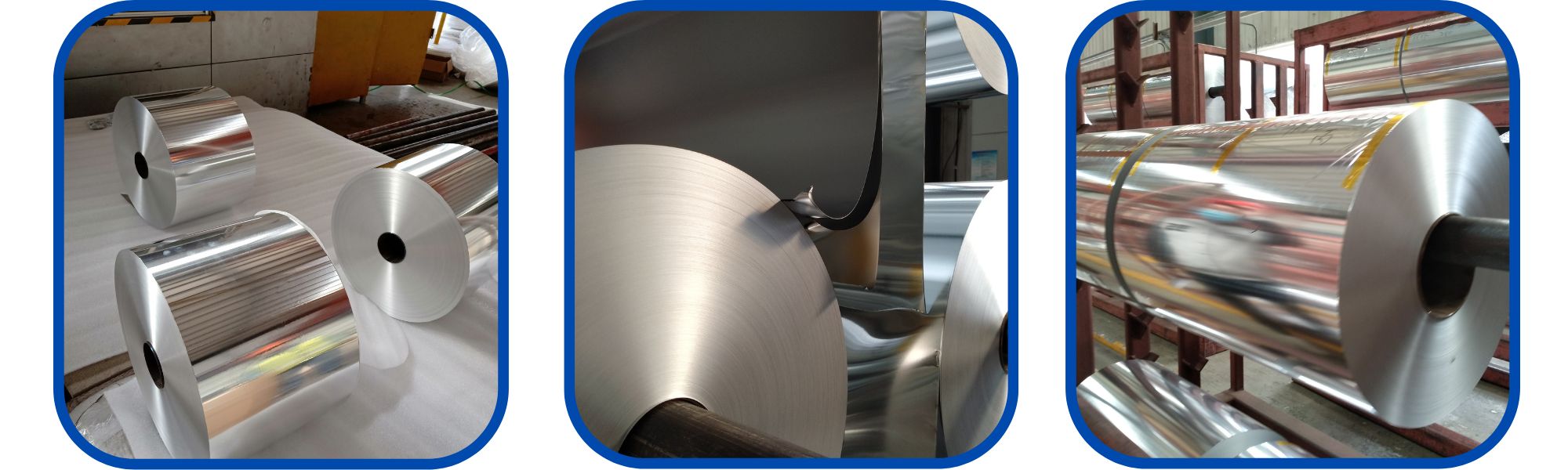

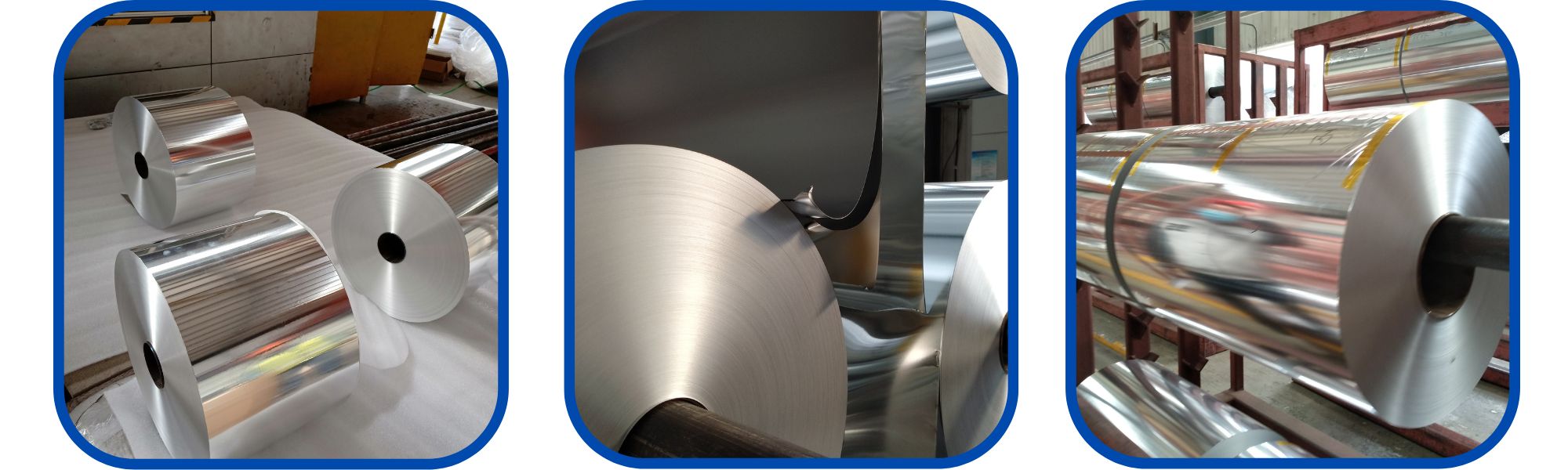

Slicing aluminum rolls: Large double side aluminum foil are cut into small rolls of suitable width, such as paper rolls.

Stamping: Use a mold to press the double side aluminum foil into the shape of the lunch box, such as making a moon cake mold.

Cutting: Remove excess scraps to avoid cutting hands.

Surface treatment (optional): Some high-end lunch boxes will be coated, anti-stick or printed with logos.

Disinfection and packaging: Finally, sterilize and package to ensure cleanliness and hygiene.

The 65 micron thickness is hard enough to prevent food from being soft and sagging, and has good sealing properties, so soup and water will not leak easily.

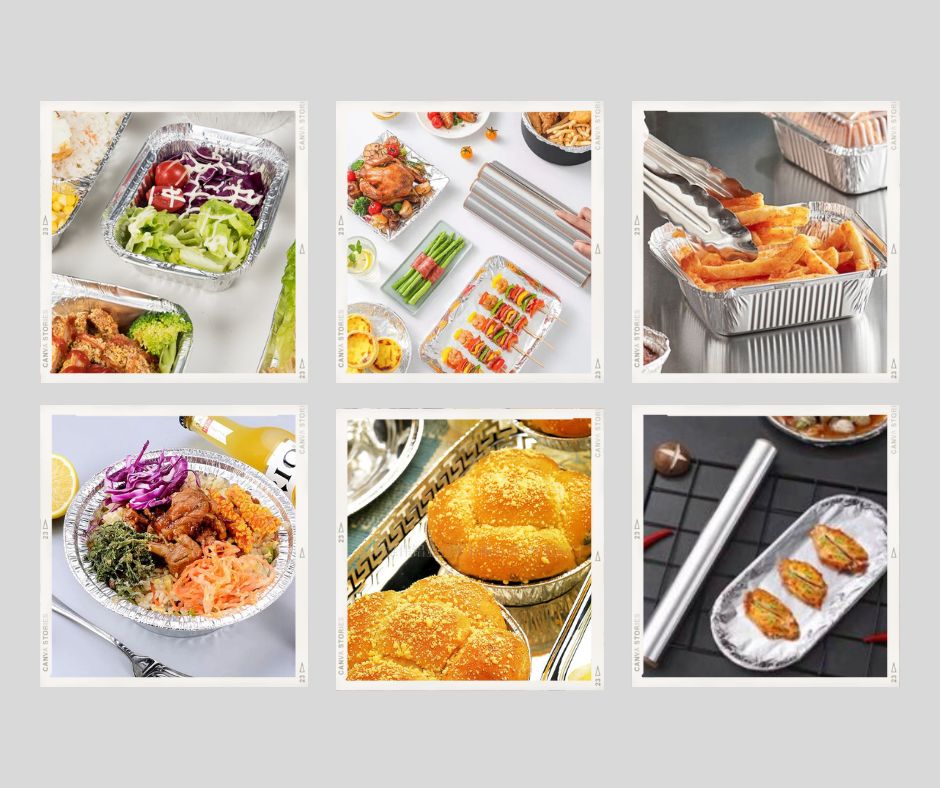

Where are 3004 Aluminium Foil lunch boxes used?

You may not have noticed, but aluminum foil container raw material have been used in many places:

Airplane meals and high-speed rail lunch boxes: Because they need to be stored for a long time, aluminum foil can keep them fresh and easy to heat.

High-end food: For example, some light salads and fitness meals look more sophisticated in aluminum foil boxes.

Pre-prepared meals: Now many semi-finished products are directly sealed in aluminum foil boxes and put into the oven, eliminating the need to change plates.

Bakery packaging: aluminum foil container raw material for cakes and pizzas can be baked directly without changing the containers.

Compared with plastic boxes, aluminum foil boxes look more "advanced" and can be directly heated without pouring them repeatedly, which is especially suitable for modern fast-paced life.

Are 3004 Aluminium Foil environmentally friendly? Can they be recycled?

Everyone is talking about environmental protection now. Plastic lunch boxes are criticized for their deterioration. What about aluminum foil lunch boxes? In fact, it is more environmentally friendly than plastic!

100% recyclable: aluminum can be melted down and reused many times. Recycled aluminum is no different from new, and the energy consumption for recycling is very low.

Will not pollute the environment: Even if it is not recycled, aluminum will not turn into microplastics like plastic in nature to pollute the soil and water.

Non-toxic when burned: if it is really impossible to recycle, burning it will not produce toxic gases (plastic produces dioxins when burned).

Of course, the recycling rate of aluminum foil lunch boxes is not high now, because many people do not know that it can be recycled and throw it away at will. If it can be recycled in a classified manner, its environmental advantages will be more obvious.

The feeling of holding an aluminum foil lunch box in your hand is completely different from that of an ordinary plastic lunch box. Its surface has a delicate metallic luster, feels cool and smooth to the touch, and emits a crisp "ding dong" sound when gently touched, giving it a high-end texture. The 65-micron thick design is just right - it is neither soft like ultra-thin aluminum foil nor bulky like a thick aluminum plate. When you open the lid, you can feel the unique elasticity of aluminum foil. The lid will bounce back a little, but it can be tightly closed to ensure that the soup does not spill out.

The design details of this lunch box are also very careful. The edges are finely curled, and they feel round and uncut; the bottom of the box is usually pressed with ribs, which not only increases the load-bearing capacity, but also makes the overall shape more beautiful. Many brands also matte the surface of the aluminum foil or print delicate logos and patterns, so that even simple lunch boxes can enhance the sense of eating ritual. What's better is that the metallic properties of aluminum foil make food insulation particularly effective. When delivering food in winter, you can open the lid and see the scene of evaporation, which is something that plastic lunch boxes can never do.

In terms of user experience, aluminum foil lunch boxes are also user-friendly. It is lighter than glass lunch boxes and more stable than plastic lunch boxes; it can be directly taken from the refrigerator to the oven, saving the trouble of changing dishes; even if there are grease stains after eating, it can be cleaned with kitchen paper. These details are gathered to form a unique user experience of aluminum foil lunch boxes, making it difficult for people to return to the era of plastic lunch boxes after using them.

The Craftsmanship Behind Aluminum Foil Lunch Boxes

Don't underestimate a small aluminum foil lunch box. Its production process contains a lot of scientific and technological content. Starting from the raw materials, food-grade aluminum alloy is selected, and after multiple rolling processes, it can reach a precise thickness of 65 microns. This thickness is determined after repeated tests - too thin is easy to break, too thick is a waste of material. In the stamping process, the temperature and pressure of the mold must be precisely controlled to ensure that the aluminum foil stretches evenly without cracking.

The most technically challenging part is the sealing process. High-end aluminum foil lunch boxes use a special lock-edge process to achieve the best bite between the lid and the box body. Some manufacturers also use food-grade adhesive strips at the seams to strengthen the seal to ensure that there is no leakage, even when the soup is filled. To improve durability, some products are also anodized to form a protective film on the aluminum surface to prevent corrosion by acidic food.

These technological improvements allow modern 3004 Aluminium Foil lunch boxes to maintain the excellent properties of the metal, while eliminating the disadvantages of traditional metal containers, which are bulky and easily deformed. Today's aluminum foil lunch boxes can be made as light as paper, yet can withstand temperatures above 200°C without deformation. It is these invisible technical feats that have allowed aluminum foil lunch boxes to move from airline catering to everyday dining tables and become the preferred packaging for high-quality food.