The core of 8011aluminum foil's ability to come into direct contact with food lies in the rapid formation of a dense, colorless and chemically inert oxide film on its surface. The film remains highly stable in food environments from pH 4.5-8.5, effectively preventing further leaching of the aluminum matrix; the oxide film will not crack or flake off, even after short periods of high-temperature baking or freezing. This alloy formulation comprises (wt%): 91.5-94.5% Al, 0.4-1.0% Mn, 0.1-0.6% Mg, with trace constituents including Si, Cu, Cr, and others. Of these, manganese acts as a hardener, while magnesium provides strength. Trace amounts of other elements may be present but will not adversely affect the stability of the foil or food safety.

Household aluminum foil designed for food contact, supplied in large industrial rolls, integrates efficient heat transfer, barrier properties against humidity, non-toxic safety features, and environmental recyclability; processing facilities subsequently convert these master rolls through precision slitting into consumer-sized rolls or pre-cut boxed sheets for global domestic applications including food preparation, storage maintenance, and thermal cooking processes. End-users can use it for wrapping and lining when baking and grilling (e.g. meat, fish, vegetables) to preserve moisture and flavor, make the heat more uniform and prevent scorching or sticking to the grill pan; it can be used for oxygen barrier preservation in cold chain storage and transportation, wrapping or covering leftover food, vegetables and fruits, bread and pastries, etc. It can be used to effectively extend the freshness period of the food by taking advantage of the excellent ability of the foil to keep out water, oxygen, light and microorganisms, preventing flavor cascading, air drying and spoilage. It can effectively extend the freshness period of food and prevent flavor, air drying and deterioration. It can also be used as the composite cover film for take-away lunch boxes and the daily grease-proof cleaning liner in the kitchen.

Aluminum foil for household has various specifications, and its thickness usually ranges from 0.008 mm to 0.03 mm, among which the ultra-thin aluminum foil of 0.01 mm is suitable for oven liner or egg tart tray, which can transfer heat quickly and provide good shaping effect for the tart during the baking process; the aluminum foil of 0.01 mm to 0.015 mm is suitable for daily wrapping of vegetables or fruits, which can be easily torn and is not easy to be broken; and the aluminum foil ranging in thickness from 0.018 mm to 0.03 mm proves ideal for high-heat applications like grilling, as it resists thermal damage, shields food from burning, and effectively contains oils and juices within the cooking area.

In terms of width, the common range of household aluminum foils is 270 mm to 600 mm. The narrower widths of 270 mm to 300 mm are suitable for small household baking trays and can be used for single-serving baking or microwave oven bowls, while the wider widths of 450 mm to 600 mm better accommodates large baking sheets or whole fish. Particularly during outdoor barbecues, it can be laid directly over charcoal grids for convenient handling and superior wrapping of bulky ingredients.

In terms of outer diameters, household foil rolls are generally available in diameters of 360 mm to 380 mm or 450 mm to 600 mm. Small rolls of 360 mm to 380 mm are suitable for daily use and are small enough to be stored in kitchen drawers, while large rolls of 450 mm to 600 mm are more suitable for household use and have a larger capacity for twice-weekly baking, lasting more than a month. In order to meet the diverse needs, we offer customized services for a wide range of applications such as home cooking and food packaging.

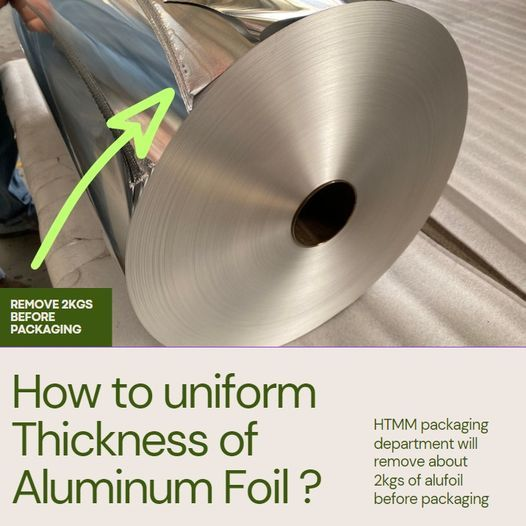

HTMM ensures stringent quality control from the very beginning by exclusively using premium 8011 aluminum alloy as its base material. Every production batch is subjected to comprehensive testing for both chemical composition and mechanical characteristics, with only those meeting strict standards proceeding to the manufacturing stage. Throughout the process, the company leverages advanced technology and highly automated equipment. Multiple monitoring points on the production line enforce strict online inspection of semi-finished and finished products, ensuring process stability and product quality control. Final products undergo comprehensive inspection before shipment to guarantee reliability. Furthermore, the company implements green production principles, utilizing eco-friendly equipment to reduce energy consumption and emissions. This ensures products meet both food safety requirements and eco-compliant standards. HTMM's reliable quality and service have made its products popular globally, earning an excellent reputation and fostering long-term partnerships. The company values customer feedback and continuously optimizes products and services to enhance satisfaction.

HTMM aluminum foil products meet export standards and are packaged in free-fumigated wooden boxes, which can effectively prevent goods from being damaged during transportation. The company offers two types of packaging for customers to choose from: suspension packaging and horizontal packaging. Typically, an 18-22 ton load fits a 1×20ft container, while a 20-24 ton load fits a 1×40ft container. Each wooden case weighs 0.5MT-1MT, up to customer's request.

.jpg)

HTMM forges quality with craftsmanship and leads the future through technology. Its Household Aluminum Foil 8011 Jumbo Rolls for Food Contact embody a relentless pursuit of "safety, reliability and excellence" in every stage: from selecting high-purity raw materials, through precision rolling and annealing processes, to stringent online and offline quality inspections, and professional protective packaging. A comprehensive system of internationally recognized certifications not only affirms the exceptional quality of our products but also provides global customers with a solid confidence guarantee.