30 Micron Aluminium Foill is a ubiquitous material in manufacturing and industrial processes due to its lightweight, high durability, corrosion resistance, and formability. Thinner gauges of30micron Aluminium Foil (1.2 mils) are particularly well-suited for applications involving 30micron Aluminium Foil lamination techniques. This article will provide an in-depth look at the key properties and industrial uses of 30 micron 8079 Aluminum Foil.

What is 30 Micron 8079 aluminum foil?

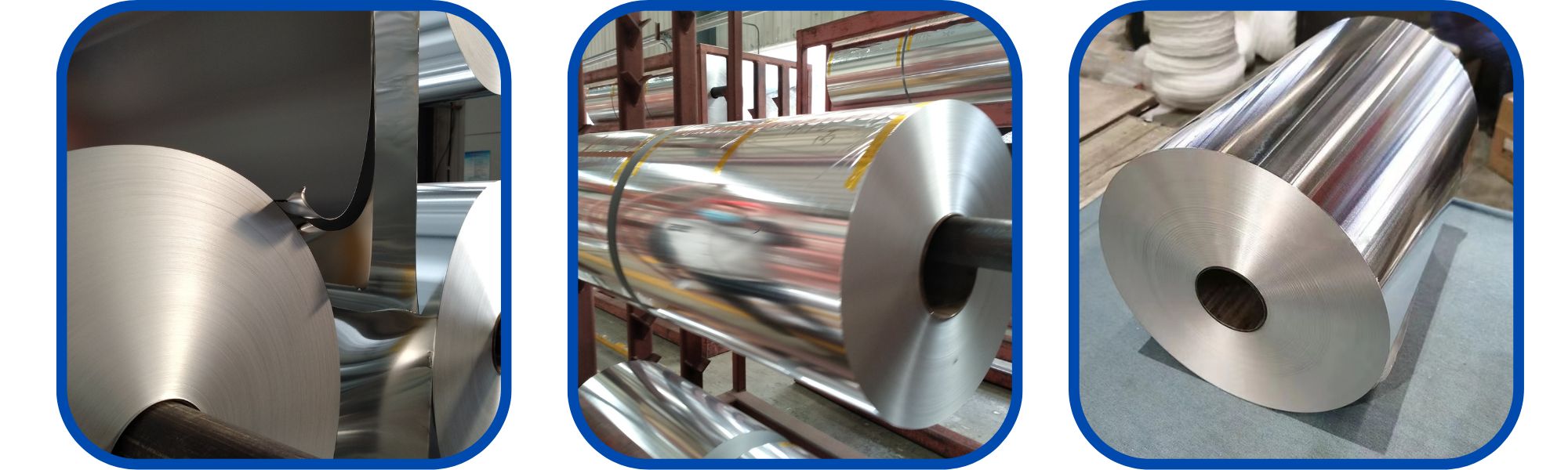

30 Micron alu foill is produced by passing aluminum sheets between polished rolls to reduce the thickness. Gauge is the standard global measurement for foil thickness, with one micron (μm) equal to 0.001 millimeters or 0.000039 inches.

30 Micron alu foil refers to aluminum that has been rolled down to a thickness of 0.030mm or 0.0012 inches (1.2 mils). On the gauge scale, this equates approximately to a 3 gauge Alu foil for lamination thickness. At this ultra-thin dimension,Alu foil for lamination retains the key attributes of bulk aluminum yet gains enhanced flexibility and conformability ideal for foil lamination processes.

Properties of 30 Micron Aluminum Foil

Lightweight - Weighing only 1/10th as much as heavier gauges per square foot, 30 micron foil imparts minimal additional weight to laminated materials.

Flexible - The very thin gauge allows 30 micron foil to conform to complex contours, seams, and crevices during lamination without cracking or tearing.

Formable - It can be easily stamped, stenciled, die-cut or hot stamped during composite material production runs.

Corrosion Resistant - 30 micron foil still forms the protective aluminum oxide surface layer preventing rust formation even in thin gauge.

Heat Reflective - Its high thermal conductivity reflects over 80% of infrared radiation for applications requiring heat shielding properties.

Chemical Inertness - Aluminum resists degradation from exposure to alkalis, acids and other industrial chemicals.

Conductive - Excellent electrical conductivity at this gauge enables electrostatic applications.

Recyclable - Foil scrap can be recovered and remelted for reuse with minimal reprocessing costs.

These material attributes make 30 micron aluminum foil perfectly suited for applications involving the lamination and integration of foil onto or between other substrates. Its robustness in thin gauge expands usage options.

Aluminum Foil 30Micron Lamination Processes

Several industrial lamination techniques integrate 30 micron aluminum foil into composite materials:

Roll Lamination - Foil is fed continuously between hot rolls with an adhesive or polymeric film to bond onto paper, plastic or fabric substrates for moisture barrier properties.

Flat Bed Lamination - Sheets or continuous webs pass through heated platens applying even pressure to fuse layers together. Offers more containment of volatile emissions.

Autoclave Lamination - Applying heat and higher pressures cures thermoset adhesives for very high bond strengths required in composites like aircraft panels.

Co-extrusion Lamination - Combining multi-layer extrusion with a separate foil feeding line embeds foil within plastic sheeting in a continuous process.

Stitch/Seam Lamination - Used in textiles, ultrasonic or sewing stitches hold layers together during thermal bonding for breathability in sports apparel.

Cold Lamination - Does not require heat activation, ideal for delicate or heat-sensitive substrates like paper or foams using contact or pressure-sensitive adhesives.

The flexibility of 30 micron foil allows it to smoothly conform to other substrates through these lamination techniques without defects, yielding durable foil-composite materials for industrial applications.

Aluminum Foil 8079 Common Lamination Applications

Barrier Packaging Films - Extends shelf-life of food, pharmaceuticals and consumer products through oxygen, odor and moisture blocking.

Printing - As a dead soft substrate for gravure, flexographic and digital printing before conversion to other end products.

Construction Materials - Reinforces asphalt-impregnated roll roofing and adds a vapor barrier in housewraps under siding.

Industrial Films - Used as spark-resistant barriers, static dissipative layers, X-ray shields and EMI shields in equipment and electronics manufacturing.

Transportation - Core material for auto body panels, aircraft glazing skins and boat/RV construction requiring rigidity and dent-resistance.

Appliances - Provides scratch protection, wireless charging abilities and heat reflectivity in household appliances and small kitchen appliances.

Batteries - Current collecting foil laminated with polymer separator materials in lithium-ion cells require ultra-thin gauge 30 micron aluminum.

Medical Products - Embedde as a sterile barrier or strength layer in diagnostic test strips, wound dressings, and transdermal drug delivery patches.

The superior conformability of 30 micron aluminum foil makes it well-suited for a diverse range of lamination applications across multiple industries. Its formability enables foil integration onto complex substrate geometries during mass production.

8079 Aluminum Foil Packaging Applications

►Food Packaging Lamination

Milk Cartons - 30 micron foil laminated to paperboard forms an effective vapor and grease barrier protecting nutrition of aseptically packed milk, cream and juice cartons.

Frozen Food Trays - Foil-coated paperboard or plastic trays for meats, vegetables and prepared meals maintain freshness without freezerburn in the microwave, oven or skillet.

Chip Bags - Metallized films extruded with an internal 30 micron aluminum foil layer provide effective oxygen and moisture barrier to boost chip crispness on the shelf.

Cracker Sleeves - Cookies, nuts and other shelf-stable snacks packaged in foil-laminated paper sleeves or pouches maintain crunch and freshness long-term.

Blister Packs - Pharmaceuticals and small consumer goods are sealed within thermoformed clear plastic clamshells with a backing of aluminum foil for tamper-proof protection during storage and display.

Medical Packaging

Test Strips - Enzyme-detecting biochemical test strips for glucose, cholesterol and pregnancy testing are bonded to 30 micron aluminum carrier foil for rigidity, reflectivity and mass production handling.

Wound Dressings - Non-woven polymer fabrics are laminated to an aluminum polyester film for forming breathable, sterile and disposable dressings able to be cut readily by medical staff.

Transdermal Patches - Thin film polymer matrices containing drugs like nicotine or hormones are sealed within aluminum backing laminates controlled releasing through the skin.

Other Uses

Tobacco Packs - Cigarette and cigar packages contain an internal moisture barrier of 30 micron foil between paper wraps or outer plastic overwrap films.

Tea/Coffee Packets - single-serving portions of instant drinks packaged in foil laminated paper sachets or pouches maintain freshness without need for resealing between uses.

The formability and barrier properties of 30 micron foil make it ideal for providing shelf-stability, tamper-proof protection and freshness retention within various medical and food lamination packaging applications. Its recyclability is also an environmental plus.

►Consumer Product Applications

Appliance Lamination

Refrigerators - Interior refrigerator walls are lined with painted or printed aluminum foil for a durable, easy-to-clean and highly heat reflective surface improving energy efficiency.

Ovens - The internal cavity is often fitted with a laminated layer of 30 micron aluminum foil beneath a porcelain enamel coating on steel for superior heat conduction allowing rapid preheating.

Toasters - Exposed heating elements are encased within a foil laminate for safety while reflecting maximum heat upward toward the bread slots.

Cooktops - Gas or electric stove top surfaces feature a layer of 30 micron foil bonded under glass-ceramic or cast iron for an attractive encapsulated finish.

Microwaves - The interior walls of microwave ovens are commonly foil lined to reflect electromagnetic waves for more efficient cooking using less power.

Consumer Goods Lamination

Flashlights - 30 micron aluminum foil serves as a conductive surface beneath polymer films in cylindrical or square battery cases for wireless/inductive charging functionality.

Electronics - Notebooks, desktops and gaming equipment employ laminated aluminum heatsink panels, heat spreaders or wireless charging pads to pull heat away from internal components.

Auto Accessories - Rear window sunshades, visor vanity mirrors and license plate frames are metallized by foil lamination for heat reflection and scratch resistance as trim pieces.

The excellent conductivity, reflectivity and durability of 30 micron aluminum foil make it ideal for integrating essential functional layers within home appliances and consumer products requiring heat management or wireless power. Its formability enables complex geometries.

►Industrial Uses

Construction Materials

Roofing - Aluminum foil is laminated to asphalt saturated felt or paper to form highly reflective and waterproof rolled roofing membranes for durability in commercial buildings.

Siding - An outer layer of 30 micron aluminum foil applied to housewraps provides a secondary weather-resistant barrier beneath siding materials like stucco or brick veneer.

Insulation - Foil-faced polyisocyanurate and polystyrene insulation boards reflect radiant heat for high thermal resistance values important in cold storage, metal buildings and attics.

.jpg)