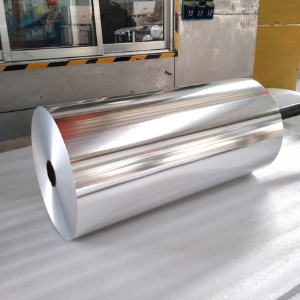

The 1235 Aluminum foil jumbo roll is an excellent choice for companies using flexible packaging machinery. The 12 Micron Aluminum Foil thickness provides strong barrier protection without being too thick or hard to work well on high-speed packaging lines. At 1235mm wide and 3000mm long, the extra large roll provides maximum production and uptime with reduced changes compared to smaller rolls. The generous width allows for seamless packaging of different materials. The roll has a sturdy 6-inch plastic core that resists crushing under heavy dispensing loads. This keeps the foil tight and wrinkle-free to ensure smooth feeding through the machinery without the risk of jamming or breakage. At 1235 aluminum foil 12 Micron Aluminum Foil, it molds tightly and cleanly around production of all contours without splitting or distortion.

The 1235 Aluminum foil jumbo roll is an excellent choice for companies using flexible packaging machinery. The 12 Micron Aluminum Foil thickness provides strong barrier protection without being too thick or hard to work well on high-speed packaging lines. At 1235mm wide and 3000mm long, the extra large roll provides maximum production and uptime with reduced changes compared to smaller rolls. The generous width allows for seamless packaging of different materials. The roll has a sturdy 6-inch plastic core that resists crushing under heavy dispensing loads. This keeps the foil tight and wrinkle-free to ensure smooth feeding through the machinery without the risk of jamming or breakage. At 1235 aluminum foil 12 Micron Aluminum Foil, it molds tightly and cleanly around production of all contours without splitting or distortion.Smooth, bright surfaces enhance branding visibility and consumer appeal on shelves. Food manufacturers appreciate consistently superior performance compared to thick or thin foils. Quality is assured through strict suppliers with strict protocols for monitoring raw material sourcing, production consistency, and delivery specifications. Strength and barrier tests test the integrity of safety for perishables, snacks, frozen foods and other items. Proven compatibility for form fill seals, flow wrappers, and other flexible packaging equipment typically operated at speeds in excess of 200 packages per minute. The ability to load the huge roll directly onto the line maximizes operating time between changeovers versus occasional smaller rolls.

Sustainability is also a factor in its favour. aluminum foil for flexible packaging is 100% recyclable and this supplier uses post-consumer scrap in the production of primary products. The sheer scale of the 1235mm x 3000m jumbo roll reduces packaging, storage and transport waste compared to smaller sizes. Given the infinite recyclability of aluminum without losing its properties, the foil can be constantly remelted and reshaped, minimizing environmental impact. Overall, the extra large 1235 aluminum foil for flexible packaging at 12 Aluminum Foil for lamination gauge provides flexible packaging producers with an excellent combination of performance, efficiency and eco-friendliness for high-speed operations.

The 1235 aluminum foil 1235mm width Aluminum Foil for lamination of the Jumbo Roll allows for packaging versatility in different line configurations. Whether loaded horizontally or vertically, the wide foil saves space on the unwinder and accommodates a variety of material sizes without waste. It can form sandwich or bag seals, tray covers or pouches, all on the same tool by simply adjusting the die and seal. The aluminum foil for flexible packaging thickness strikes a perfect balance for most applications too - thin enough to wrap contours cleanly yet enough to reliably form a seal over distribution pressure.

Quality is a mark of the manufacturer. Domestically sourced from post-consumer scrap using only water power, purity exceeds 99.5%. The foils are physically tested to exceed 1 km roll without missing a pinhole. Printed batch codes enable full traceability. Despite simulating aggressive abuse, the aluminum foil for flexible packaging maintained seal strength above industry standards. Customers appreciate reliable quality Preserves brand reputation.

Sustainability extends to end-of-life management. The manufacturer takes back scrap and unused jumbo rolls for remelting, and provides recycling instructions. Curbside programs keep aluminum circulating forever without downcycling. Its durable packaging protects perishables from farm to home while having the lowest embedded greenhouse gas emissions of any foil. The overall 1235mm x 12 Micron aluminum foil jumbo roll for flexible packaging sustainably optimizes the efficiency and safety standards of the flexible packaging line.

The flexibility of the 1235 Alloy jumbo roll allows it to be run on many different types of packaging machinery. It has been proven to run well on form fill seal baggers, flow wrappers, band sealers, leaders, thermoformers and other vertical or horizontal packaging machines. Wide, wrinkle-free foil delivers smooth and consistent high-speed delivery without breaking or shifting, which is important for maintaining production on high-speed lines. It is also suitable for horizontal form fill seal machines, which are commonly used for stand-up pouches and bagmaking. The 12 micron gauge is ideal for these applications, providing adequate rigidity for processing yet optimizing to create an attractive closed package.

Technical support from the manufacturer guarantees optimum performance. Their experts visit customer sites to observe line trials, recommend Unwinder setups, and fix any occasional problems. Most questions can be answered over the phone through their responsive technical support team. Precision assistance helps customers achieve productivity goals using jumbo rolls. Independent testing further verifies claims, building confidence in the product. Overall, extensive support helps ensure packaging lines sustainably achieve their throughput targets using high-quality 1235 mm wide and 12 micron aluminum foil jumbo roll for flexible packaging thick rolls.

The 1235mm width of the jumbo foil roll provides flexibility in line design that may not be possible with smaller rolls. The wide foil can be run in a landscape orientation, allowing taller pouches or bags to be built compared to stacking multiple narrow foils. This maximizes the use of vertical space within the machine. It can also be loaded vertically, saving floor space. With the jumbo roll running continuously, the changeover only requires pushing empty cores out and full ones in, taking only minutes versus longer stops for smaller roll changes. Less wasted speed improves uptime.

Quality and reliability are further ensured through careful production control. The aluminum coils pass raw through inline slitters to produce foil meshes. The tension is maintained throughout the underside electrodeposition, drying, and rolling. Meticulous inspection also detects microscopic variations in gauges or brakes. The rolls are carefully rolled, wrapped in plastic, labeled and easily identifiable. Finished products are lab tested on standard procedures to prove durability for rigorous warehousing and distribution cycles. Certifications such as ISO 9001 affirm a commitment to consistently meet customer requirements. Food safety is a top concern addressed through packaging integrity and supply chain due diligence.

For a width of 200mm-1500mm, the maximum yield is obtained from each roll. Operators do not have to piece together multiple narrow foils to cover wide trapeckers or to form fill lanes. This removes incomplete SIMs that may jeopardize package security. The rigidity of the 6-inch plastic core keeps the foil flat on the unwinder for wrinkle-free distribution even under heavy loads. High-capacity wrappers and flow wrappers can run for an hour or more before a core change is required compared to several constraints with smaller cores. Less downtime means more throughput.

Quality and packaging science ensure consistent barrier protection. Advanced metallization bonds the aluminum layer uniformly with no defects that could compromise the seal or allow pinholes. Laboratory tests demonstrate that oxygen and moisture barriers greatly exceed control requirements. Packages maintain a safe and fresh closing environment during long distribution cycles. Advanced E-beam and IBC sterilization treatments are available for applications such as prepared foods that require commercially sterile barrier packaging.

The manufacturer’s commitment to sustainability doesn’t stop at using renewable energy and post-consumer scrap. They work closely with customers to implement lean practices that reduce waste throughout the supply chain. Optimization studies recover inches of excess overwrap or convert leftover foil into rolls for secondary packaging use. Materials are either recycled or upcycled to add value. The overall high performance yet economical 1235 Aluminum Foil jumbo foil roll minimizes environmental impact while increasing manufacturing productivity.