China’s leading micron foil producers strategically locate manufacturing facilities near ports to meet rapid orders. Online ordering systems integrate smoothly with purchasing databases. Bonded warehouses consolidate shipments reducing freight costs. Technical experts recommend special tests that develop innovative use protocols. Comprehensive certifications covering food safety, sustainability and labor standards guarantee the buyer a reliable partner.

Manufacturers prioritize quality through relentless process optimization. Sophisticated slitters minimize thickness variations. Testing labs accept random samples in conditions that exceed international specifications. Certifications such as ISO 9001 verify adherence to controls. Blockchain traceability provides complete transparency. Field testing evaluates customized solutions that meet emerging regulations. Technical centers pioneer new barrier coating and laminate formulas.

Sustainability initiatives include the use of renewable energy, zero waste programs and applied research projects. The detailed report quantifies strategies that address climate change, worker safety and the circular economy. The partnership examines applications that help other industries transition to more sustainable practices.

China’s micron aluminium foil manufacturing expertise coupled with integrated supply chain management positions it as the ideal sourcing partner supporting innovation worldwide. Ongoing product development ensures this versatile substance nourishes the population in an affordable way for generations to come.

Micron foil producers in China emphasize continuous technological advancement. The state-of-the-art slitter tailors widths below 10 microns with micron-level precision for biomedical applications. Pilot Production tests metallization techniques by depositing very thin barrier coatings without compromising softness. New processes combine the mechanical strength of aluminum with the functionality of polymers to form better laminate composites. Successful prototypes upscale quickly to meet commercial production volumes.

Customization capabilities power a variety of applications. Special thickness grades and surface treatments optimize shelf-life extension for a variety of perishables. Tailored surface energy properties and controlled vapor convection barriers open new packaging frontiers. Digital printing attaches variable images without the limitations of legacy lead stock formats. The sample shipment evaluates micron foil solutions that enhance affordable global health and food conservation.

Collaboration leads to innovation by addressing sustainability priorities. Roundtables involve the application of nanotechnology in composite formulations using recycled materials by leading technical schools. Government-industry partnerships accelerate emerging technologies that separate foil streams within facilities for closed-loop production. University projects revealed new microalloying techniques that further optimize barrier integrity. Through open collaboration, Chinese manufacturers reinforce the role of aluminum foil nourishing the global population in a responsible way for generations.

Quality assurance underpins the reliability of micron aluminium foil through precise testing that exceeds international standards. Accelerated aging tests examine long-term barrier properties that resist permeability under thermal stress. Headspace analysis ensures optimum gas transmission rates while maintaining freshness. Impact and compression resistance ensure durability through distribution. There is no detectable chemical migration when exposed to sensitive materials. Nanoscale inspection even detects atomic imperfections. ISO and FDA certification requires adherence to stringent regulations that maintain vital consistency for medical and food packaging.

The sustainability commitment aims to optimize the environmental profile of micron foil. Most major generation facilities generate surplus renewable energy locally from solar and hydro sources. Post-industrial scrap is recycled internally to a 95% purity level through new AI-guided sorting. R&D progress led to the release of new microalloying techniques that incorporated more than 60% recycled materials as well as enhanced barrier function. Quantifying annual impacts through standardized frameworks leads to continuous improvements on efficiency, water management and sourcing of sustainably produced inputs. Membership in international organizations facilitates the harmonization of standards on circular priorities.

Education initiatives increase cultural understanding of the technical merits of aluminum compared to petroleum alternatives. University incubators help student entrepreneurs leverage micron foil to address unmet needs. The interactive science exhibit demonstrates its critical yet often invisible role in securing global health and access to nutritious food. Policymaking forums provide a collaborative platform that identifies science-based solutions that overcome barriers to sustainable production and end-of-life management. Together, the outreach empowers communities around the world to leverage this critical commodity responsibly. Chinese manufacturers play a leading role in ensuring that Micron aluminum foil provides affordable and consistent nutrition to the population for generations to come.

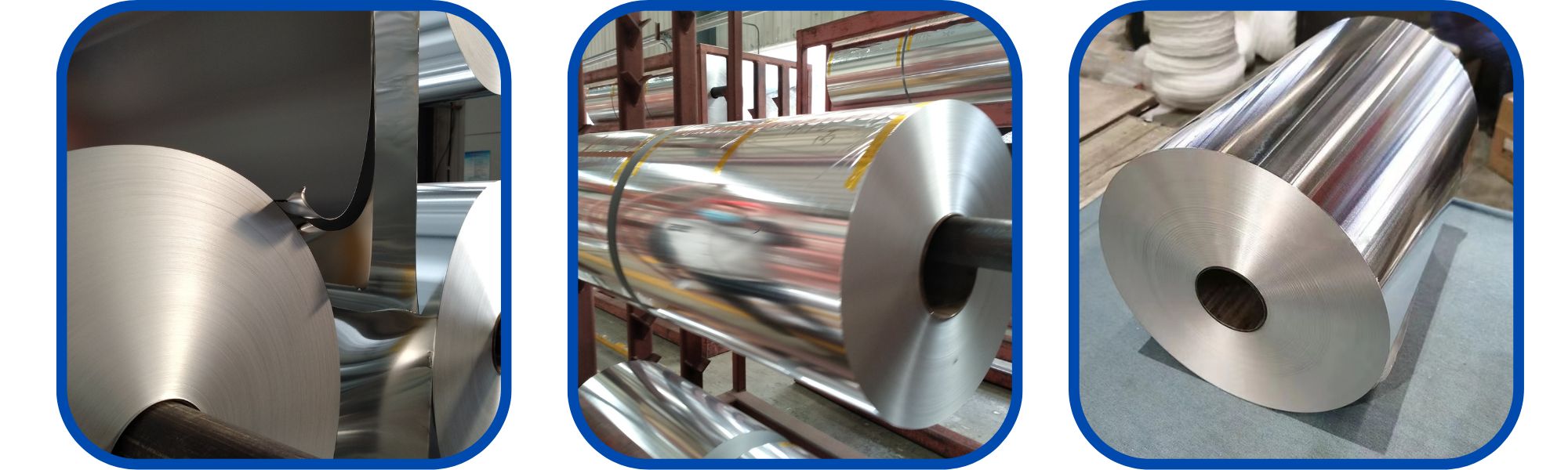

China’s expertise in micron foil production enables reliable, cost-effective solutions in a spectrum of gauges. The wide master coil allows widths as low as microns for flexible packaging applications requiring very low oxygen permeation rates. with levels of barrier and hardness suitable for food and flexible packaging storage between 10-30 micron grades. The 6-50 micron wide foil addresses typical industrial uses demanding high tensile strength and flexibility. This extensive product range opens up huge opportunities for innovative applications that improve global access to healthcare and nutrition.

Quality assurance is intrinsic to reliability through strict control. Raw material traceability provides complete transparency from the primary aluminum smelter to the finished product. Factory certification mandates real-time process monitoring ensuring ultra-precise slit widths. Robotic handling eliminates the risk of contamination. Test random samples under conditions exceeding international standards that test stability under abusive shipping and prolonged use. The data ensures performance by protecting even oxygen-sensitive materials.

Sustainability priorities strengthen over time. Solar panels provide carbon-free power to major manufacturing facilities. The internal scrap recycling loop recycles 95% of the process waste. Consortium projects open new metallization techniques that enable even thinner gauge constraints without including function. Blockchain integration tracks environmental footprint reduction.

Education spreads understanding. University partnerships cultivate applied research exploring the frontiers of biomedicine and nanomaterials. Mentorship leverages the protective properties of micron foil to inspire entrepreneurial problem solving. Advocacy networks promote their often invisible yet important role by facilitating access to global health and nutrition.

Clearly, the Chinese suppliers’ expertise and commitment to quality, sustainability and social progress support innovative solutions for generations to come, cementing the essential role of micron aluminium foil.