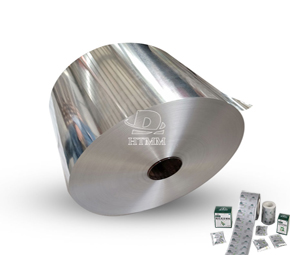

Now that aluminum foil bags have a big market, how do you choose aluminum foil bags? Aluminum foil packaging bags have good barrier properties, high heat sealing performance, good moisture resistance and high transparency. And acid resistance, wear resistance and other functions are also very good, so it is widely used in the food industry packaging bags. Nowadays, packaging bags are getting more and more people's attention. How to choose packaging bags, we need to pay attention to the environmental protection of printing equipment and machinery. Does not produce harmful gases, odors and liquids. The production process is non-polluting and free of any harmful substances.

Try to use materials that are not coated or coated. Colored plastic bags cannot be used for food packaging. These aluminum foil bags are often made from recycled plastic. Food packaging bags are not smelly, odor-free, and have a special smell of plastic packaging bags, which cannot be used for food packaging.

Vacuum bags need to check the appearance of their bags. The visual inspection mainly depends on whether the packaging bag has obvious scratches; whether there are pinholes; whether there is pollution; whether the sealing is standardized. Test for compressive strength and burst strength. The method of strength and breaking strength is to use a heavy object extrusion method, put the packaging bag on the table top, and then add a heavy object thereon, and after one minute, the vacuum packaging bag first appears to be invisible, leaking, and the like. When selecting materials, we should use environmentally friendly materials, pay attention to the recyclability of aluminum foil packaging materials, green materials, and do not use secondary waste, especially food packaging bags do not use industrial waste or recycled materials.

Aluminum foil packaging provides a solution to food waste, ensuring food preservation, so that we can enjoy and taste the original taste. The longer the food preservation period, the less waste it will be; it is not only conveniently integrated into our lives, but also protects our environment and our future.

As the first brand in the aluminum processing industry, HTMM produces aluminum foil in line with national standards and wins customer satisfaction. At present, it can provide 1235 aluminum foil alloy for food manufacturing enterprises, and O-package aluminum foil. On the basis of the guaranteed version and the quality of the layout, black oil spots, bright lines, roll marks, small black wires, scratches and bumps are eliminated. Problems such as the addition of mosquitoes appear. We guarantee that the finished product thickness should be controlled within ±4%. Relying on mature packaging technology, the perfect transportation system ensures that the process from the factory to the delivery of the customer avoids oxidation.