How to choose the right aluminum foil roll?

As a common packaging material, aluminum foil rolls are widely used in food, medical, construction and other fields. When purchasing aluminum foil rolls, it is crucial to choose the right product because different aluminum foil rolls have different characteristics and uses. So how to choose?

First of all, choosing a suitable aluminum foil roll needs to be considered according to the field of use. Different industries have different requirements for aluminum foil rolls, such as the alloy state, width, thickness and inner and outer diameters of the aluminum foil. Therefore, you must first establish the primary use of the aluminum foil roll that you require. For instance, if you need to use aluminum foil rolls for food packaging, make sure to select food-grade aluminum foil rolls so that they may safely come into touch with food and have good moisture-proof, gas-proof, and freshness-preserving features. Choose a product with good heat and sound insulation qualities if you need to employ aluminum foil rolls in the building industry.

Second, think about the aluminum foil roll's thickness and durability. The endurance and usefulness of the aluminum foil roll are determined by its thickness. While smaller foil rolls are typically used to cover lighter goods, thicker foil rolls are typically tougher and suited for shielding heavy items. The aluminum foil roll's strength is also a crucial factor to take into account. High-strength materials should be used if you need to fold or compress aluminum foil rolls during shipping to prevent breakage and distortion.

Third, think about aluminum foil rolls' barrier qualities. One of the key factors in the widespread usage of various aluminum foil rolls in food and pharmaceutical packaging is their superior barrier capabilities. Because different rolls of aluminum foil have varied barrier qualities, you should pick the right one based on how much freshness and protection your package requires. For long-term food or water preservation, for instance, you may need to use aluminum foil rolls with greater barrier qualities.

It's also critical to take aluminum foil rolls' processing characteristics into account. Because aluminum foil rolls are frequently used to package foods, it is crucial that they are simple to cut, fold, and wrap. To make sure that the aluminum foil roll you choose can fulfill your manufacturing objectives, you should be aware of the product's processing capabilities.

Finally, you should also consider the quality assurance and supplier reputation of your aluminum foil rolls. Choosing a supplier with a good reputation and formal qualifications can ensure that you buy high-quality aluminum foil rolls. In addition, it is also important to know the supplier's after-sales service and technical support. There are many aluminum foil factories in China, such as Henan Tengdeli Metallurgical Materials Co., Ltd., which has specialized in aluminum foil for more than ten years, and has also been engaged in import and export trade for ten years. The global sales volume is very large, only because of its good quality. The cost-effectiveness is high, so it is widely liked by consumers.

Raw material and making process of aluminum foil coil

Before producing aluminum foil rolls, the aluminum material needs to be prepared. Commonly used aluminum materials are aluminum alloys or pure aluminum, which can be prepared by cutting and trimming from raw materials.

Smelting and Casting: Aluminum material goes through a process of smelting and casting that converts it into aluminum blocks. This process is usually carried out in a special melting furnace, where the aluminum material is heated to a high temperature to melt, and flows from the furnace into a mold by gravity or pressure.

Sheet rolling: After the aluminum block is preheated, it is rolled through a multi-track continuous rolling mill. It needs to go through three procedures of rough rolling, intermediate rolling and finishing rolling.

Cold rolling: After hot rolling, the thin plate needs to be cold rolled to improve the surface quality and flatness of the plate. In this process, the plate is sent to the cold rolling mill and cold rolled by the pressure of different roller tables.

Coating treatment: The thin plate after cold rolling needs to be coated to improve its corrosion resistance and oxidation resistance. To achieve the purpose of complete degreasing.

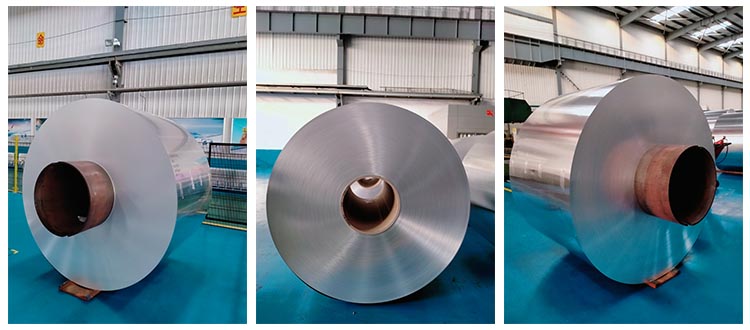

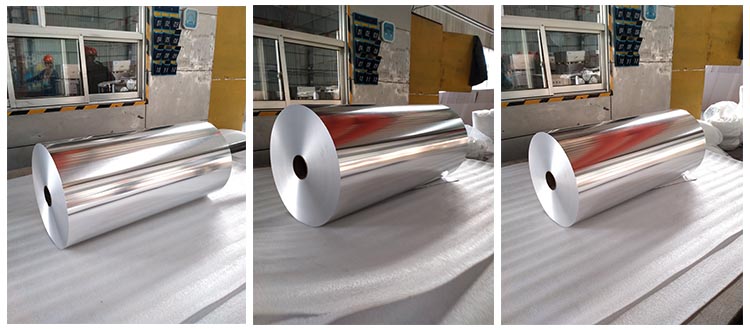

Shearing and coiling: The coated sheet is sheared by a shearing machine to cut it into the required size. The sheet is then passed through a winder that winds it into a larger curled shape to form a roll of aluminum foil.

Inspection and packaging: The rolled aluminum foil needs to undergo strict quality inspection to check whether its surface quality, coating firmness and other indicators meet the requirements. Qualified aluminum foil will be marked and packaged accordingly for storage and transportation.

How to store aluminum foil ?

Aluminum foil rolls are a common packaging material that is widely used in food, pharmaceutical and industrial fields. Proper storage and care of aluminum foil rolls can prolong their life and ensure their performance and quality.

First of all, when storing aluminum foil rolls, you should choose a dry, ventilated, and non-corrosive gas environment. Generally speaking, aluminum foil rolls are sensitive to humidity. If stored in a humid environment, it is easy to cause oxidation, air leakage or deformation of the roll.

Second, care should be taken when storing aluminum foil rolls to avoid friction with other items or heavy pressure. If rubbed or subjected to excessive pressure, the protective layer may be damaged resulting in scratches or nicks on the surface of the aluminum foil roll. Therefore, care should be taken to avoid friction with other items during storage, and keep the coils stored horizontally to avoid excessive pressure.

Third, avoid exposure to direct sunlight. Ultraviolet rays in sunlight will have certain effects on aluminum foil rolls, which may cause color changes, surface oxidation or quality degradation.

The method of maintaining aluminum foil rolls mainly includes regular cleaning and inspection. You can use a soft, damp cloth to gently wipe the surface of the roll of aluminum foil to remove dust and stains. Try to avoid wiping with hard or sharp objects, so as not to scratch the surface or damage the protective layer.

Finally, be careful with the proper handling and use of aluminum foil rolls. When using aluminum foil rolls, follow the relevant operating guidelines and safety regulations to ensure proper use and protection.