8011 Aluminium foil is aluminium prepared in thin metal leaves with a thickness less than 0.2 mm; thinner gauges down to 6 micrometres are also commonly used.Standard household foil is typically 0.01-0.018 mm thick.The foil is pliable, and can be readily bent or wrapped around objects. Thin foils are fragile and are sometimes laminated to other materials such as plastics or paper to make them more useful.

8011 Aluminium foil is aluminium prepared in thin metal leaves with a thickness less than 0.2 mm; thinner gauges down to 6 micrometres are also commonly used.Standard household foil is typically 0.01-0.018 mm thick.The foil is pliable, and can be readily bent or wrapped around objects. Thin foils are fragile and are sometimes laminated to other materials such as plastics or paper to make them more useful.

8011 Aluminium foil is produced by rolling sheet ingots cast from molten billet aluminium, then re-rolling on sheet and foil rolling mills to the desired thickness, or by continuously casting and cold rolling. To maintain a constant thickness in aluminium foil production, beta radiation is passed through the foil to a sensor on the other side. If the intensity becomes too high, then the rollers adjust, increasing the thickness. If the intensities become too low and the foil has become too thick, the rollers apply more pressure, causing the foil to be made thinner.

Due to perfect anti-moister, anti-pollution and electrical conductor characteristics with blare feature, the 8011 aluminum foil has been available for packing field, capacitor making field, construction field, ornament field, printing field and household packing, the main products of HTMM company as follows: cigarette foil, golden foil paper, food foil, capacitor foil, medical foil, beer foil, housing foil and soft packing foil for aluminum foil manufacturer.

Advantage to the performance of 8011 Aluminum Foil

8011 Aluminum foil is a versatile material commonly used in packaging, construction materials, and industrial applications. It contains a small amount of manganese, about 1.5%, which improves its performance compared to higher purity foils. The enhanced formability of 8011 aluminum foil makes it easy to bend, shape, stamp, and otherwise in a variety of configurations during the manufacturing process. Whether drawing foil into complex packaging elements or shaping foils for siding and signage, the addition of manganese allows 8011 to more easily take on desired geometric forms.

Another advantage to the performance of 8011 aluminum foil alloys is that they can better withstand repeated shaping and even possible downstream recycling or remanufacturing throughout the production cycle of a product. Products made from 8011 foil maintain their integrity through multiple forming steps. Its strength is resilient to the mechanical stresses associated with shaping without cracking or tearing as easily as some high-purity foils. The strong performance of 8011 aluminum results in many applications beyond packaging such as building materials, automotive components, heating and cooling equipment screens, decorative home appliances and more. This provides reliable performance in any application where aluminum is formed in a specific configuration.

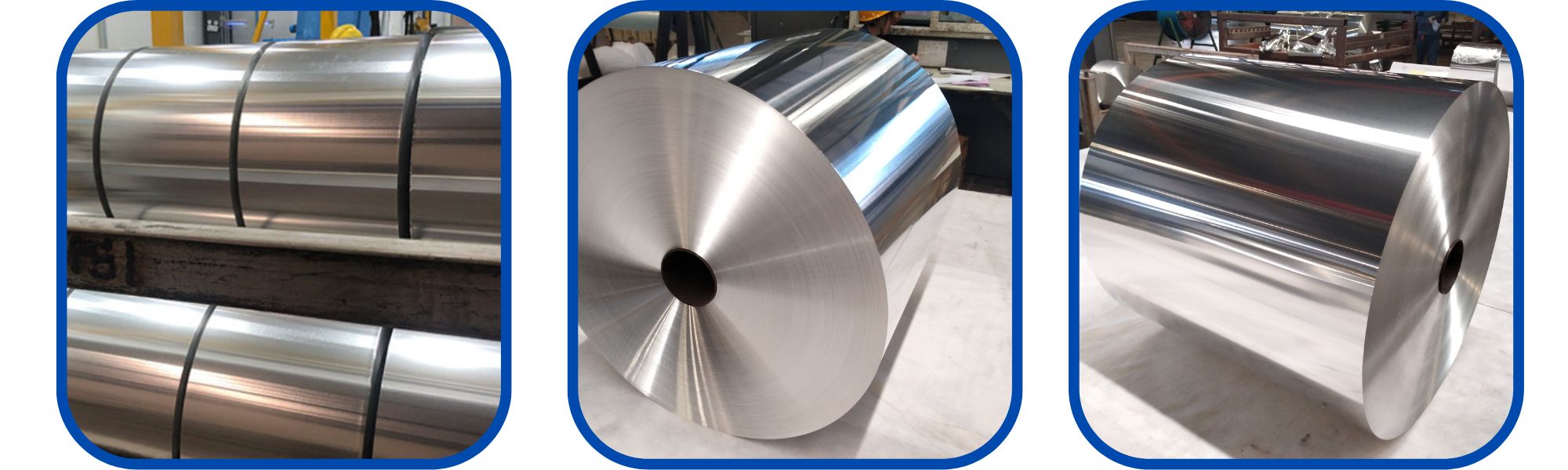

8011 Aluminum foil specified as per standards for thickness, width, surface quality and alloy composition. Standard foil thicknesses range from 0.0005 inches to 0.005 inches. Thinner gauges below 0.001 inches are typically used for lightweight packaging while thicker foils provide reinforcement for heavier duty wraps. Width is usually stated in inches, typical coil widths are 12, 18, 24, 50 and 100 inches. The surface of the 8011 foil looks dull without the anti-slip treatment, although there is the option of a coating if needed. Chemically, 8011 aluminum foil contains about 1.5% manganese for enhanced performance.

Weight is a key consideration that affects material and shipping costs for 8011 aluminum foil. Lighter gauges are more expensive to produce and transport but must still provide the required barrier properties. For foil 12 inches wide, a standard thickness of 0.001 inch weighs about 1.3 pounds per 300 square feet. For comparison, 0.005-inch-thick 8011 foil weighs about 6.5 pounds for the same area. By using the minimum thickness required and seeking volume discounts for larger orders, manufacturers can reduce the weight of 8011 aluminum foil packaging components. Accurately following ordered specifications and minimizing excess material helps to reduce the weight and cost associated with 8011 foil supply.

Household Aluminum Foil Specification

For household foil 8011 aluminum foil jumbo roll,the most widely use is from 8mic to 30mic,the width from 200mm to 600mm.one ton is about 10000 meters,we can produce it according to customer needs.different countries have different requirement.

Household aluminum foil has many uses around the kitchen and home. As a flexible material, foil can be shaped to wrap, line or cover any number of surfaces. It is usually used to wrap food for preservation, baking or reheating. Foil creates an effective barrier that retains moisture and flavor while preventing messes. Foods like chicken, meatloaf and baked potatoes are often wrapped in foil before cooking in the oven or on the grill. Foil is also useful for coating baking pans before adding ingredients. This makes sticky foods like brownies and bars easier to clean up after baking. Foil even enables open-fire cooking and serving, by forming portable wrapping or hanging food packets over the fire.

Alu Foil has additional domestic applications outside of the kitchen. It can be balled up and used to clean appliances such as microwaves or the inside of ovens where baked-on dirt accumulates. A foil of foil under the sink protects the shelving and provides storage of cleaning supplies. Lightly crumpled foil serves as an absorbent packing material to line fragile shipments. Protect furniture from moisture, stains or odors with foil shields when painting, staining or enjoying messy arts and crafts projects. Aluminum foil is also useful for temporary solutions such as patching leaks in roofs, pipes or equipment before making permanent repairs.

Aluminum foil provides consumers with an inexpensive, versatile and effective product for numerous uses for kitchen work, general cleaning and temporary home solutions. Its flexibility, strength and ability to form a tight seal around the edges makes it very suitable for these various roles in home care and maintenance.

HTMM Aluminum Foil Producer

HTMM Aluminum Foil company has been supplying high quality 8011 aluminum foil jumbo roll for over 15 years. We source prime grade aluminum alloy feedstock from trusted partners who adhere to our stringent environmental and sourcing standards. Aluminum enters our facility where it undergoes a rigorous refining and casting process to consistently produce plates with perfect structure specifications. The plates are then cold rolled to the desired thickness and width. Quality checks are conducted throughout to ensure that the 8011 foil meets purity, surface quality and mechanical properties standards.

Our modern foil production facility allows high volumes with tight temperature and atmospheric control throughout the rolling process. This consistency has allowed us to supply foil to major international brands for food packaging, household and industrial markets. As export demand increases, we have invested in expanded warehouse facilities and established overseas distributor relationships. This infrastructure enables us to deliver orders reliably within 2 weeks to customers worldwide anywhere they need 8011 foil.

Our team of metallurgical experts oversee every stage, constantly monitoring processes and introducing innovations to push quality and sustainability. Through research partnerships, we developed strategies to incorporate increased post-industrial recycled materials without sacrificing functionality. A commitment to continuous education and training also means that our manufacturing and administrative teams have the expertise needed for long-term partnerships with customers.

How to choose a high-quality 8011 Aluminum Foil Supplier ?

When you choose us as your 8011 aluminum foil supplier, you have the benefit of a reliable partner dedicated to complete satisfaction. From aluminum mill partnerships to distribution logistics, we control the supply chain to ensure consistent product availability and competitive costs. Partnerships with industry leaders provide assurance of tighter regulation, technical support, and future-ready capacity as aluminum requirements evolve globally. We aim to be your trusted resource for high quality 8011 aluminum foil roll jumbo.

One of our 8011 aluminum foil supplier key advantages is our upstream vertical integration. In addition to our own rolling operations, we have interests in both aluminum smelting and flat rolling product facilities. This ownership structure gives us a direct impact on multiple aspects of the supply chain from base mix production through final gauging. This allows us to source high-quality aluminum feedstock and meet customer requirements promptly with short lead times. Our dedicated logistics team works directly with shipping partners to provide multi-modal transportation. Maintaining control of these key functions means we face less risk of production or delivery being disrupted beyond our control.

As a leading supplier, we are continually innovating to enhance the customer experience of 8011 aluminum foil roll jumbo. Recent investments have expanded our sample bank to include more auxiliary product options such as pre-laminated and metallized samples. Offering evaluation samples beyond the basic gauges, we help customers make early stage decisions. Additional efforts involve leveraging digital tools to streamline ordering and shipping processes. Improvements such as automated order tracking portals and mobile inventory checking apps provide customers with a more convenient way to interact with us online or from their devices. Our goal is to eliminate inefficiencies and bring industry-leading service as both technology and product requirements progress.