The Versatile Material of 30 micron aluminum foil

30 Micron aluminum foil is a remarkably versatile material used in countless applications both in commercial and residential settings. While all aluminum foils share some core properties, 30 micron aluminum foil possesses three key traits that make it particularly well-suited for many uses. These distinguishing characteristics have led 30 micron aluminum foil to become one of the most widely produced and utilized grades of the material. In this article, we will explore the three major properties that define 8011 aluminum foil and have cemented its status as an indispensable product around the world.

Highly Formable

One of the foremost characteristics of 30 Micron Aluminium foil for hookah shisha is its exceptional formability. Formability refers to a material's ability to be shaped, molded, or formed into different structures without incurring damage. This attribute is essential for aluminum foil as it must be able to conform tightly to any shape or surface it comes into contact with. The high formability of 30 Micron Aluminium foil for hookah shisha stems from its alloy composition and physical properties.

As an 8xxx series alloy, 30 Micron Aluminum Foil 8011 For Shisha contains around 0.8-1.2% silicon as its primary alloying element. Silicon significantly enhances the alloy's formability by impeding dislocation movement in the metal structure during shaping processes like rolling. The addition of silicon leads to 30 Micron Aluminum Foil 8011 For Shisha exhibiting a characteristic ductility and malleability that allows it to stretch and mold around complex contours with great ease and precision.

Additionally, 30 Micron Aluminum Foil Jumbo Roll For Shisha has a fine, soft microstructure due to careful thermomechanical processing during production. This microstructure lacks pronounced work hardening, so the metal can readily flow and deform plastically without work-hardening challenges impeding formability. The alloy strikes an ideal balance between strength and ductility, avoiding brittleness on one extreme or softness on the other. As a result, 8011 foil experiences minimal work hardening even under severe forming stresses.

The combination of alloy chemistry, fine microstructure, and optimized strength-ductility profile gives 30 Micron Aluminum Foil Jumbo Roll For Shisha a class-leading ability to intimately wrap around products, fit tightly within packages, and conform to any shape demanded during manufacturing operations. The self-adhering nature of aluminum means 8011 foil maintains continuous intimate contact with surfaces without gaps or wrinkles. This maximizes barrier properties while using minimal material.

If you interested 30 Micron Aluminum Foil. Please contact us.

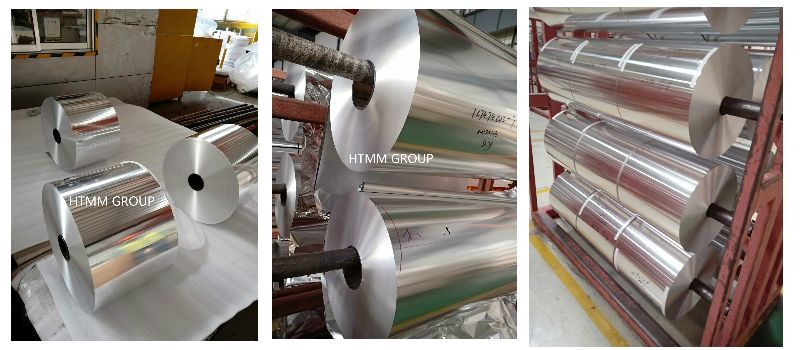

30 Micron Aluminum Foil Jumbo Roll 8011

The high formability of 30 Micron Aluminum Foil Jumbo Roll 8011 For Shisha stems from its alloy composition and physical properties.

The outstanding shapeability allows converters to produce intricate foil liners, lids, and packages with tight seals out of 30 Micron Aluminum Foil Jumbo Roll 8011 For Shisha. End users benefit from a foil that hugs complex container and product designs without tearing, creasing, or springing back out of position. High formability also eases deliverability of 8011 foil through processing equipment without damage. These factors ensure 8011 foil is simple and cost-effective for manufacturers to work with at scale.

Versatile Barrier Properties

Another key attribute of 8011 aluminum foil that facilitates its diverse applications is the material's versatile barrier properties. All aluminum foils provide excellent barriers to light, oxygen, moisture, oils, greases, and bacteria due to the highly impermeable nature of the aluminum metal. However, 8011 foil has been specially engineered to deliver barrier performance across a uniquely wide spectrum of conditions.

Balancing Versatile Barrier Properties

The metallurgy and processing of 8011 aluminum foil have been optimized to offer stability across a wide range of environmental variables like heat, moisture, and pressure without compromising barrier attributes. For example, 8011 foil maintains high impermeability even when subjected to elevated cooking temperatures up to 250°C/500°F or extreme humidity fluctuations. This stability differentiates it from other aluminum foil grades that can experience degraded barrier with thermal or moisture cycling.

The fine microstructure of 8011 aluminum results from controlled cooling during production. This microstructure remains dimensionally stable under the stresses of cooking, sealing, freezing, and other thermal exposures. Combined with a smooth, fully-annealed surface, 8011 foil maintains continuous, intimate contact with packaged surfaces to exclude air and moisture without pinholes or gaps forming. On the other hand, less carefully processed foils may work-harden, distort dimensions, or fail to self-heal small gaps under thermal cycling stresses.

Incorporating a small amount of manganese into the alloy enhances 8011 foil's resistance to humidity without compromising other key attributes. Manganese diffuses to grain boundaries and hinders the penetration and clustering of water molecules at these vulnerable sites. This increases impermeability in high-moisture conditions like food freezing or packaging of moisture-sensitive products.

8011 aluminum foil maintains consistent barrier qualities from freezing temperatures up to 500°F cooking heat without loss of physical or barrier properties. This versatile performance window suits it for an unmatched diversity of packaging and culinary uses compared to alternative foil grades. The ability to maintain a barrier through diverse and changing conditions allows food and product manufacturers to use 8011 foil in more applications with greater confidence.

The metallurgy and processing of 8011 aluminum foil have been optimized to offer stability across a wide range of environmental variables like heat, moisture, and pressure without compromising barrier attributes.

Easy Processing

Further enabling the widespread use of 8011 aluminum foil is its ease of processing during both manufacture and end use. When it comes to manufacturing, the alloy's characteristics assure simple, efficient production through each step from casting and rolling to perforating, slitting, and packaging. On the end use side, characteristics like softness and malleability result in 8011 foil offering user-friendly performance.

Simple Manufacturing

During production, 8011 aluminum's finely tuned strength-ductility balance allows it to undergo heavy deformations through cold rolling without work hardening or cracking concerns. This consistency eases quality control. The smooth, flat surfaces resulting from optimized thermomechanical processing also simplify high-speed printing, coating, and laminating operations downstream.