The "100 microns" (0.1 mm) size is not a random choice, but a golden balance that has been tested with engineering. This thickness achieves the optimal configuration in several key performance areas. Ducts must withstand a certain degree of tension, pressure and bending during installation and use. Too thin aluminum foils (e.g., less than 50 microns) are prone to cracks and perforations during construction, which can lead to leaks and have a serious impact on system efficiency. A thickness of 100 microns provides sufficient mechanical strength, can withstand traditional physical stresses, ensures ducts can pass through complex building structures without damage, and significantly extends life. The core value of flexible ducts is "softness". If the aluminum foil is too thick (e.g., more than 150 microns), the material becomes harder and harder to bend at smaller radii, losing the advantages of flexible tubing. Its thickness of 100 microns provides a perfect balance of strength and flexibility, allowing it to easily bypass obstacles such as beams and pipes and adapt to a variety of irregular Spaces, giving designers and installers great freedom. In air conditioning systems, it is important to prevent energy loss. The 100 micron thick aluminum foil forms a dense barrier with no holes to prevent permeation of air and water vapor. This not only helps to avoid the clean transport of air, but also to prevent that the external moist air causes temperature layer condensation loss, more importantly, it works, combined with the back of the insulation material, with very low thermal conductivity Constifies a constant thermal insulation system and improves the energy efficiency of the entire air conditioning system to minimize the hot-cooling bridge effect.

By inserting this 100 micron thick aluminum foil layer into the structure of the flexible duct, its function can be expressed in all directions. Typical flexible duct adopts multi-layer complex structure, aluminum foil usually exists as lining and outer layer, playing an irreplaceable role. If 100 micron aluminum foil is used as the inner wall of the duct, the surface is extremely smooth and the friction coefficient is low. This reduces the resistance of the air flow and the fan's energy consumption and noise. A smooth airflow passage is very important to maintain the airflow of the system design and to ensure that the air flows out of the end. The 100 micron aluminum foil is often used on the outside of ducts. It's like putting a strong "armor" on the inside insulation (usually glass cotton). This armor prevents wear during construction, light collisions during daily life, and bugs eaten by mice. Due to the characteristics of the metal, it is also fireproof, which can block the spread of the flame for a certain period of time, and can raise the fire safety level of the building. Water vapor is contained in the air, but if the water vapor enters the heat insulation material and condenses at low temperature, the heat insulation property will be damaged and mold will occur. The dense structure of 100 micrometers aluminum foil makes the perfect sealing to prevent the penetration of water vapor.

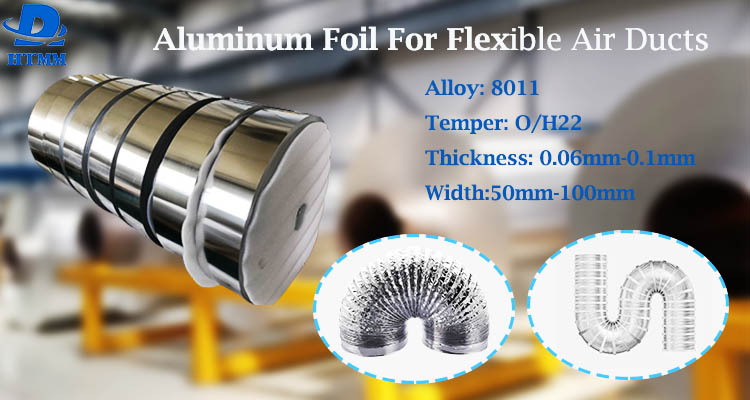

Manufacturing 100 micron aluminum foil flexible ducts is a precise process. Advanced laminating technology combines aluminum foil with reinforced fibers (such as polyester film and glass fiber) and heat insulation. This composite structure makes the duct light and strong.

In today's world where sustainable development is increasingly a global consensus, 100 micrometers of aluminum foil flexible ducts also show the value of its environmental protection. Aluminum is a metal that can be recycled many times and USES only 5% of the energy of the original aluminum. Ducts using aluminum foil can efficiently recover the aluminum material once the life of the building is over, greatly reducing the mining of building waste and primary resources. In addition, its excellent energy-saving performance reduces the energy consumption of air conditioning, thereby reducing many carbon emissions throughout the entire life cycle, and actively contributes to green architecture.

100 micron aluminum foil plays an important role behind seemingly mediocre ducts. With its scientific thickness, excellent physical performance and extensive functionality, it silently supports the stability, high efficiency and safe operation of modern building ventilation system. . It is not only a bridge between space and air, but also a bridge between current technology and future sustainable development. Next, when you enjoy the indoor air and comfortable temperature, remember that this 100 micron thick aluminum foil provides immense energy behind the surface. It is undoubtedly a small and brilliant example of the application of materials of ergonomic wisdom.